13

5. Periodically lubricate the tail-stock, copy stock and tool carrier screw

threads with engine oil such as SAE30 grade if they become stiff to use.

6. Lightly lubricate the tail-stock and tool-post locking handles with oil if they

become difficult to use.

•

The ball bearings in the headstock and tail-stock spindles and in the copy

live roller pin are greased and permanently sealed at the factory and

require no further lubrication.

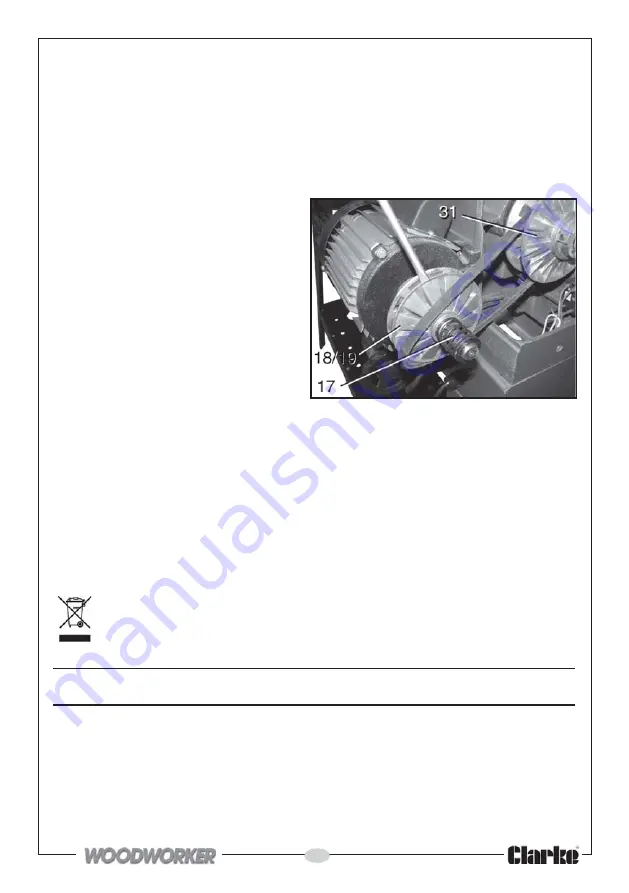

REPLACING THE BELT

1. Undo the retaining screws and

remove the belt guard.

2. By pushing the speed control

lever, expand the two halves of

the driven pulley (31) allowing

the belt to adopt its smallest

diameter at this end.

3. Rotate the motor pulley (18/19)

to dismount the drive belt from it

and then lift it off the driven

pulley.

4. Replacement is a reverse of the removal procedure. A broad-bladed

screwdriver or similar will be useful to prize the two halves of the motor

pulley apart against the pressure of the spring (17). Ensure the left & right

halves of the drive pulley spring back to grip the belt and that the belt is in

tension.

In case of problems refer to TROUBLESHOOTING on page 14. If you are unable

to rectify any faults, please contact your local dealer or Clarke International

Service Department on 0208 988 7400 for assistance.

ENVIRONMENTAL PROTECTION

Do not dispose of this product or broken components with general

household waste. All tools, accessories and packaging should be

sorted, taken to a recycling centre and disposed of according to the

laws governing Waste Electrical and Electronic Equipment.

ACCESSORIES

The following range of accessories are also available from your Clarke dealer:

8-Piece Chisel Set

Part No: 6500649

4-Jaw Independent Lathe Chuck

Part No: 6500645

1/2” Cap. Tailstock Chuck

Part No: 6500643

Fig 6

Summary of Contents for 6500682

Page 19: ...19 DECLARATION OF CONFORMITY...

Page 20: ......