INTRODUCTION

Basic instructions

Machine safety

Before carrying out any service or repair work the machine

must be secured as follows:

Park the machine on a level and firm surface.

Lower the working attachment to the ground.

Lower the blade and the stabilizers to the ground.

Lock the upper structure.

Engage the parking brake.

Let the engine run at low idle for approximately

5 min

.

Stop the engine.

Set the starter switch key to position “0” and pull it out.

Move both hydraulic control levers in all directions, to re-

lease possible residual pressure inside the hydraulic sys-

tem.

Disconnect the pilot control.

Secure the machine with wheel chocks as to prevent its

rolling or overturning.

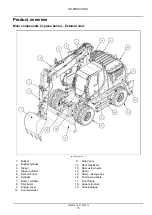

SMIL12WEX0021AA

1

Adjust the seat

A seat poorly adjusted for operator or work requirements

may quickly fatigue the operator leading to improper op-

erations.

The seat should be adjusted whenever machine operator

changes.

The operator should be able to press the pedals com-

pletely and to move the hydraulic control levers correctly,

with his back resting against the seat back.

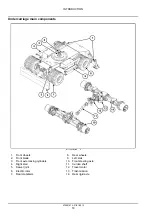

TULI12WEX2024AA

2

On machines equipped with seat belt:

• Check the seat belt condition. In the event of damage

or after an accident, have it replaced immediately.

• Fasten seat belt before starting to work.

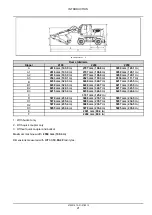

TULI12WEX2025AA

3

47500167A 31/01/2013

19