8

HEAT PUMPS - AIR CONDITIONING - REFRIGERATION - AIR HANDLING - HEAT EXCHANGE - NA 14.712 A

Comfort units

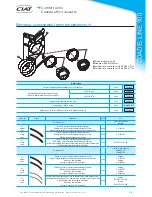

Coanda effect cassette

COADIS LINE 900

t

eChniCaL

ChaRaCteRistiCs

Motor electrical specifications

- Motor operating range: minimum return T°C: 0°C

maximum return T°: 40°C

COADIS LINE 900

Motor

code

AC asynchronous motor

HEE Brushless motor

922

932

932SP

924

934

934SP

922

932

932SP

924

934

934SP

Input power (W)

V5

102

102

157

102

102

157

51

51

113

51

51

113

V4

89

89

136

89

89

136

38

38

91

38

38

91

V3

69

69

119

69

69

119

24

24

72

24

24

72

V2

53

53

105

53

53

105

15

15

56

15

15

56

V1

35

35

93

35

35

93

10

10

42

10

10

42

Input current (A)

V5

0.44

0.44

0.68

0.44

0.44

0.68

0.37

0.37

0.39

0.37

0.37

0.39

V4

0.39

0.39

0.59

0.39

0.39

0.59

0.28

0.28

0.61

0.28

0.28

0.61

V3

0.30

0.30

0.52

0.30

0.30

0.52

0.20

0.20

0.50

0.20

0.20

0.50

V2

0.23

0.23

0.46

0.23

0.23

0.46

0.14

0.14

0.39

0.14

0.14

0.39

V1

0.15

0.15

0.40

0.15

0.15

0.40

0.10

0.10

0.31

0.10

0.10

0.31

Important:

The new European ErP (Energy related Products) directive applies to all manufacturers of equipment fitted with a fan with a

power input of between 125 watts and 500 kilowatts (inclusive); in this directive, the European Union specifies the minimum

efficiency values which must be respected for this equipment to be authorised for use within its territory.

The 1st stage of this directive is applicable from 1st January 2013 and establishes more stringent requirements for fan energy

efficiency. A second stage to come into force in 2015 will extend these requirements further. The aim is to ensure that fans are

more energy efficient so that they contribute to the reduction in CO2 emissions of at least 20% by 2020 as stipulated in the

Kyoto agreement, and to promote the use of low energy motors.

USE OF COADIS LINE PRODUCTS IN ESTABLISHMENTS OPEN TO THE PUBLIC

APPLICABLE FROM 1 JANUARY 2013

COADIS LINE 600 (all sizes)

Eurozone

Outside of Eurozone

With 5-speed asynchronous motor

OK

With HEE motor

COADIS LINE 900

Eurozone

Outside of Eurozone

With 5-speed asynchronous motor

922 ; 924

OK

OK

932 ; 934

932SP; 934SP

NO

With HEE motor

922 ; 924

OK

OK

932 ; 934

932SP; 934SP

ErP

READY