11

REV 93520-20130425

ENGLISH

93520

ASSEMBLy

6. Start Engine. Extend and retract the wedge to purge

air from the hydraulic system. When the wedge

motion is smooth, the system is properly purged.

7. Stop the engine and check the hydraulic oil tank

sight glass. Add approximately 1 to 2 gallons

(3.79 to 7.6 L) of hydraulic oil to bring the level

back up to the sight glass.

8. Check oil level daily and add as needed.

A

B

Add Hydraulic Oil

1. Make sure the log splitter is on a flat, level surface.

2. Remove the oil plug from the oil tank. (A)

3. Add 7 gal. (26.5 L) of hydraulic oil - 10W AW32,

ASLE H-150, or ISO 32 are all acceptable types of

fluid.

4. Check the hydraulic oil level using the oil sight

glass. Oil level should visibly fill the glass sight. (B)

5. Replace and tighten the oil plug and orient the vent

hole away from the operator zone.

8) Install the Log Catcher

1. Attach log catcher to side of beam with four M10x15

bolts, M10 lock washers, and M10 washers.

2. Repeat step 1 for the other side.

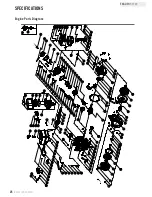

High Pressure Hose

– This is the only hose with steel connectors crimped

on both ends.

– One end connects to the Control Valve (sealed with

teflon tape).

– Other end connects to the top of the Pump (sealed

by O-Ring).

– Because of the male/female ends, this hose only fits

the correct way.

Suction Hose

– This is the clear hose that connects the hydraulic

tank to the pump inlet.

– Both ends of the hose are secured with hose clamps

Oil Return Hose

– This hose returns the oil exiting the cylinder to the

tank.

– It has no connectors crimped onto it.

– The hose ends push over barbed fittings on the

control valve and the oil filter.

– Both ends are secured with hose clamps.

– Notice how the hose is placed through the retainer

ring on the beam. This holds the hose close to the

frame so it does not flop out beyond the wheels (and

catch on things while towing).

7) Install the Engine and Hoses Cont’d.