25

SA5 OPERATIONS MANUAL & PARTS LIST

(Rev. 6/2020)

5.1 – DAILY MAINTENANCE

1. CHECK THE VACUUM/PRESSURE GAUGE TO SEE THAT IT IS OPERATING

AND READING CORRECTLY. TANK PRESSURE SHOULD NOT EXCEED

PRESSURES OF 7 PSI.

2. DEFECTIVE RELIEF VALVES SHOULD BE REPLACED IMMEDIATELY.

3. CHECK FOR GASKET LEAKS AND ANY TANK DAMAGE.

5.2 – WEEKLY MAINTENANCE

1. INSPECT TANK FOR SLUDGE BUILD UP. CLEAN TANK IF NECESSARY.

WITH SOME APPLICATIONS, THE TANK MAY NEED TO BE CLEANED MORE

FREQUENTLY. ALWAYS CLEAN THE TANK

BETWEEN PUMPING DIFFERENT TYPES OF FLUIDS

OR MATERIALS.

2. CLEAN AND INSPECT TANK FLOAT CONTROL. SEE

THAT THE FLOAT BALL SEALS AGAINST THE

GASKET. THE FLOAT CONTROL ASSEMBLY CAN BE

ASSESSED THROUGH THE POT OPENING IN THE

SUMP CLEANER.

3. CLEAN THE FILTER BAG BY RINSING IT OUT IN

LUKEWARM WATER.

4. OPERATE THE 8 PSI PRESSURE RELIEF HANDLE

TO MAKE SURE IT IS WORKING.

5.3 – MONTHLY MAINTENANCE

1. CHECK FOR WEAR ON POT LID WING NUTS AND STUDS.

2. INSPECT SUMP CLEANER HOSE.

3. GREASE THE SWIVEL CASTER AND WHEELS.

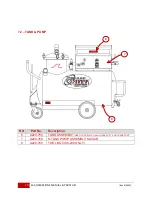

FLOAT

CONTROL