Page 6

For technical questions, please call 1-800-444-3353.

SKU 67708

20. People with pacemakers should

consult their physician(s) before use.

Electromagnetic fields in close proximity

to heart pacemaker could cause

pacemaker interference or pacemaker

failure.

21. WARNING: The brass components of

this product contain lead, a chemical

known to the State of California to cause

birth defects (or other reproductive

harm). (California Health & Safety code

§ 25249.5,

et seq.

)

22. The warnings, precautions, and

instructions discussed in this instruction

manual cannot cover all possible

conditions and situations that may occur.

It must be understood by the operator

that common sense and caution are

factors which cannot be built into this

product, but must be supplied by the

operator.

SaVe tHeSe

InStructIonS.

GroundInG

to PreVent

electrIc SHock

and deatH From Incorrect

GroundInG WIre

connectIon:

Check with a qualified electrician

if you are in doubt as to whether

the outlet is properly grounded.

do not modify the power cord

plug provided with the

compressor. never remove the

grounding prong from the plug.

do not use the compressor if the

power cord or plug is damaged.

If damaged, have it repaired by a

service facility before use. If the

plug will not fit the outlet, have a

proper outlet installed by a

qualified electrician.

110-120 V~ Grounded compressors:

compressors with

three Prong Plugs

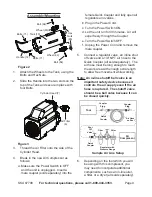

1. In the event of a malfunction or

breakdown, grounding provides a path

of least resistance for electric current to

reduce the risk of electric shock. This

compressor is equipped with an electric

cord having an equipment-grounding

conductor and a grounding plug. The

plug must be plugged into a matching

outlet that is properly installed and

grounded in accordance with all local

codes and ordinances.

2. Do not modify the plug provided – if it will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

3. Improper connection of the equipment-

grounding conductor can result in a risk

of electric shock. The conductor with

insulation having an outer surface that

is green with or without yellow stripes is

the equipment-grounding conductor. If

repair or replacement of the electric cord

or plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

4. Check with a qualified electrician or

service personnel if the grounding

instructions are not completely

understood, or if in doubt as to whether

the compressor is properly grounded.

5. Use only 3-wire extension cords that

have 3-prong grounding plugs and

3-pole receptacles that accept the

compressor’s plug.

6. Repair or replace damaged or worn cord

immediately.