10

Parts & Service: 020 8988 7400/E-mail:[email protected] or [email protected]

BEFORE USE

FITTING / ADJUSTING THE DISC GUARD

Slide the disc guard over the end of

the grinder.

Rotate the guard to the required

position and secure by tightening the

screw into the square nut until the

guard is clamped in place.

The guard should be fitted to give

maximum protection from the disc

when fitted in the working position.

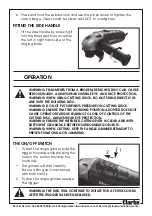

FITTING/REMOVING THE DISC

Ensure the disc guard is correctly fitted before installing the disc.

WARNING: MAKE SURE THAT THE GRINDER IS SWITCHED OFF AND

UNPLUGGED FROM THE MAINS SUPPLY BEFORE FITTING OR REMOVING

THE DISC.

1. Press and hold the spindle lock

button.

•

You may need to turn the spindle

by hand to fully engage the

spindle lock.

2. Use the pin spanner supplied to

loosen & remove the outer flange.

3. Ensure that the inner flange is

fitted correctly with the raised flat

surfaces pointing inwards as

shown to engage with the flat

section on the spindle.

4. Place the grinding disc over the spindle to sit on the inner flange.

•

If the grinding wheel supplied is a ‘Depressed Centre’type, mount it as

shown, i.e. with the depressed centre towards the machine.

•

For standard discs ensure the raised section of the outer flange is pointing

towards the disc.

5. Screw on the outer flange with the centre boss facing inwards so as to sit

inside the apperture of the disc. Tighten securely with the pin spanner.

•

When using thin discs, the outer flange can be reversed so that the raised

section is pointing away from the disc.

Disc Outer flange

pin spanner

Raised surface

of inner flange