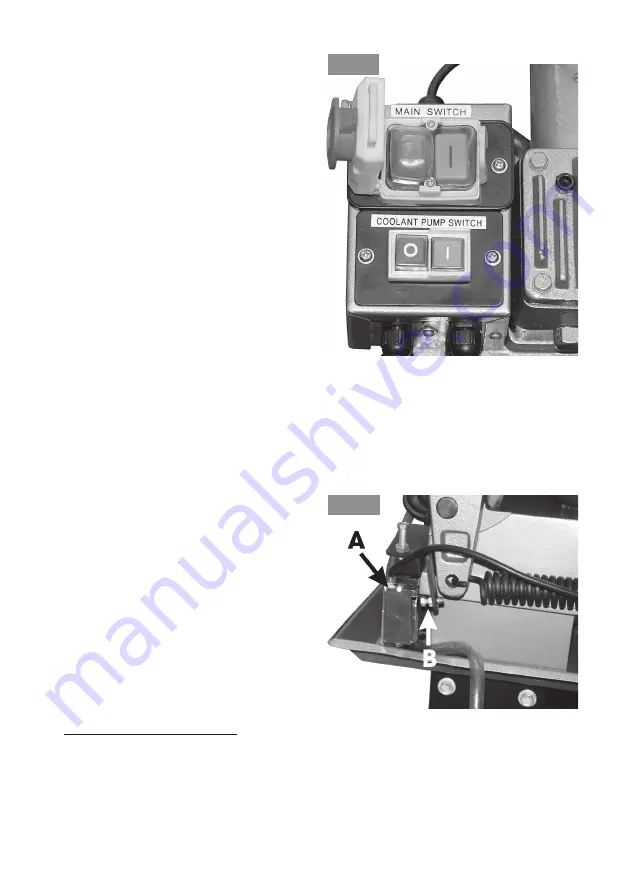

When the Arm reaches the bottom of

its travel, a bracket, attached to the

Arm and carrying an adjuster, shown at

‘B’ Fig.15, activates a microswitch, ‘A’

switching Off the machine. ALWAYS

ensure the adjuster is set so that the

microswitch operates correctly.

‘Running In’ the Blade

To gain the maximum working life from your blade it is also essential for a new

blade to be ‘RUN IN’ for a short period of time. This is done by applying a lighter

cutting pressure on the first few cuts made by the blade. As a guide the ‘Running

In’ cutting pressure should be half the normal cutting pressure. The cut will therefore

take longer to complete.

14

To switch OFF press the RED button

marked ‘O’,

NOTE: If this is the first time you have

operated your machine, or if a new

blade has been installed, allow the

blade to run completely off load for a

few minutes to allow the blade to settle.

With the blade running at full speed,

turn the Lever ‘B’Fig 3a, to the 6 o’clock

position again, then gently turn knob ‘A’

anticlockwise

so that the blade slowly

lowers at the desired rate, until it

contacts the workpiece and cutting

begins. Remember, do not start to cut

on a sharp edge.

At this point, switch ON the coolant

pump by pressing the GREEN button

marked ‘I’ (see Fig.14).

The rate of descent of the Arm determines the cutting rate and is therefore

controlled by the knob ‘A’, Fig 3a.

The cutting rate is dependant upon two main factors.......the type of material and

the thickness of cut, (which may not be constant). It therefore becomes a matter of

‘feel’. Ideally, blade pressure should be not so light so that it simply ‘rubs’ the work,

and not so heavy as to cause the blade to wander off line or ‘grab’ the work.

Fig. 14

Fig. 15

Summary of Contents for CBS7MB

Page 22: ...Spare Parts Diagram 22...

Page 24: ......