27

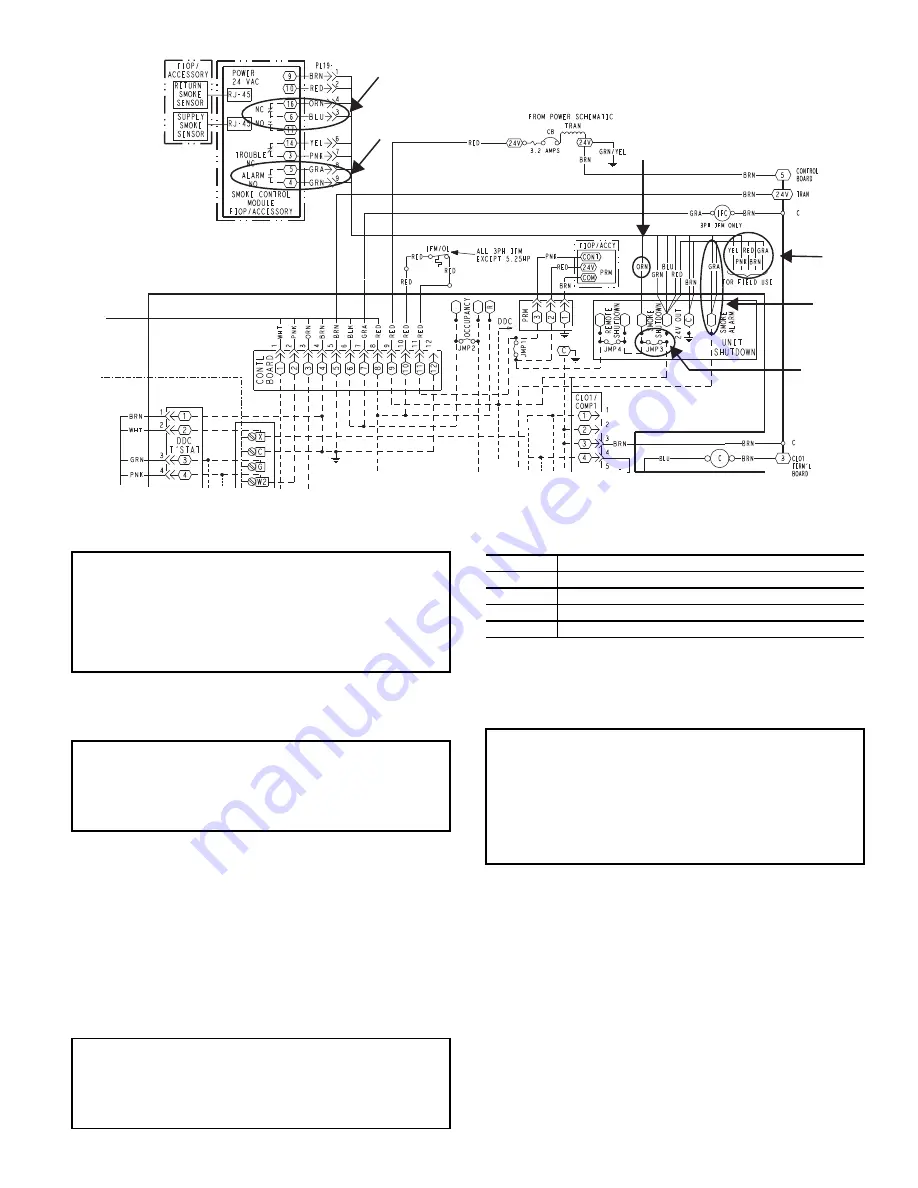

Fig. 56 — Typical Smoke Detector System Wiring

Dirty Controller Test

The dirty controller test checks the controller’s ability to initi-

ate a dirty sensor test and indicate its results.

DIRTY CONTROLLER TEST PROCEDURE

1. Press the controller’s test/reset switch for two seconds.

2. Verify that the controller’s Trouble LED flashes.

Dirty Sensor Test

The dirty sensor test provides an indication of the sensor’s abil-

ity to compensate for gradual environmental changes. A sensor

that can no longer compensate for environmental changes is

considered 100% dirty and requires cleaning or replacing. A

field provided SD-MAG test magnet must be used to initiate a

sensor dirty test. The sensor’s Dirty LED indicates the results

of the dirty test as shown in Table 7.

Table 7 — Dirty LED Test

DIRTY SENSOR TEST PROCEDURE

1. Hold the test magnet where indicated on the side of the

sensor housing for two seconds.

2. Verify that the sensor’s Dirty LED flashes.

Changing the Dirty Sensor Test

By default, sensor dirty test results are indicated by:

• The sensor’s Dirty LED flashing.

• The controller’s Trouble LED flashing.

• The controller’s supervision relay contacts toggle.

The operation of a sensor’s dirty test can be changed so that the

controller’s supervision relay is not used to indicate test results.

When two detectors are connected to a controller, sensor dirty

test operation on both sensors must be configured to operate in

the same manner.

TO CONFIGURE THE DIRTY SENSOR TEST OPERATION

1. Hold the test magnet where indicated on the side of the

sensor housing until the sensor’s Alarm LED turns on and

its Dirty LED flashes twice (approximately 60 seconds).

A

E

F

C

D

B

IMPORTANT: Failure to follow this ALERT can result

in an unnecessary evacuation of the facility.

This test places the duct detector into the alarm state.

Unless part of the test, disconnect all auxiliary equipment

from the controller before performing the test. If the duct

detector is connected to a fire alarm system, notify the

proper authorities before performing the test.

IMPORTANT: Failure to follow this ALERT can result in

an unnecessary evacuation of the facility.

Pressing the controller’s test/reset switch for longer than

seven seconds will put the duct detector into the alarm state

and activate all automatic alarm responses.

IMPORTANT: Failure to follow this ALERT can result in

an unnecessary evacuation of the facility.

Holding the test magnet against the sensor housing for more

than seven seconds will put the duct detector into the alarm

state and activate all automatic alarm responses.

FLASHES DESCRIPTION

1

0-25% dirty. (Typical of a newly installed detector)

2

25-50% dirty

3

51-75% dirty

4

76-99% dirty

IMPORTANT: Failure to follow this ALERT can result

in an unnecessary evacuation of the facility.

Changing the dirty sensor test operation will put the

detector into the alarm state and activate all automatic

alarm responses. Before changing dirty sensor test opera-

tion, disconnect all auxiliary equipment from the control-

ler and notify the proper authorities if connected to a fire

alarm system.

Summary of Contents for WeatherMaster 50HC04

Page 32: ...32 Fig 63 RTU Open Overlay for Economizer Wiring ...

Page 33: ...33 Fig 64 VFD Overlay for W2770 Controller Wiring ...

Page 86: ...86 Fig C 50HC A07 PAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Page 91: ...91 Fig H 50HC D12 PAC Control Diagram 208 230 3 60 460 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Page 93: ...93 Fig J 50HC A04 A06 PAC Power Diagram 208 230 1 60 APPENDIX D WIRING DIAGRAMS ...

Page 95: ...95 Fig L 50HC A07 PAC Power Diagram 208 230 3 60 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Page 100: ...100 Fig Q 50HC D11 PAC Power Diagram 208 230 3 60 APPENDIX D WIRING DIAGRAMS ...

Page 101: ...101 Fig R 50HC D11 PAC Power Diagram 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Page 103: ...103 Fig T 50HC D14 PAC Power Diagram 208 230 3 60 APPENDIX D WIRING DIAGRAMS ...

Page 104: ...104 Fig U 50HC D14 PAC Power Diagram 460 3 60 575 3 60 APPENDIX D WIRING DIAGRAMS ...

Page 124: ...124 Fig AO PremierLink System A04 A06 Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 125: ...125 Fig AP RTU Open System Control A04 A06 Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 126: ...126 Fig AQ PremierLink System A07 D14 Wiring Diagram APPENDIX D WIRING DIAGRAMS ...

Page 127: ...127 Fig AR RTU Open A07 D14 Wiring Diagram APPENDIX D WIRING DIAGRAMS ...