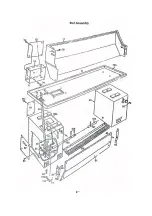

Cross Slide and Compound Rest

The graduations on the handwheel is in millimetres. The dovetails have been fitted with gibs

to allow for adjustments to be made. Make sure that the dovetails are clean and are greased

thoroughly before any adjustments.

To adjust the gib strips, first loosen the rear set screw and then turn the front screw until the

slide moves smoothly without backlash, before tightening the rear set screw. Provision has

been made for the elimination of the backlash in the cross-slide nut. Remove the dust plate

mounting on the rear face of the carriage groove. Turn the cross slide handwheel to move

the cross-feed nut until it reached the end edge of the feed leadscrew and then turn the

socket screw clockwise as required. A 45

turn of the socket screw eliminates approx.

0.125mm of backlash. Keep checking the cross slide until the backlash moves smoothly.

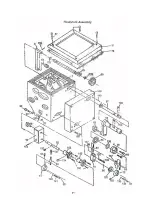

Tailstock

The tailstock can be moved freely on the bed and clamped at any position by using the locking

lever A, the tailstock quill can also be moved forwards and backwards and locked in position

using lever B. For precise adjustment, the tailstock can be adjusted in the cross direction by

turning the socket screw clockwise or counter clockwise as required. Release the clamping

lever A and adjust the setscrews on either side of the tailstock body.

Place a steel bar that is approx. 300mm in length between the centres and measure with a

dial gauge mounted on the saddle to see if the distances on both ends are the same.

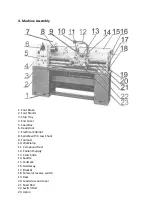

Summary of Contents for Coventry Pro

Page 16: ...Parts List and Diagrams...

Page 17: ......

Page 18: ......

Page 19: ......

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ......

Page 37: ......

Page 38: ......

Page 39: ......

Page 40: ......

Page 41: ......

Page 42: ......

Page 43: ......

Page 44: ......

Page 45: ......

Page 46: ......

Page 47: ......

Page 48: ......

Page 49: ......