Page 10

Clarke

®

American Sanders

Super 7R Operator's Manual

MAINTENANCE

CAUTION:

Maintenance and repairs performed by

unauthorized personnel could result in

damage or injury. Maintenance and

repairs performed by unauthorized

personnel will void your warranty.

Failure to perform maintenance at

recommended intervals may void

warranty.

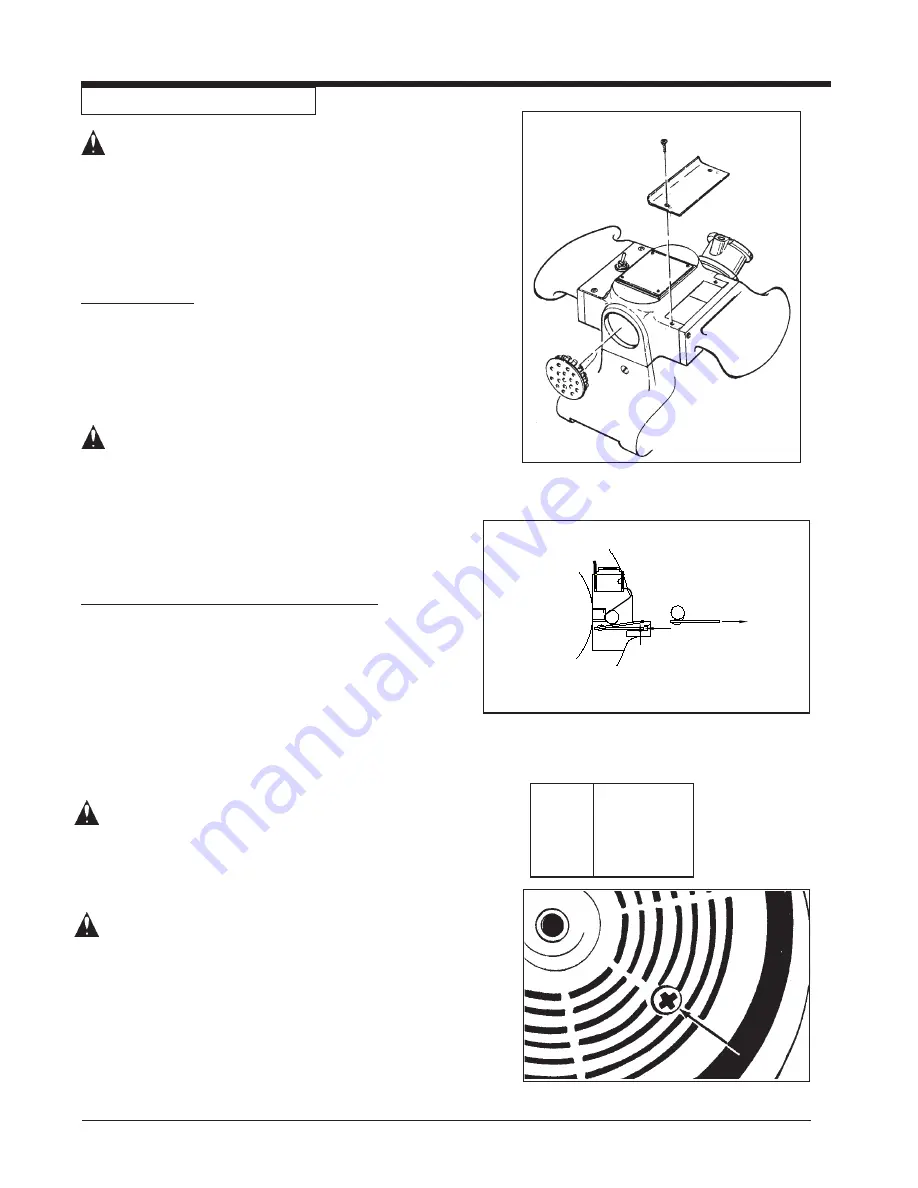

Carbon Brushes

Inspect all four brushes every 6 months or 250 hours.

Access to the brushes is gained through the front and

back motor vent plugs and under both motor covers (figure

6). Press tab on spring clip assembly in, rotate, then

remove (figure 7).Use needlenose pliers to disconnect the

shunt wire. If any brush has worn to 3/8" in length or

shorter, replace the entire set.

CAUTION:

Use only motor brush PN 40818A or

PN 40055A with shunt wire or motor

failure will occur.

When replacing the brushes make sure that the brush

seats against the commutator, the spring rest in the

recess of the brush, and the brush is free to travel. When

returning the switch cover, keep any wires clear of the

commutator and any pinch site.

To Change The Lubricant In The Gearbox

To change the lubricant in the gearbox, follow this proce-

dure:

1. Put the machine upside down on a bench.

2. Align one of the two holes in the rubber pad with one

of the three holes in the rotating wall guard.

3. Align both holes with one of the three screws in the

gear housing cover. Remove the screw from the gear

housing cover. (Figure 8)

4. Align the holes with each of the other two screws,

then remove screws.

CAUTION:

Make sure no dust enters the gear box.

Damage will occur to the gear box.

5. Remove the cover from the gear housing.

6. Remove the old lubricant from the gearbox.

7.Add six ounces of American SandersTechnology

lubricant to the gear box.

CAUTION:

To prevent damage to the motor, do not

add more than six ounces of lubricant to

the gearbox.

8. Using the three screws removed above, install the

cover on the gear housing.

9. Start the machine and let it run for 15 minutes. A

small amount of excess lubricant should flow out the

vent hole. If none appears it may be necessary to

add additional lubricant.

10. Wipe off excess lubricant and clear vent hole.

Figure 8

Qty

Part No.

1Qt.

16610A

1Gal.

16611A

Lubricants

Figure 6

Figure 7