3 – ANhyDRoUS CoNfIGURATIoN – continued

3 – ANhyDRoUS CoNfIGURATIoN – continued

3.4 Nh

3

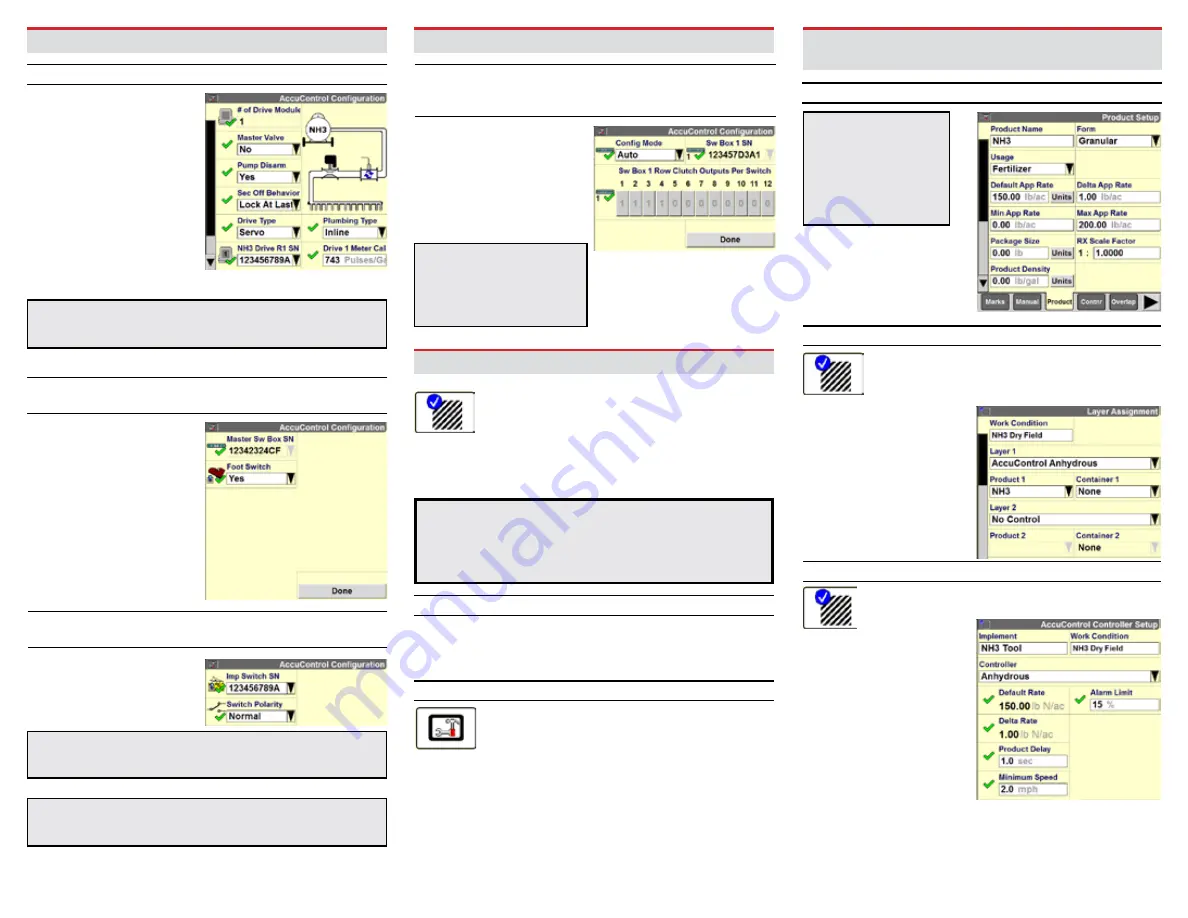

Drive Set-up

a) Select NH3 Drive [Yes]

b) Press ‘Setup’

c) Assign NH3 Drive Serial

Numbers (starting w/

modules on LH side)

d) Select Drive Type [Servo

or PWM]

e) Select Master Valve Type

f) Select Pump Disarm

fg) Select Sec Off Behavior

[Lock at Last or Turn Off]

h) Enter Drive Meter Cal

Number

(Pulses/Gal)

Note:

Pulses/gallon will be found on the liquid flow meter. Some

flow meters are measure in pulses/10 gallons. If this is the case,

divide that value by 10 to find pulses/gallon.

i) Press ‘Done’

3.5 Master Switch Box

(If Equipped with External Switch Box)

a) Select Master Sw Box [Yes]

b) Press ‘Setup’

c) Verify Serial Number of

Switch Box

d) Select Footswitch (if

installed)

e) Press “Done’

3.6 Implement Switch

(If equipped with Toolbar Mounted Implement Switch)

a) Select Imp Switch [Yes]

b) Press ‘Setup’

c) Select Imp Switch

Serial Number

d) Select Switch Polarity

Note:

Determine by raising and lowering the implement and

watch the Implement Status Arrow in Status/Warning Area for

proper operation.

e) Press ‘Done’

Note:

#1 EHR work switch on Magnum & Steiger tractors can be

used as an implement switch (the #1 EHR must be cycled once

after each start up to display the status arrow).

3.7 Section Switch Box (If equipped with

External Section Switch Box or Desire

Manual valve Section Control through Run Screens)

a) Select Section Switch Box

[Yes]

b) Press ‘Setup’

c) Select Config Mode [Auto]

or [Manual] for custom

d) Verify Sw Box Serial

Number (if equipped w/

external switchbox)

Note:

If no external switchbox

is installed, User Defined

Windows

can be assigned

to a Run Screen

(

Toolbox>layout

)

4 – WoRk CoNDITIoN – REQUIRED foR oPERATIoN

4 – WoRk CoNDITIoN – REQUIRED foR oPERATIoN

(continued)

Work Condition>layer

IMPoRTANT!

The settings below are linked to a

work condition. These must be selected or checked

whenever a work condition is created/changed: product type,

application rate, drive settings, product delay, product layer

control and product control.

NoTE!

A work condition name could be for a crop type, field

condition, or weather condition, etc.

NoTE!

This setup is required for logging/ mapping data and

using Overlap & Boundary Control.

4.1 Preparation

a) Insert a data card in the display

b) Create/select a Grower/Farm/Field/Task and Crop Type

(

Performance > Profile

)

4.2 Product Setup - continued

NoTE!

App Rate will not

be able to be adjusted

outside of this range

NoTE!

App Rates are

measured in pounds of

actual Nitrogen, NOT

pounds of NH

3

.

4.2 Product Setup

Toolbox> Product

a) Name the product (ex. NH3)

b) Select form type for product [Granular]

c) Select Usage [Fertilizer]

d) Enter Default Application Rate

e) Enter Minimum Application Rate & Maximum

Application Rate

4.3 Product layer Assignment

Work Condition> layer

Assign a product to a control section

of the Applicator.

a) Select/Create a

Work Condition

b) Select Layer 1 Control

Type [AccuControl

Anhydrous]

c) Select Product for

Layer 1 Control

d) Assign Additional Layers

as needed

4.4 Controller Setup – Anhydrous (if equipped)

Work Condition>Control

a) Verify Implement

b) Verify Work Condition

c) Select Controller

[Anhydrous]

d) Product Delay – Default

1.0 sec. (see section 7

for Product Delay

Measurement procedure)

e) Enter the Minimum

Speed (if ground speed

drops below this speed,

applicator will apply at

this set speed)

f) Enter value for Off-target

Alarm Limit