9

<Figure A> shows the pulse wave by a eccentric cam for a general metering pump. The pulse of metering

pumps generates when the eccentric cam is used to convert the power of the motor into reciprocating

motions. This eccentric cam is a circular object with the eccentric amount of e, so the reciprocating velocity of

the diaphragm has sinusoidal wave. This is why the discharge flow rate has pulses.

Fig. B Pulseless metering pump(Single head)

Diaphragm

Check Ball

Slider

Niddle bearing

Velocity cam

Constant velocity wave by a constant velocity cam

1 Rotation

Capacity

discharge

Suction

Instantaneous

Discharge

Fig. B Pulseless metering pump constant velocity wave by a constant velocity cam

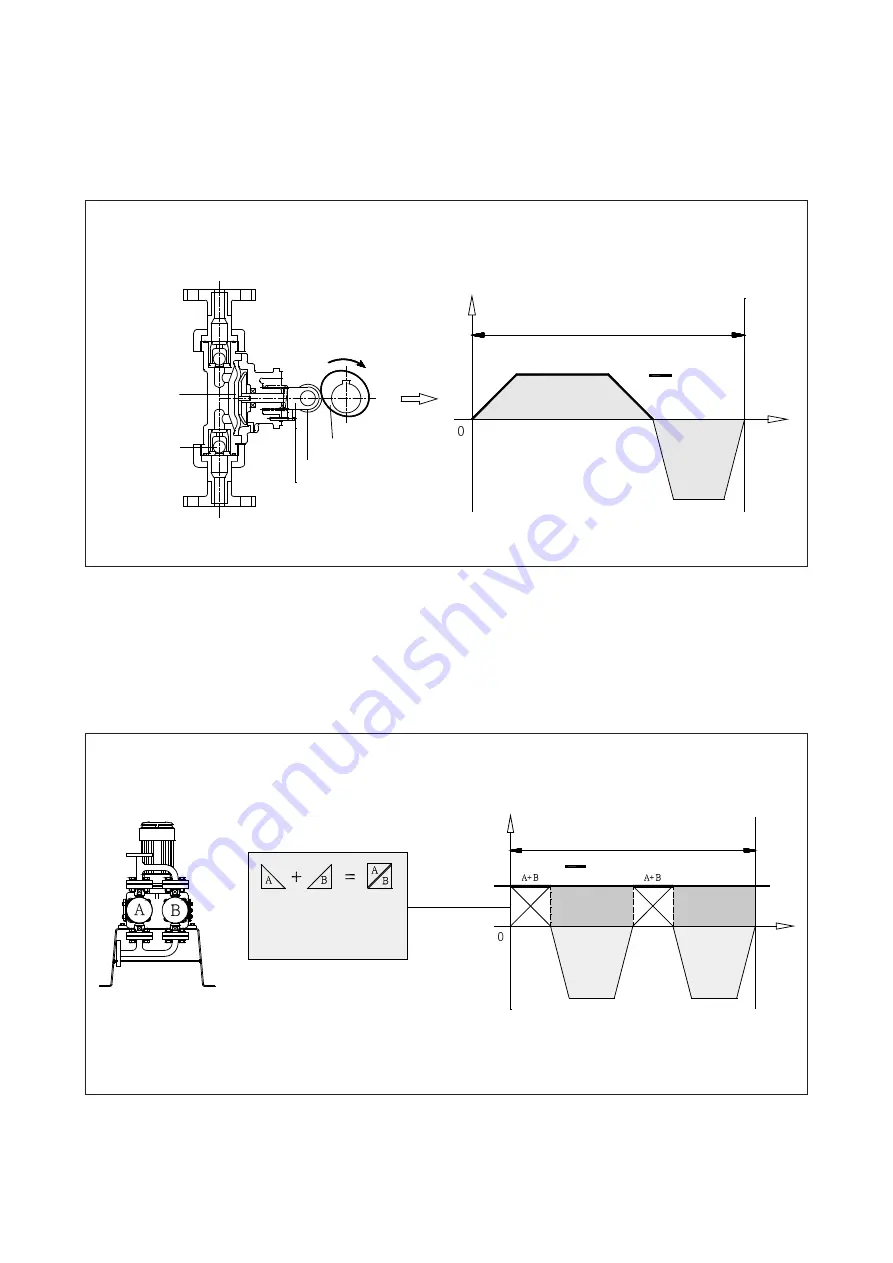

<Figure B> shows the pulse wave of a constant velocity cam, having a constant velocity section in the flow

rate. Because the constant velocity cam operates the diaphragm in a constant velocity, the discharge flow

rate is constant, too. The constant flow rate in this section is the pulseless flow rate. However, the

reciprocating metering pump always has a suction section if it has a discharge one, so in order to obtain

constant pulseless flow rate, two wet sides should be used to have constant discharge.

Fig. C Pulseless metering pump(Double head)

Implementation of pulseless line by using

a constant velocity cam and two wet sides

1 Rotation

Capacity

Discharge is constantly

kept because an interial

A and an interial B are

piled up.

A discharge

B discharge

A

Suction

B

Suction

Instantaneous Discharge

Fig. C Pulseless metering pump implementation of pulseless line by using a constant

velocity cam and two wet sides