21

Auxiliary (Electric) Heat Control

The 50HCQ unit can be equipped with one or two auxiliary elec-

tric heaters, to provide a second stage of heating. The DFB will

energize this Heating System for a Stage 2 Heating Command

(heaters operate concurrently with compressor(s) in the Stage 1

Heating cycle), for an Emergency Heating sequence (compressors

are off and only the electric heaters are energized) and also during

the Defrost cycle (to eliminate a “cold blow” condition in the

space).

Defrost

The defrost control mode is a time/temperature sequence. There

are two time components: The continuous run period and the test/

defrost cycle period. The temperature component is provided by

Defrost Thermostat 1 and 2 (DFT1 and DFT2) mounted on the

outdoor coil.

The continuous run period is a fixed time period between the end

of the last defrost cycle (or start of the current Heating cycle)

during which no defrost will be permitted. This period can be set

at 30, 60, 90, or 120 minutes by changing the positions of DIP

switches SW1 and SW2 (see Fig. 35 and Table 4). The default run

period is 30 minutes.

Shorting the jumpers for a period of 5 to 20 seconds bypasses the

remaining continuous run period and places the unit in a Forced

Defrost mode. If the controlling DFT is closed when this mode is

initiated, the unit will complete a normal defrost period that will

terminate when the controlling DFT opens or the 10 minute

defrost cycle limit is reached. If the controlling DFT is open when

this mode is initiated, the Defrost cycle will run for 30 seconds.

Both modes end at the end of the Defrost cycle.

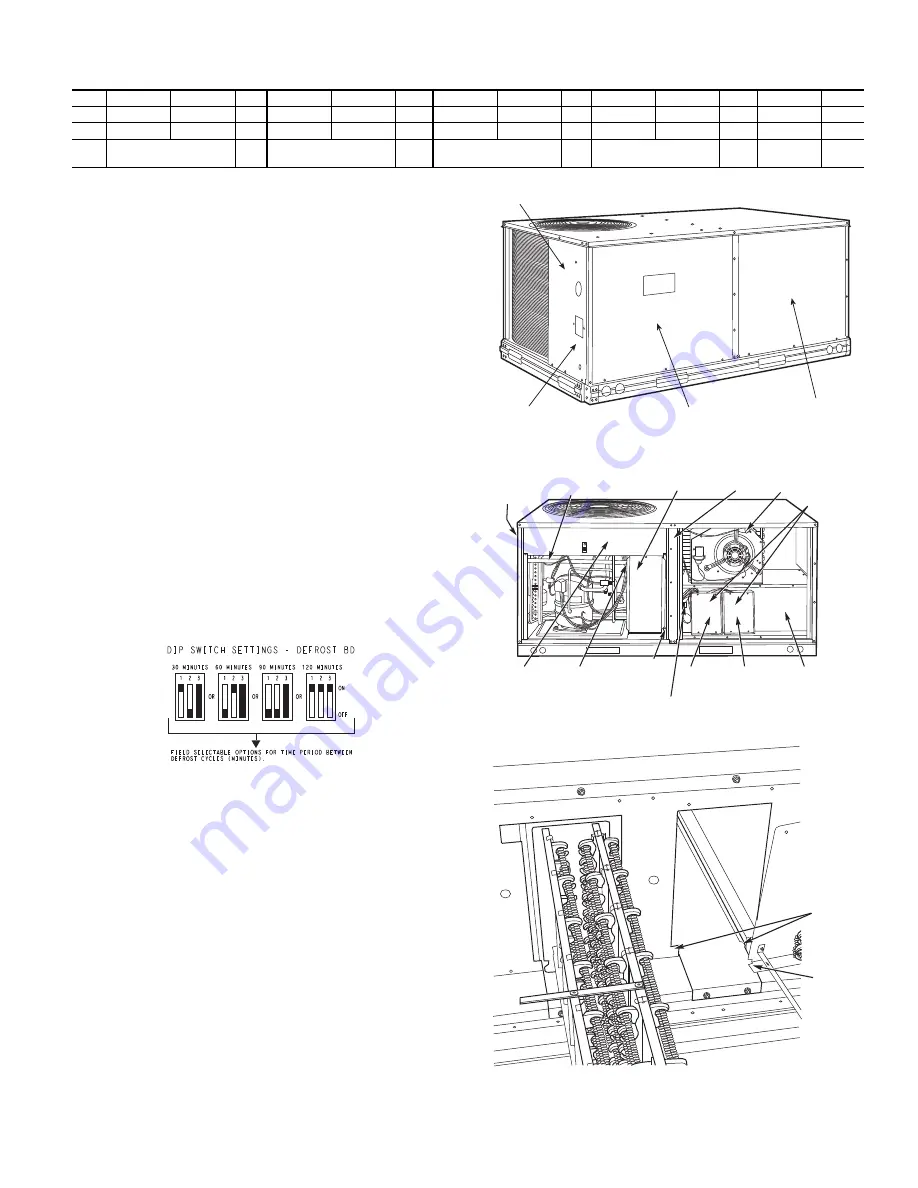

Fig. 35 — DIP Switch Settings - Defrost Board

ELECTRIC HEATERS

50HCQ units may be equipped with field-installed accessory elec-

tric heaters. The heaters are modular in design, with heater frames

holding open coil resistance wires strung through ceramic insula-

tors, line-break limit switches and a control contactor. One or two

heater modules may be used in a unit.

Heater modules are installed in the compartment below the indoor

(supply) fan outlet. Access is through the indoor access panel.

Heater modules slide into the compartment on tracks along the

bottom of the heater opening. See Fig. 36-38.

Not all available heater modules may be used in every unit. Use

only those heater modules that are UL listed for use in a specific

size unit. Refer to the label on the unit cabinet for the list of ap-

proved heaters.

Unit heaters are marked with Heater Model Numbers, but heaters

are ordered as and shipped in cartons marked with a correspond-

ing heater Sales Package part number.

NOTE: The value in position 9 of the part number differs between

the sales package part number (value is 1) and a bare heater model

number (value is 0).

Fig. 36 — Typical Access Panel Location (3-6 Ton)

Fig. 37 — Typical Component Location

Fig. 38 — Typical Module Installation

Table 4 — DIP Switch Positions

1

2

1

2

1

2

1

2

3

1

1

1

1

1

On

0

0

0

0

0

Off

30 minutes

(factory default)

60 minutes

90 minutes

120 minutes

Fan Delay

DISCONNECT MOUNTING

LOCATION

UNIT BLOCK-OFF

PANEL

OUTDOOR

ACCESS PANEL

INDOOR

ACCESS

PANEL

DISCONNECT

MOUNTING

LOCATION

EMT OR RIGID CONDUIT

(FIELD-SUPPLIED)

SINGLE

POINT BOX

CENTER

POST

HEATER

COVERS

HEATER

MOUNTING

BRACKET

HEATER

MODULE

(LOCATION 2)

HEATER

MODULE

(LOCATION 1)

SINGLE POINT

BOX

MOUNTING

SCREW

BRACKET AND

CONDUIT

DRIP BOOT

MAIN

CONTROL

BOX

CONTROL WIRE TERMINAL BLOCK

MANUAL RESET

LIMIT SWITCH

TRACK

FLANGE

Summary of Contents for WeatherMaster 50HCQ 04 Series

Page 4: ...4 Fig 2 50HCQ 04 06 Units Built On and After 4 15 2019 ...

Page 5: ...5 Fig 3 50HCQ 04 06 Units Built Prior to 4 15 2019 ...

Page 6: ...6 Fig 4 50HCQ 04 06 Corner Weights and Clearances ...

Page 7: ...7 Fig 5 50HCQ 04 06 Base Rail Details ...

Page 8: ...8 Fig 6 50HCQ 04 06 Thru the Base Charts ...

Page 23: ...23 Fig 41 Electro Mechanical Control Wiring 208 230v 460v ...

Page 24: ...24 Fig 42 Electro Mechanical Control Wiring 575v ...

Page 25: ...25 Fig 43 Electro Mechanical Power Wiring 208 230 1 60 ...

Page 26: ...26 Fig 44 Electro Mechanical Power Wiring 208 230 3 60 ...

Page 27: ...27 Fig 45 Electro Mechanical Power Wiring 460 3 60 ...

Page 28: ...28 Fig 46 Electro Mechanical Power Wiring 575 3 60 ...

Page 29: ...29 Fig 47 PremierLink Wiring Schematic 208 230 460v ...

Page 30: ...30 Fig 48 PremierLink Wiring Schematic 575v ...