50

VAV Cool Mode Selection during the Unoccupied Period

(C.TYP = 1,2; Operating Modes

MODE

OCC=OFF) and

Space Sensor Cool Mode Selection (C.TYP=4)

The machine control types that utilize this technique of mode

selection are:

•

C.TYP

= 1 (VAV-RAT) in the unoccupied period

•

C.TYP

= 2 (VAV-SPT) in the unoccupied period

•

C.TYP

= 4 (SPT-MULTI) in both the occupied and unoc

-

cupied period

These particular control types operate differently than the VAV

types in the occupied mode in that there is both a LOW COOL

and a HIGH COOL mode. For both of these modes, the control

offers 2 independent set points,

Setpoints

SA.LO

(for LOW

COOL mode) and

Setpoints

SA.HI

(for HIGH COOL mode).

The occupied and unoccupied cooling set points can be found

under

Setpoints

.

The heat/cool set point offsets are found under

Configura

-

tion

BP

D.LV.T

.

Operating modes are under

Operating Modes

MODE

.

Cool Mode Evaluation Logic

The first thing the control determines is whether the unit is in the

occupied mode (

OCC

) or is in the temperature compensated start

mode (

T.C.ST

). If the unit is occupied or in temperature compen

-

sated start mode, the occupied cooling set point (

OCSP

) is used.

For all other modes, the unoccupied cooling set point (

UCSP

) is

used. For further discussion and simplification, this will be re

-

ferred to as the “cooling set point.” See Fig. 5.

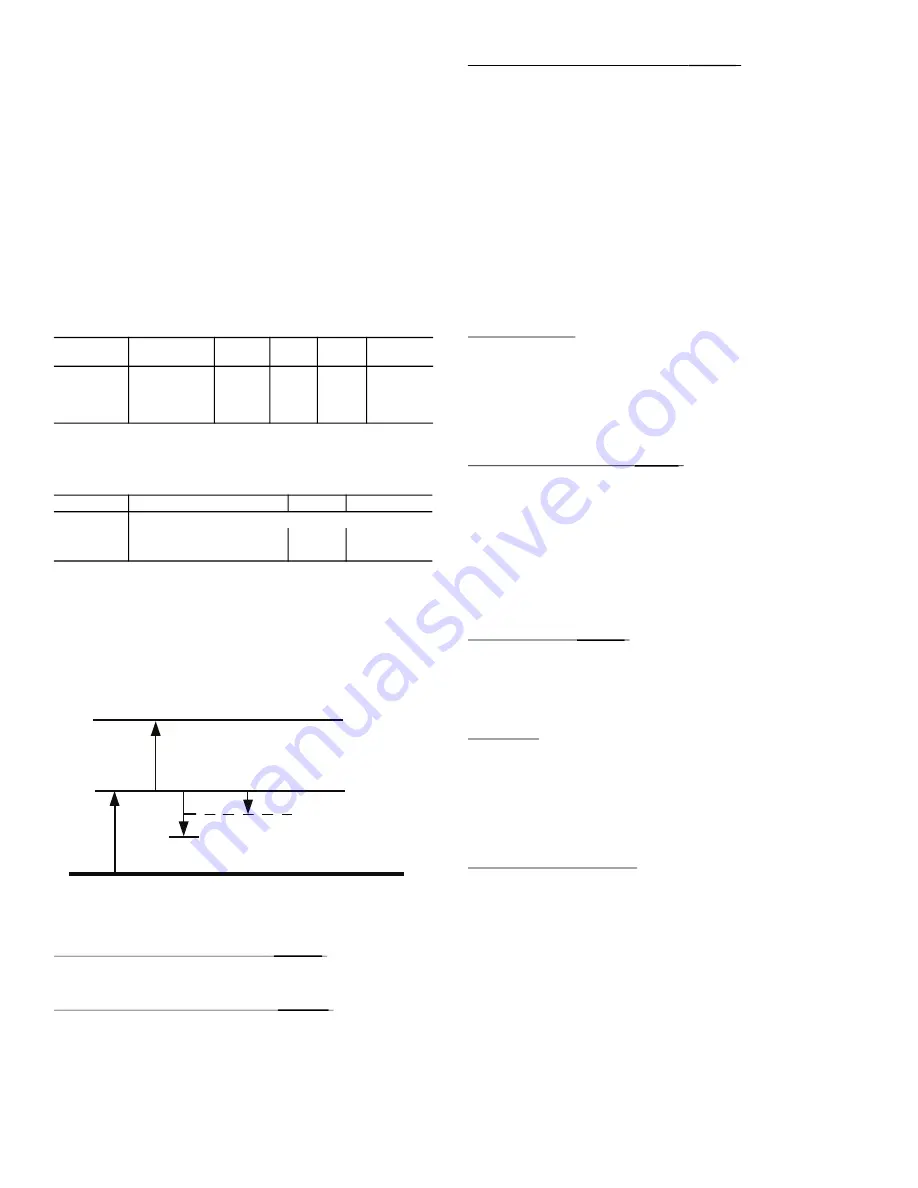

Fig. 5 —

Cool Mode Evaluation

Demand Level Low Cool On Offset

(

L.C.ON

)

This is the cooling set point offset added to the cooling set

point at which point a Low Cool mode starts.

Demand Level High Cool On Offset

(

H.C.ON

)

This is the cooling set point offset added to the “cooling set

point plus

L.C.ON

” at which point a High Cool mode begins.

Demand Level Low Cool Off Offset

(

L.C.OF

)

This is the cooling set point offset subtracted from “cooling set

point plus

L.C.ON

” at which point a Low Cool mode ends.

NOTE: The “high cool end” trip point uses the “low cool off”

(

L.C.OF

) offset divided by 2.

To enter into a LOW COOL mode, the controlling temperature

must rise above [the cooling set point plus

L.C.ON

.]

To enter into a HIGH COOL mode, the controlling temperature

must rise above [the cooling set point plus

L.C.ON

plus

H.C.ON

.]

To exit out of a LOW COOL mode, the controlling temperature

must fall below [the cooling set point plus

L.C.ON

minus

L.C.OF

.

]

To exit out of a HIGH COOL mode, the controlling tempera

-

ture must fall below [the cooling set point plus

L.C.ON

minus

L.C.OF

/2.]

Comfort Trending

In addition to the set points and offsets which determine the

trip points for bringing on and bringing off cool modes, there

are 2 configurations which work to hold off the transitioning

from a low cool to a high cool mode if the space is cooling

down quickly enough. This technique is referred to as comfort

trending, and the configurations of interest are

C.T.LV

and

C.T.TM

.

Cool Trend Demand Level

(

C.T.LV

)

This is the change in demand that must occur within the time

period specified by

C.T.TM

in order to hold off a HIGH COOL

mode, regardless of demand. This is not applicable to VAV

control types (

C.TYP

=1 and 2) in the occupied period. As long

as a LOW COOL mode is making progress in cooling the

space, the control will hold off on the HIGH COOL mode. This

is especially true for the space sensor machine control type

(

C.TYP

) = 4 because the unit may transition into the occupied

mode and see an immediate large cooling demand when the set

points change.

Cool Trend Time

(

C.T.TM

)

This is the time period upon which the cool trend demand level

(

C.T.LV

) operates and may hold off staging or a HIGH COOL

mode. This is not applicable to VAV control types (

C.TYP

=1

and 2) in the occupied period. See the Cool Trend Demand

Level section for more details.

Timeguards

In addition to the set points and offsets that determine the trip

points for bringing on and bringing off cool modes, there is a

timeguard that enforces a time delay between the transitioning

from a low cool to a high cool mode. This time delay is 8 min

-

utes. There is a timeguard which enforces a time delay between

the transitioning from a heat mode to a cool mode. This time

delay is 5 minutes.

Supply Air Set Point Control

Once the control has determined that a cooling mode is in effect,

the cooling control point (

Run Status

VIEW

CL.C.P

) is cal

-

culated and is based upon either

Setpoints

SA.HI

or

Set

-

points

SA.LO

, depending on whether a high or a low cooling

mode is in effect, respectively. In addition, if supply air reset is

configured, it will also be added to the cooling control point.

Refer to the SumZ Cooling Algorithm section for a discussion of

how the N Series

Comfort

Link controls manage supply-air tem

-

perature and the staging of compressors for these control types.

ITEM

EXPANSION RANGE UNITS

CCN

POINT DEFAULT

OCSP

Occupied

Cool Setpoint 55-80

dF

OCSP 75

UCSP

Unoccupied

Cool Setpoint 75-95

dF

UCSP 90

ITEM

EXPANSION

RANGE

CCN POINT

MODE

MODES CONTROLLING UNIT

OCC

Currently Occupied

Off/On

MODEOCCP

T.C.ST

Temp.Compensated Start

Off/On

MODETCST

H.C.ON

L.C. OF/2

L.C.ON

Cooling

S

etpoint (OC

S

P,UC

S

P)

L.C. OF

Lo Cool End

Hi Cool End

Lo Cool

S

t

a

rt

Hi Cool

S

t

a

rt

Summary of Contents for WeatherExpert 48N2

Page 135: ...135 Fig 18 48 50N Typical Power Schematic Nominal 075 Ton Unit Shown ...

Page 136: ...136 Fig 19 48 50N Typical Power Schematic Nominal Ton 90 150 Units Shown ...

Page 137: ...137 Fig 20 48 50N Main Base Board Input Output Connections ...

Page 138: ...138 Fig 21 48 50N RXB EXB CEM Input Output Connections a48 9307 ...

Page 139: ...139 Fig 22 48 50N EXV SCB Input Output Connections a48 9308 ...

Page 140: ...140 Fig 23 48N Typical Modulating Gas Heat Unit Control Wiring ...

Page 141: ...141 Fig 24 50N Typical Electric Heat Unit Control Wiring ...

Page 144: ...144 Fig 27 48N Typical Gas Heat Section Wiring Nominal Ton 120 to 150 Units ...

Page 145: ...145 Fig 28 48 50N Typical Power Component Control Wiring 460 v ...

Page 146: ...146 Fig 29 48 50N Component Control Wiring 575 v Nominal Ton 075 to 150 Units ...

Page 147: ...147 Fig 30 48 50N Component Arrangement Power Box ...

Page 148: ...148 Fig 31 48 50N Component Arrangement Control Box ...

Page 240: ...240 APPENDIX D VFD INFORMATION CONT Fig G VFD Bypass Wiring Diagram WHEN USED ...