05

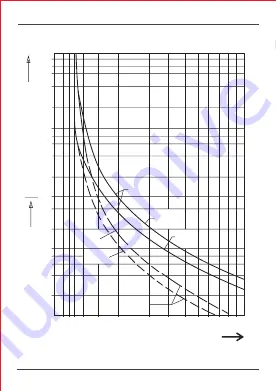

Figure 1 Thermal relay operation time – current characteristic curve

S

1

2

4

6

8

10

20

40

1

2

4

6

8

10

20

40

60

80

100

120

0.8

1 1

.

2

1

.

5

2

3

4

5

6 7 8 9 10

min

heat state

3 phase

2 phase

cold state

2 phase

3 phase

Amplification factor of setting current