5

Commissioning

Initial switch-on / functional test with terminal control

22

Carrying out the functional test

1.

Start drive:

1.

Start inverter: X3/DI1 = HIGH.

2.

Activate preset frequency setpoint 1 (20 Hz) as speed setpoint: X3/DI4 = HIGH.

The drive rotates with 20 Hz.

3.

Optional: activate the function for the reversal of rotation direction.

a)

X3/DI3 = HIGH.

The drive rotates with 20 Hz in the opposite direction.

b)

Deactivate the function for the reversal of rotation direction again: X3/DI3 = LOW.

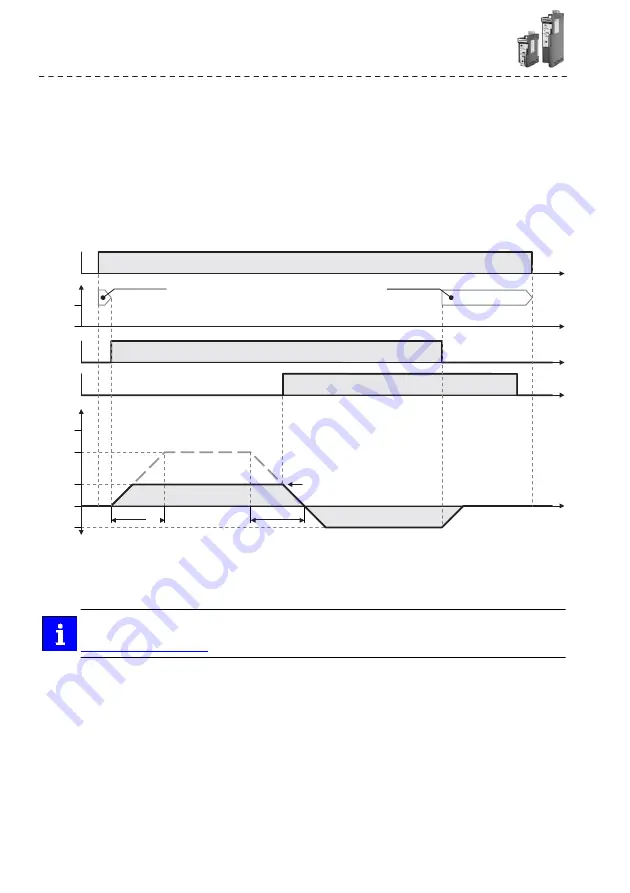

Speed characteristic (example)

DI1

Drive follows frequency setpoint

AI1 [V]

10

0

DI4

Speed setpoint selection via X3/AI1 active

t

(In this example X3/AI1 is connected to GND)

t

Preset frequency setpoint 1 active

DI3

t

Invert rotation active

t

f

set

[Hz]

60

50

20

0

-20

2.

Stop drive:

5 s

5 s

Preset frequency

setpoint 1 (20 Hz)

t

1.

Deactivate preset frequency setpoint 1 again: X3/DI4 = LOW.

2.

Stop inverter again: X3/DI1 = LOW.

The functional test is completed.

The commissioning process of the drive solution is described in a separate commissioning instruc-

tion which can be found on the Internet in our download area:

services-support/file-archive/