9

machine’s surface.

The lathe net weight is 330kg, stand weight is 60kg. When lifting, must keep the machine

in balance and avoid tilting.

The carriage, tailstock and other slide parts of the lathe are locked before leaving factory.

Don’t loosen these when lifting and should inspect to confirm whether they are locked or not in

order to prevent the parts sliding to make danger. Carefully put the machine on the base or stand

which have been fixed and fix the machine to the base or stand by bolt and nut.

7.3 CLEANING

Prior to shipment all machine and finished surfaces are coated to prevent rusting. Before

moving the carriage or tailstock, use clean solvent to remove the rust preventive coating, use

brush and solvent to clean the lead screw, rack, feed -rod, etc. Move the saddle, carriage and

tailstock to cleaned direction about 300mm, clean the ways for any residue of rust preventive

coating. Move the other way the same distance and repeat the process. Such care in the cleaning

will ensure the removal of any foreign particles and prevent the way scoring.

Lubricate the ways when clean finished.

8. LEVELING

The lathe should be kept perfectly level at all times.

LEVELING PROCEDURE:

A. Longitudinal leveling

After the bed-

ways are dry after cleaning, back off the base screws, place a 6” precision

machinist spirit level over working table along longitudinal direction ( bed length direction )

move the working table at the headstock end along bed length direction, make leveling by

adjusting the adjustable iron spacer, obtain a reading. Then move the working table to the

tailstock, adjust the screw of the adjustable iron spacer until the spirit level obtain the same

reading as on the headstock end.

put the spirit level on the headstock end put the spirit level on tailstock end

B. CROSS LEVELING

Put the spirit level on the working table alo ng cross direction ( bed width direction ), move

the working table to the headstock end along bed length direction, take a reading, then move the

working table to the tailstock end, the reading at this end must be exactly the same as the other

end. No twist is permissible. If the reading is not same, adjust the screw of the adjustable iron

Summary of Contents for CZ1224

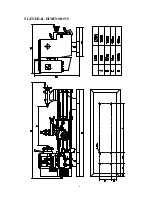

Page 7: ...6 5 GENERAL DIMENSIONS ...