チコーエアーテック株式会社

Copyright CHIKO AIRTEC CO., LTD. 2009

8

4

操作

Operation

4.1

電源について

Power supply

本機の電源は、単相電源です。

The power supply is single-phase,

CBA-1300AT2-HC

:

100V

~

115V

50/60Hz

CBA-1300AT2-HC-T

:

200V

~

240V

50/60Hz

CBA-1300AT2-HC

(

200V

):

200V

~

240V

50/60Hz

供給電圧の許容範囲は、±

10

%です。

電源コード(コード長さ

3m

)付きです。(アース付プラグ)

The allowable supply voltage range is ±10%.

The power cable of 3 m with a grounding plug is included.

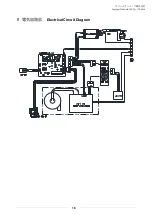

4.2

AT

パネルについて

AT panel

異なった電源で運転されますと、故障の原因になります。

Operating the product with a different power supply may cause a failure.

3

分以上のインターバルをおいて、

ON/OFF

の操作を行ってください。

それ未満、特に

30

秒未満の

ON/OFF

を繰り返すと故障の原因となります。

Allow an interval of at least three minutes before turning the equipment ON or

OFF. If the equipment is turned ON or OFF repeatedly at a shorter interval,

particularly within 30 seconds,it may malfunction.

④ 圧力不足

Insufficient Pressure

Pressure down

⑤ 風量不足

Insufficient Airflow

Volume down

⑥ 運転圧力表示

Static pressure

Level(KPa)

Operating Pressure Indication

⑦ 能力レベル Volume

Capacity Level

③ Hi ボタン

Hi button

① ON ボタン

ON button

③ Lo ボタン

Lo button

② OFF ボタン

OFF button