7

Pressing the

and

keys simultaneously

will scroll an expanded text description across the display indi-

cating the full meaning of each display point. Pressing

the

and

keys when the display is blank

will return the display to its default menu of rotating AUTO

VIEW display items. In addition, the password will need to be

entered again before changes can be made.

Changing item values or testing outputs is accomplished in the

same manner. Locate and display the desired item. If the dis-

play is in rotating auto-view, press the

key to stop the

display at the desired item. Press the

key again so

that the item value flashes. Use the arrow keys to change the

value or state of an item and press the

key to accept

it. Press the

key and the item, value or units display

will resume. Repeat the process as required for other items.

If the user needs to force a variable, follow the same process as

when editing a configuration parameter. When using the Navi-

gator display, a forced variable will be displayed with a blink-

ing “f” following its value. For example, if supply fan request-

ed (

FAN.F

) is forced, the display shows “YESf”, where the “f”

is blinking to signify a force on the point. Remove the force by

selecting the point that is forced with the

key and

then press the arrow keys simultaneously.

When using the scrolling marquee display, a forced variable is

displayed by a blinking “.” following its value.

Depending on the unit model, factory-installed options, and

field-installed accessories, some of the items in the various

mode categories may not apply.

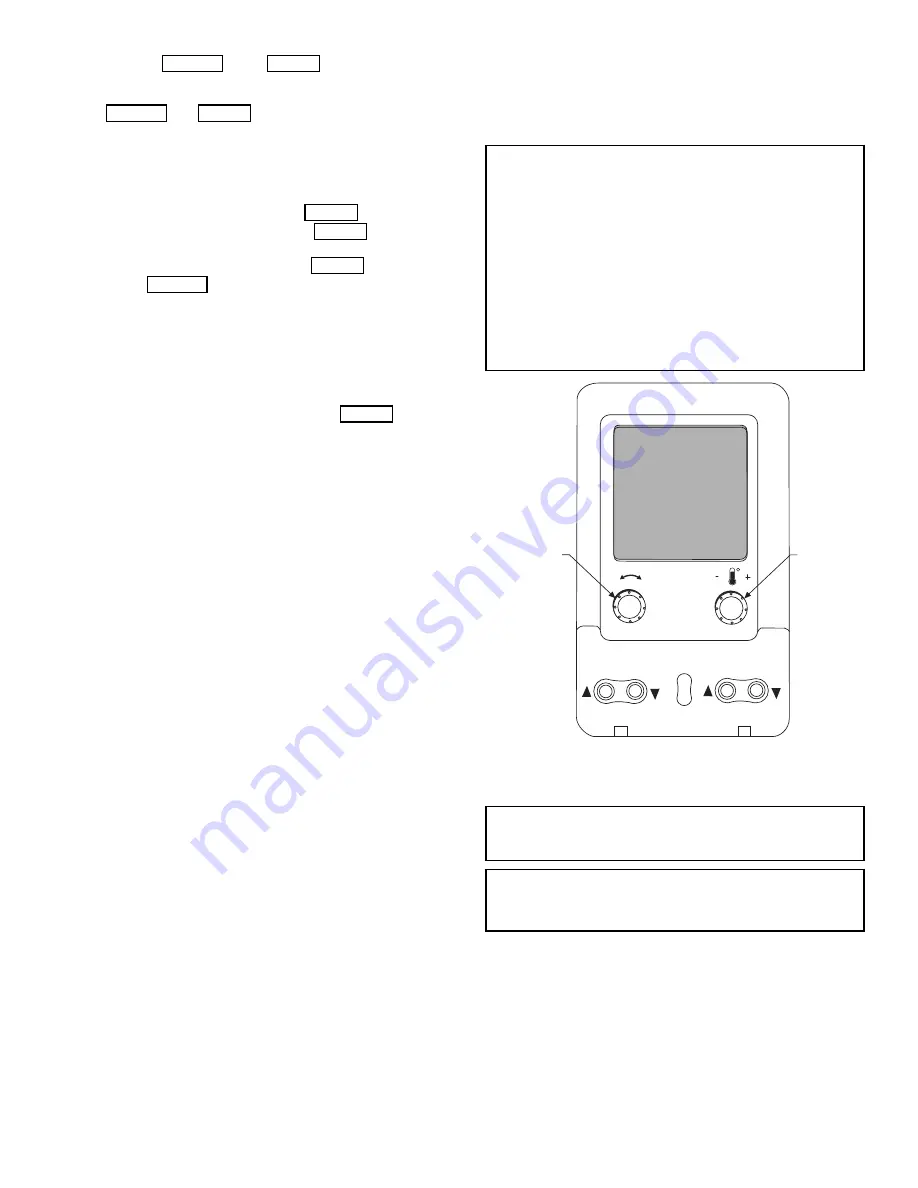

System Pilot™ Interface

The System Pilot interface (33PILOT-01) is a component of

the 3V™ system and can serve as a user-interface and configu-

ration tool for all Carrier communicating devices. The System

Pilot interface can be used to install and commission a 3V zon-

ing system, linkage compatible air source, universal controller,

and all other devices operating on the Carrier communicating

network.

Additionally, the System Pilot interface can serve as a wall-

mounted temperature sensor for space temperature measure-

ment. The occupant can use the System Pilot interface to

change set points. A security feature is provided to limit access

of features for unauthorized users. See Fig. 3 for System Pilot

interface details.

CCN Tables and Display

In addition to the unit-mounted scrolling marquee display, the

user can also access the same information through the CCN ta-

bles by using the System Pilot, Service Tool, or other CCN

programs. Details on the CCN tables are summarized in

Appendix B. The point names used for the CCN tables and the

scrolling marquee tables may be different and more items are

displayed in the CCN tables. As a reference, the CCN point

names are included in the scrolling marquee tables and the

scrolling marquee acronyms are included in the CCN tables in

Appendix B.

GENERIC STATUS DISPLAY TABLE

The GENERICS points table allows the servicer/installer the

ability to create a custom table in which up to 20 points from the

5 CCN categories (Status, Config/Service-Config, Set Point,

Maintenance, and Occupancy) may be collected and displayed.

In the Service-Config table section, there is a table named “Ge-

nerics.” This table contains placeholders for up to 20 CCN

point names and allows the user to decide which points are dis-

played in the GENERIC points table. Each one of these place-

holders allows the input of an 8-character ASCII string.

Using a CCN method of interface, go into the Edit mode for

the Service-Config table “Generics” and enter the CCN name

for each point to be displayed in the custom points table in the

order they will be displayed. When done entering point names,

download the table to the rooftop unit control.

Fig. 3 — System Pilot User Interface

START-UP

Unit Preparation

Check that unit has been installed in accordance with the in-

stallation instructions and applicable codes. Make sure that the

economizer hood has been installed and that the outdoor filters

are properly installed.

Internal Wiring

Ensure that all electrical connections in the control box are

tightened as required. If the unit has staged gas, modulating

gas, or SCR (silicon controlled rectifier) electric heat, make

sure that the LAT (leaving air temperature) sensors have been

routed to the supply ducts as required.

ESCAPE

ENTER

ESCAPE

ENTER

ENTER

ENTER

ENTER

ESCAPE

ENTER

IMPORTANT: The computer system software (Comfort-

VIEW™, Service Tool, etc.) that is used to interact with CCN

controls always saves a template of items it considers as static

(e.g., limits, units, forcibility, 24-character text strings, and point

names) after the software uploads the tables from a control.

Thereafter, the software is only concerned with run time data like

value and hardware/force status. With this in mind, it is import-

ant that any time a change is made to the Service-Config table

“Generics” (which in turn changes the points contained in the

GENERIC point table), a complete new upload be performed.

This requires that any previous table database be completely

removed first.

Failure to do this will prevent the user from dis-

playing the new points that have been created and the software

will have a different table database than the unit control.

IMPORTANT: Do not attempt to start unit, even momentar-

ily, until all items on the Start-Up Checklist (at the back of

this book) and the following steps have been completed.

IMPORTANT: The unit is shipped with the unit control dis-

abled. To enable the control, set Local Machine Disable

(

Service Test

STOP

) to No.

SCROLL

+

-

NAVIGATE/

EXIT

MODIFY/

SELECT

PAGE

Summary of Contents for Weathermaster 48P2030-100

Page 130: ...130 Fig 19 Typical Power Schematic Sizes 040 075 Shown ...

Page 131: ...131 Fig 20 Main Base Board Input Output Connections ...

Page 132: ...132 Fig 21 RXB EXB CEM SCB Input Output Connections ...

Page 133: ...133 Fig 22 Typical Gas Heat Unit Control Wiring 48P030 100 Units Shown ...

Page 134: ...134 Fig 23 Typical Electric Heat Wiring 50P030 100 Units Shown ...

Page 135: ...135 Fig 24 Typical Power Wiring 115 V ...

Page 136: ...136 Fig 25 Typical Gas Heat Section Size 030 050 Units Shown ...

Page 138: ...138 Fig 27 Component Arrangement Size 030 035 Units ...

Page 139: ...139 Fig 28 Component Arrangement Size 040 075 Units ...

Page 140: ...140 Fig 29 Component Arrangement Size 090 100 Units ...