47

Troubleshooting

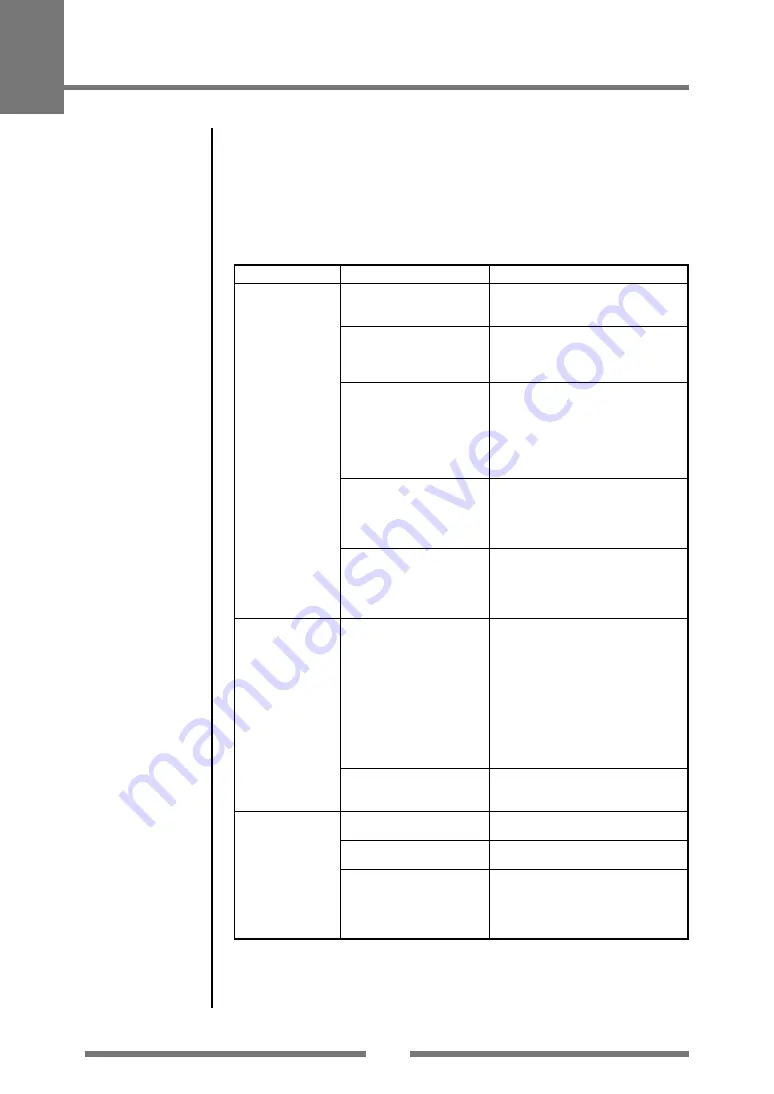

Indication

The LED do not light

up when printer

power is connected.

Paper is feeding, but

nothing is printed.

The printer is not

printing neatly.

Corrective action

1) Insert the plug of the power cord

correctly in the electric outlet.

2) Insert the connector of the power cord

correctly into the power inlet of the

printer.

3) Replace the power cord. Consult with

the dealer where the printer was

purchased to make sure you obtain a

cord made especially for the printer.

Note:

Do not use any power cord

except one made especially for the

printer.

4) Check to make sure power is supplied

to the outlet. If there are any problems,

make sure power is supplied to the

building. Or find out if a power failure

has occurred.

5) If necessary, replace the main fuse in

the building’s fuse box, and reset the

m a i n b re a ke r. As k a q u a l i f i e d

s e r v i c e m a n to c a r r y o u t t h e

replacement.

1) If it is dirty, remove the dirt with the

attached head cleaner.

If a label is stuck to the thermal

printhead remove it.

Note:

Do not use a metal object to

remove a label stuck to the inside of

the printer. (This may damage the

thermal printhead.) If adhesive label

material is stuck to the thermal

printhead, remove it with a soft cloth

soaked in ethyl alcohol.

2) Use the recommended ribbon or a

ribbon of the same type.

1) Correctly set the media and the ribbon.

2) Set the appropriate printing density

using the menu or control software.

3) If it is dirty, clean it with ethyl alcohol.

If it is deformed, replace it.

Note:

Consult with the dealer that

supplied the printer concerning the

replacement.

This chapter explains corrective actions taken when the printer malfunctions or when

an error message is displayed.

Items to check when a malfunction occurs

When the printer malfunctions during operation, take corrective action with reference

to the following table. If the corrective action does not solve the problem, consult

with the service personnel at the dealer where you purchased the printer.

Check

1) Is the plug of the power

cord correctly inserted into

the electric outlet?

2) Is the connector of the

power cord correctly

inserted into the power

inlet of the printer?

3) I s t h e p o w e r c o r d

damaged?

4) Is power supplied to the

electric outlet the printer

is connected to?

5) Is the main fuse in the

building’s fuse box burnt

out?

1) Is the thermal printhead

dirty?

Is a label stuck to the

head?

2) I s t h e re c o m m e n d e d

ribbon or a ribbon of the

same type used?

1) Are the media and the

ribbon correctly set?

2) Is the printing density too

high or too low?

3) Is the platen dirty?

Is it deformed?

Installing the Media (p.23)

Setting method (p.26)

4

Troubleshooting