57

Use Fig. 72 and Table 25 to set the DIP switches for the desired

use of the sensor.

NOTE: When an S-Bus sensor is connected to an existing net-

work, it will take 60 minutes for the network to recognize and

auto-configure itself to use the new sensor.

During the 60-minute setup period, no alarms for sensor fail-

ures (except SAT) will be issued and no economizing function

will be available.

CO

2

Sensor Wiring

When using a CO

2

sensor, the black and brown common wires

are internally connected and only one is connected to “IAQ

COM” on the W7220. Use the power from the W7220 to pow-

er the CO

2

sensor OR make sure the ground for the power sup-

plies are common. See Fig. 73 for CO

2

sensor wiring.

Fig. 73 — CO

2

Sensor Wiring

INTERFACE OVERVIEW

This section describes how to use the EconoMi$er

®

user inter-

face for:

• Keypad and menu navigation

• Settings and parameter changes

• Menu structure and selection

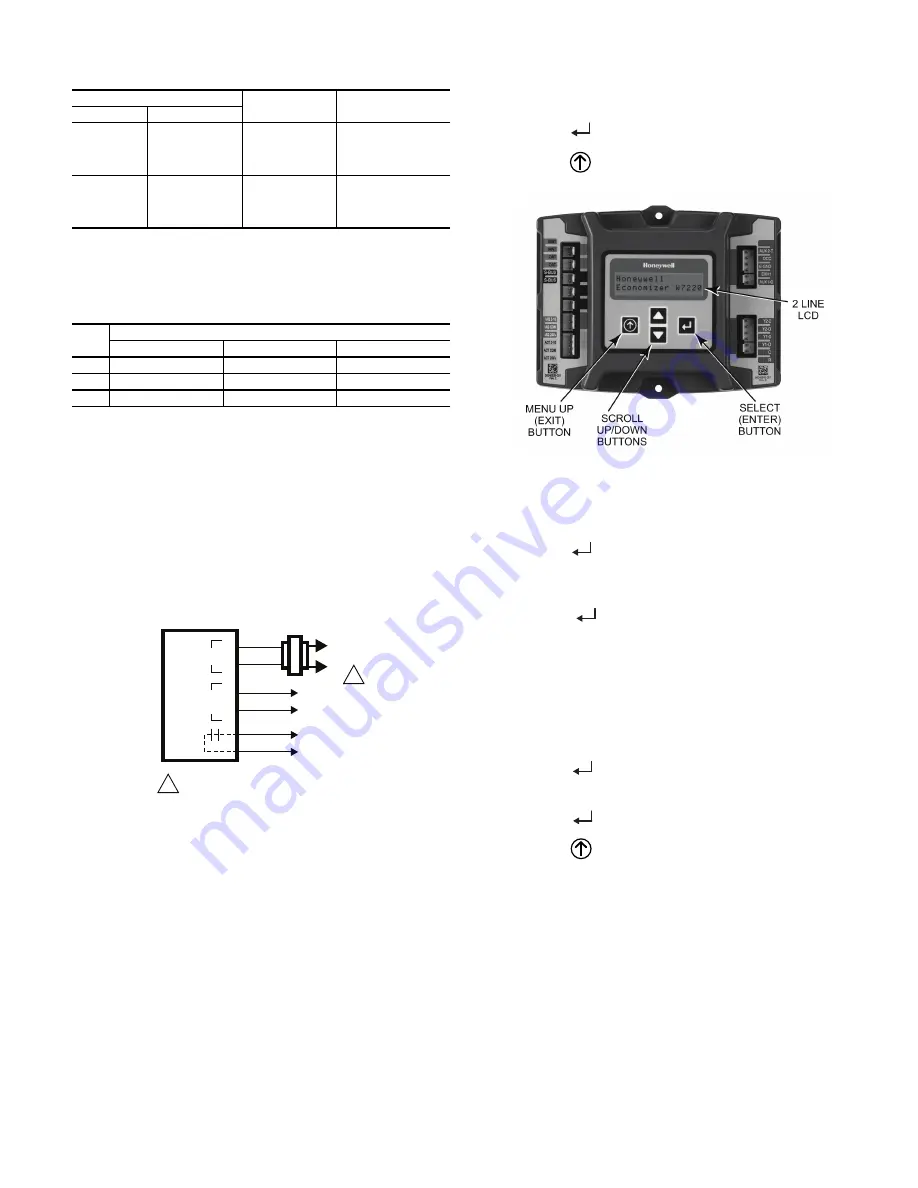

User Interface

The user interface consists of a 2-line LCD display and a 4-button

keypad on the front of the economizer controller.

Keypad

Use the four navigation buttons (see Fig. 74) to scroll through

the menus and menu items, select menu items, and to change

parameter and configuration settings.

To use the keypad when working with menus:

• Press the

▲

(Up arrow) button to move to the previous

menu.

• Press the

▼

(Down arrow) button to move to the next

menu.

• Press the

(Enter) button to display the first item in the

currently displayed menu.

• Press the

(Menu Up/Exit) button to exit a menu’s item

and return to the list of menus.

Fig. 74 — W7220 Controller Navigation Buttons

To use the keypad when working with Setpoints, System and

Advanced Settings, Checkout tests and Alarms:

1. Navigate to the desired menu.

2. Press the

(Enter) button to display the first item in the

currently displayed menu.

3. Use the

▲

and

▼

buttons to scroll to the desired

parameter.

4. Press the

(Enter) button to display the value of the

currently displayed item.

5. Press the

▲

button to increase (change) the displayed

parameter value.

6. Press the

▼

button to decrease (change) the displayed

parameter value.

NOTE: When values are displayed, pressing and holding the

▲

or

▼

button causes the display to automatically increment or

decrement.

1. Press the

(Enter) button to accept the displayed value

and store it in nonvolatile RAM. “CHANGE STORED”

displays.

2. Press the

(Enter) button to return to the current menu

parameter.

3. Press the

(Menu Up/Exit) button to return to the previ-

ous menu.

Menu Structure

Table 26 illustrates the complete hierarchy of menus and parame-

ters for the EconoMi$er

®

X system.

The Menus in display order are:

• STATUS

• SETPOINTS

• SYSTEM SETUP

• ADVANCED SETUP

• CHECKOUT

• ALARMS

NOTE: Some parameters in the menus use the letters MA or

MAT, indicating a mixed air temperature sensor location before

the cooling coil. This unit application has the control sensor

Table 24 — HH57AC081 Sensor Wiring Terminations

TERMINAL

TYPE

DESCRIPTION

NUMBER

LABEL

1

S-BUS

S-BUS

S-BUS

Communications

(Enthalpy Control

Sensor Bus)

2

S-BUS

S-BUS

S-BUS

Communications

(Enthalpy Control

Sensor Bus)

Table 25 — HH57AC081 Sensor DIP Switch

USE

DIP SWITCH POSITIONS FOR SWITCHES 1, 2, AND 3

1

2

3

DA

OFF

ON

OFF

RA

ON

OFF

OFF

OA

OFF

OFF

OFF

CO

2

SENSOR

24V

ANALOG

OUT

L1

(HOT)

L2

RED

BLACK

YELLOW

BROWN

ORANGE

GREEN

+

–

POWER SUPPLY. PROVIDE DISCONNECT

MEANS AND OVERLOAD PROTECTION

AS REQUIRED.

1

1

Summary of Contents for WeatherMaster Puron 48HC D17

Page 18: ...18 COOLING CHARGING CHARTS Fig 22 Cooling Charging Chart 15 Ton ...

Page 19: ...19 Fig 23 Cooling Charging Chart 17 5 Ton ...

Page 20: ...20 Fig 24 Cooling Charging Chart 20 Ton ...

Page 21: ...21 Fig 25 Cooling Charging Chart 25 Ton ...

Page 37: ...37 Fig 48 Unit Control Box IGC Location IGC Board IGC Board Side view Front view ...

Page 40: ...40 Fig 51 Typical IGC Wiring Diagram ...

Page 46: ...46 Fig 57 RTU Open Overlay for Economizer Wiring ...

Page 47: ...47 Fig 58 VFD Overlay for W2770 Controller Wiring ...

Page 84: ...84 Fig B 48HC D17 D28 Control Diagram 208 230 3 60 460 575 3 60 ...

Page 85: ...85 Fig C 48HC D17 D28 Power Diagram 208 230 3 60 ...

Page 86: ...86 Fig D 48HC D17 D28 Power Diagram 460 3 60 ...

Page 87: ...87 Fig E 48HC D17 D28 Power Diagram 575 3 60 ...

Page 88: ...88 Fig F 48HC D17 D28 Control Diagram with Humidi MiZer System ...

Page 89: ...89 Fig G 48HC D17 D28 Power Diagram 208 230 3 60 with Humidi MiZer System ...

Page 90: ...90 Fig H 48HC D17 D28 Power Diagram 460 3 60 with Humidi MiZer System ...

Page 91: ...91 Fig I 48HC D17 D28 Power Diagram 575 3 60 with Humidi MiZer System ...

Page 92: ...92 Fig J PremierLink System Control Wiring Diagram 50HE500891 F ...

Page 93: ...93 Fig K PremierLink System Control Wiring Diagram with Humidi MiZer System ...

Page 94: ...94 Fig L RTU OPEN Wiring Diagram ...

Page 95: ...95 Fig M RTU OPEN Wiring Diagram with Humidi MiZer System ...

Page 97: ......