10

Parts & Service: 020 8988 7400/E-mail:[email protected] or [email protected]

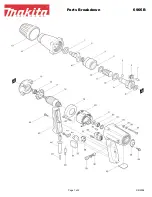

SERVICE AND REPAIRS

1. Keep the tool clean at all times, and ensure that the bolts securing the

case remain tight.

•

All bearings etc, in this machine are lubricated with sufficient high grade

lubricant for the machines lifetime under normal operating conditions,

therefore no further lubrication is required.

•

Be aware that outside factors may effect the wrench’s operation and

efficiency, These may include reduced compressor output, excessive

drain on the airline, moisture in suspension or restrictions in the line, or the

use of connectors of improper size or poor condition which will reduce air

supply.

•

Any major servicing and repairs should be carried out by your local

CLARKE dealer or a qualified service technician.

STORAGE

1. Store the tool safely in its box in a dry, secure environment.

2. If the tool is not to be used for longer than 24 hours, run a few drops of

CLARKE airline oil into the air inlet and run the tool for a few seconds to

ensure that the oil has been well distributed throughout the tool.

3. When storing, ensure the blanking plug is replaced on the airline

connector once the airline has been disconnected.

**Clarke Airline Oil is available from your CLARKE dealer: part no. 3050825

ACCESSORIES

A wide range of airline accessories is available from your nearest CLARKE

dealer, for further information, contact your nearest dealer, or telephone

CLARKE International Sales department on 01992 565300.

Suitable air line accessories include Air Filter/Regulators, Lubricators, Hoses,

Snap Couplings, clips, gauges, valves.

Suitable Impact Wrench compatible socket sets include the following:

3110437

CAT37B

11 piece 1/2”square drive(metric)

1800310

CIS12/17

17 piece 1/2”square drive(metric/AF)

1800305

CIS9/32

32 piece 3/8” & 1/2”square drive (metric/AF)

1800345

CIS12/7M

7 piece 1/2”square drive universal joint (metric)

1800350

CIS12/7MD

7 piece 1/2”square drive universal joint (deep) metric

1800355

CIS12/6H

6 piece 1/2”square drive hex key set (metric)

1800360

CIS12/6S

7 piece 1/2”square drive TRX-Star

Summary of Contents for 3110805

Page 18: ......