7

ENG

The installation must conform to the require-

ments of the Authority having jurisdiction or,

in the absence of such requirement, to the

National Fuel Gas Code, ANSI Z223.1/NFPA 54

and, or CAN/CGAB149 Installation Code. Where

required by the Authority having jurisdiction, the

installation must conform to the Standard for

Controls and Safety Devices for Automatically

Fired Boilers, ANSI/ASME CSD-1. All boilers

must be installed with a proper pressure relief

valve. Pressure relief valves must be installed

to confirm to ANSI/ASME Boiler and Pressure

Vessel Code, Section IV, or CSA B51, as applicable.

If the boiler is installed above the radiation level,

or as required by the Authority having jurisdiction,

the installer must provide a low water cut-off

device at a time of installation. The boiler must be

installed in a fixed location and only by a qualified

installer, service agency or the gas supplier and is

familiar with the requirement that are contained

in this manual. Furthermore, the installation

must be in accordance with current standars

and regulations. The boiler must not be installed

on carpeting. The boiler when used in connection

with a refrigeration system, must be installed so

the chilled medium is piped in parallel with the boi-

ler with appropriate valves to prevent the chilled

medium from entering the boiler. The boiler piping

system of a hot water boiler connected to heating

coils located in air handling units where they may

be exposed to refrigerated air circulation must

be equipped with flow control valves or other

automatic means to prevent gravity circulation of

the boiler water during the cooling cycle. Service

instructions and recommended frequency gui-

delines periodic examination of venting systems

every six months. Venting systems, the vent-air

intake system, screens in the vent terminal

should be checked and cleaned every six months.

Low water cutoff should be checked and cleaned

every six months. Remove small cover retaining

screw and remove the cover. When the pump

is running and water is flowing around the boiler

, the actuator lifts off the micro switch. Check

that the operation of the actuator ; Ensure that

it is free and that it lifts and returns. If necessary

lubricate the pivot point of the actuator. Flue gas

passageways should be checked and cleaned

every six months. The burner should be checked

and cleaned every six months. Inspect the burner

and if necessary clean using a soft brush and a

vacuum cleaner, taking care not to damage the

front insulation. Check the ignition /ionisation

electrode, check the ignition spark gap (3.5 mm

+/- 0.5 mm) (0.138 in. +/- 0.02 in.). Before reas-

sembly inspect all seals and replace as required.

Furthermore, the installation must be in accor-

dance with current standards and regulations.

2.1

VENTILATION OF BOILER ROOM

When using air from the boiler room, an ade-

quate air supply shall by provided for combu-

stion of this boiler. An insufficient supply can

result in poor combustion and possible sooting

of the burner, combustion chamber or flue

passageway.

The boilers installed using inside air

supply must provide provisions for Combustion

Air and Ventilation Air in accordance with section

53, Air for Combustion and Ventilation, of the

National Flue Gas Code, ANSI Z 223,1/NFPA

54, or section 7,2, 7.3, or 7.4, of CAN/CGA B

149, Installation Codes, or local codes having

jurisdiction. Where an exhaust fan or any other

air consuming appliance is installed in the same

space as the boiler, sufficient air openings must

be available to provide fresh air when all appliance

are operating simultaneously. It is essential that

in rooms where the boiler are installed at least

as much air can arrive as required by normal

combustion of the gas consumed by the various

appliances. Consequently, it is necessary to make

openings in the walls for the air inlet into the

rooms. These openings must meet the following

requirements:

1. Have a total free section of a least 2225

mm

2

every kW (1 in

2

for every 1000 Btu/

hr) of heat input, with a minimum of 100

cm

2

(15.5 in

2

);

2. They must by located not more than 18 in

or less than 6 in above the floor level, not

prone to obstruction and protected by a

grid which does not reduce the effective

section required for the passage of air;

3. Where requide by jursdiction or when

required for additional opening must be

provided at the highest elevation practical.

With a hermetically sealed combustion chamber

and air supply circuit from outdoors, may be

installed in any room in the home. Keep boiler

area clear and free from combustible materials,

gasoline and other flammable vapors and liquids.

2.2 INSTALLATION

PLATE

The installation plate code 6246958 is supplied

with the boiler.

The optional installation plate code 8075416

is supplied with an instruction sheet for the

fixing.

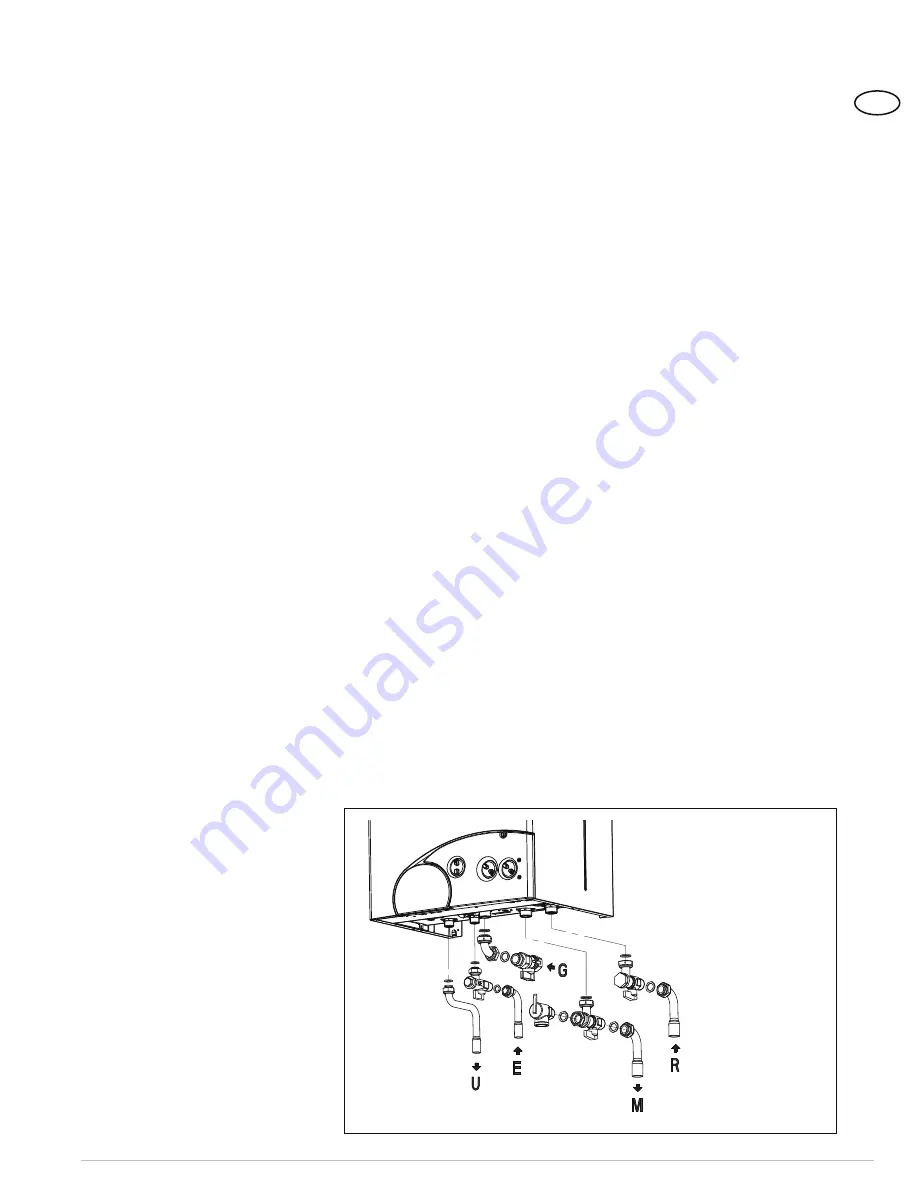

2.2.1 Isolating

valves

kit

To fit the isolating valves, supplied with the boiler,

use figure 4 for assembly.

2.2.2 System

connection

unions

The follow is available to facilitate water and gas

connection of the boiler with the heating system:

for assembly of the unions to see fig. 1.

2.3 CONNECTING

UP

SYSTEM

To protect the heat system from damaging cor-

rosion, flakes or deposits, before installation it is

extremely important to clean the system using

suitable products such as, descaler or slug re-

moving solution. For long-term protection against

corrosion and deposits, the use of inhibitors is re-

quired for new installations and after cleaning the

system. It is important to check the concentration

of the inhibitor after each system modification and

during maintenance following the manufacturer’s

instructions (specific tests are available at your

dealer). The safety valve drain must be connected

to a collection funnel to collect any discharge du-

ring interventions.

If the heating system is on a

higher floor than the boiler, install the on/off taps

supplied in kit on the heating system delivery/re-

turn pipes.

WARNING: Failure to clean the heat system or

add an adequate inhibitor invalidates the devi-

ce’s warranty.

2.3.1 Gas

Requirements

Read the date plate to be sure the water he-

ater is made for the type of gas being used.

An adhesive data plate is stuck inside the front

panel, it contains all the technical data iden-

tifying the boiler and the type of gas for which

the boiler is arranged. If the information does

not agree with the type of gas available, do not

install or operate the water heater. Call your

dealer. The gas piping must be installed accor-

ding to all local and state codes, or in absence

of local and state codes, with the latest “Natu-

ral gas and propane installation code”, CAN/

CSA-B 149.1 or “National Flue Gas Code”,

ANSI Z223.1 (NFPA 54). Consult the “Natural

gas and propane installation code” or “Natio-

nal Flue Gas Code” for the recommended gas

2 INSTALLATION

Figure 4

R C.H.

return

M C.H.

supply

G Gas connection

E D.H.W. inlet

U D.H.W.

outlet