E N G I N E E L E C T R IC A L

6 Y - 2 5

IGNITION SYSTEMS

INDEX

General Description........................................................ 6Y-25

Theory of Operation....................................................... 6Y-27

Components...................................................................... 6Y-28

Distributors..................................................................... 6Y-28

Spark Advance Systems............................................. 6Y-28

Cam A ngle..................................................................... 6Y- 31

Ignition Condenser (Capacitor)............................... 6Y-31

Ignition Coil................................................................... 6Y -32

Spark Plugs..................................................................... 6Y -32

Secondary Ignition Cables......................................... 6Y-33

Ignition Switch.............................................................. 6Y- 33

Adjustments and Repairs............................................... 6Y-35

Distributor Contact Points........................................... 6Y-35

Cleaning.......................................................................... 6Y- 35

Replacement................................................................... 6Y -35

Setting Dwell Angle.................................................... 6Y -37

Distributor Condenser................................................... 6Y- 38

Performance Diagnosis............................................... 6Y- 38

Replacement.....................................................................6Y- 38

Distributor......................................................................... 6Y- 39

Removal...........................................................................

Disassembly.................................................................... 6Y-39

Cleaning and Inspection............................................ 6Y- 40

Assembly......................................................................... 6Y-40

Installation...................................................................... 6Y-41

Off-Engine T est............................................................... 6Y-42

Coil Replacement.............................................................. 6Y-42

Spark Plug and Wire Service...................................... 6Y-42

Removal and Inspection.................................................6Y-42

Spark Plug Cleaning..................................................... 6Y-43

Adjust Plug G ap............................................................. 6Y-43

Installation of Plugs...................................................... 6Y-43

Installation of Plug W ires........................................... 6Y-43

Diagnosis.............................................................................. 6Y-44

Ignition System................................................................ 6Y-44

Ignition Coil T est........................................................... 6Y-45

Distributor Condenser Test........................................ 6Y-46

Ignition System Resistance T est............................... 6Y-47

Spark Plugs....................................................................... 6Y-47

GENERAL DESCRIPTION

The ignition system used on all models is the standard

breaker point type consisting of a coil, condenser,

distributor, switch, wiring, spark plugs and a source of

electrical energy. The distributor contact points set,

condenser, cam lubricator and spark plugs are the only

system components that require periodic service. The

remainder of the ignition system requires only periodic

inspection to check the operation of the components,

tightness of electrical connections, and condition of the

wiring.

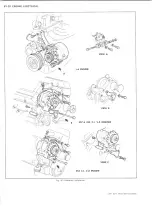

Two types of distributors are used: an internal

adjustment distributor on 6 cylinder engines (fig. li) and

an external adjustment distributor on 8 cylinder engines

(fig. 2i). Both function in much the same manner to - (1)

cause a higher voltage surge from coil, (2) time these

surges with regard to engine requirements through use of

centrifugal and vacuum advance mechanisms, and (3)

direct high voltage surges through distributor rotor, cap,

and high tension wiring to the spark plugs.

The distributor houses the contact points that make and

break the primary circuit, and also directs high voltage

and current in proper sequence to the spark plugs. The

contact point set is replaced as a complete assembly. The

breaker lever spring tension and point alignment on the

replacement set are factory adjusted, leaving only the

dwell angle to be adjusted after installation.

The distributors are equipped with a cam lubricator,

which should be rotated 180 degrees every 12,000 miles

and replaced every 24,000 miles. Do not attempt to

lubricate the element, but replace when necessary.

Distributor shaft lubrication is accomplished by a

reservoir of lube around the mainshaft in the distributor

bowl.

The rotor located above the breaker plate assembly

serves as a cover for the centrifugal advance mechanism,

and distributes high voltage and current to fire the spark

plugs. When the rotor is removed, the centrifugal

advance mechanism should be inspected for lubricant. If

necessary, a small amount of cam and bearing lubricant

should be applied to the advance weights.

The ignition coil (fig. 3i) is an oil filled, hermetically

sealed unit designed specifically for use with an external

resistance. The number of turns in the primary winding

results in a high inductance in this winding, which makes

it possible for the coil to provide a higher secondary

voltage output throughout the speed range. The primary

current from the ignition switch passes through a

resistance wire which lowers the voltage to approx

imately 8 volts. This lower voltage provides for longer

contact life.

For optimum starting performance, the resistance is

bypassed during cranking, thereby connecting the

ignition coil directly to the battery. This provides full

battery voltage at the coil and keeps ignition voltage as

LIGHT DUTY TRUCK SERVICE MANUAL

Summary of Contents for Light Duty Truck 1973

Page 1: ......

Page 4: ......

Page 6: ......

Page 53: ...HEATER AND AIR CONDITIONING 1A 27 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 115: ...LIGHT DUTY TRUCK SERVICE M A N U A L HEATER AND AIR CONDITIONING 1A 89...

Page 123: ...BODY 1B 3 Fig 6 Typical 06 Van LIGHT DUTY TRUCK SERVICE MANUAL...

Page 149: ...BODY 1B 29 Fig 84 Body Mounting 06 Fig 85 Body Mounting 14 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 171: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 2 Frame Horizontal Checking Typical FRAME 2 3...

Page 173: ...LIGHT DUTY TRUCK SERVICE M A N U A L Fig 4 10 30 Series Truck Frame FRAME 2 5...

Page 174: ...2 6 FRAME LIGHT DUTY TRUCK SERVICE MANUAL Fig 5 Underbody Reference Points G Van...

Page 185: ...FRONT SUSPENSION 3 11 Fig 16 Toe out on Turns LIGHT DUTY TRUCK SERVICE MANUAL...

Page 224: ......

Page 266: ......

Page 351: ...ENGINE 6 15 Fig ID Sectional View of Eight Cylinder Engine LIGHT DUTY TRUCK SERVICE MANUAL...

Page 375: ...EN G IN E 6 39 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 376: ...6 4 0 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 377: ...ENG IN E 6 41 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 378: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 37L K Series Engine Front Mount 6 42 ENG INE...

Page 400: ...6 6 4 ENG INE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 401: ...ENG IN E 6 65 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 402: ...6 6 6 ENGINE LIGHT DUTY TRUCK SERVICE MANUAL...

Page 403: ...E NG IN E 6 67 Fig 36V C Series Engine Mounts LIGHT DUTY TRUCK SERVICE MANUAL...

Page 410: ......

Page 423: ...EN G IN E C OOLING 6K 13 Fig 16 Overheating Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 424: ...6 K 1 4 ENG INE COOLING Fig 17 Coolant Loss Chart LIGHT DUTY TRUCK SERVICE MANUAL...

Page 456: ...6M 32 ENGINE FUEL Fig K15 Accelerator Controls G Van L 6 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 492: ......

Page 512: ...Fig 18e Vacuum Advance Diagram V8 Engine...

Page 516: ...6 T 2 4 E M IS S IO N CONTROL SYSTEMS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 528: ......

Page 590: ......

Page 593: ...CLUTCHES MANUAL TRANSMISSIONS 7M 3 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 598: ...7M 8 CLUTCHES MANUAL TRANSMISSIONS LIGHT DUTY TRUCK SERVICE MANUAL...

Page 642: ......

Page 654: ......

Page 743: ...FUEL TANKS AND EXHAUST 8 13 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 744: ...8 14 FUEL TANKS AND EXHAUST LIGHT DUTY TRUCK SERVICE MANUAL...

Page 760: ...8 30 FUEL TANKS AND EXHAUST Fig 40 Exhaust Pipe P Models LIGHT DUTY TRUCK SERVICE MANUAL...

Page 761: ...FUEL TANKS AND EXHAUST 8 31 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 763: ...FUEL TANKS AND EXHAUST 8 33 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 766: ......

Page 832: ...LIGHT DUTY TRUCK SERVICE MANUAL Fig 106 Power Steering Pump Mounting Typical 9 66 STEERING...

Page 833: ...PUMP ASSEMBLY STEERING GEAR TYPICAL SMALL V8 TYPICAL LARGE V8 STEERING 9 67...

Page 861: ...STEERING 9 95 Fig 134 Power Steering Pump Leakage LIGHT DUTY TRUCK SERVICE MANUAL...

Page 864: ......

Page 876: ......

Page 886: ...11 10 CHASSIS SHEET METAL LIGHT DUTY TRUCK SERVICE MANUAL...

Page 891: ...ELECTRICAL BODY AND CHASSIS 12 5 LIGHT DUTY TRUCK SERVICE MANUAL...

Page 934: ......

Page 942: ......

Page 970: ......

Page 972: ......

Page 974: ......

Page 976: ...V...

Page 978: ......

Page 979: ......