92

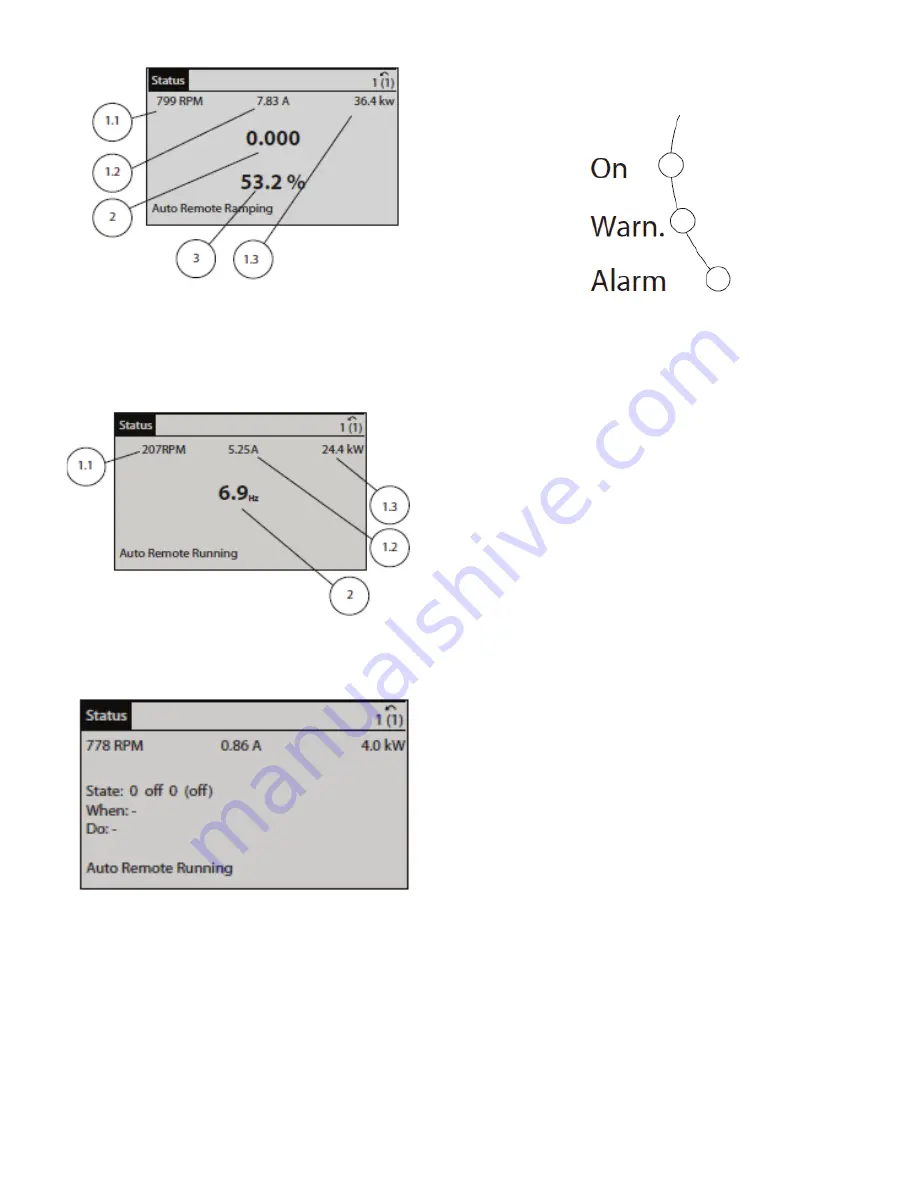

Fig. 84 — Status Display I

Status Display II shows the operating variables 1.1, 1.2, 1.3

and 2. In the example shown in Fig. 85, Speed, Motor Current,

Motor Power, and Frequency are selected as variables in the

first and second lines. Variables 1.1, 1.2, and 1.3 are shown in

small size. Variable 2 is shown in large size.

Fig. 85 — Status Display II

Status Display III shows events and actions of the Smart Logic

Control. Figure 86 shows an example.

Fig. 86 — Status Display III

The operator can adjust the display brightness by touching Sta-

tus and

▲

to darken the display or

▼

to lighten it.

Indicator lights (LEDs) indicate whether the unit is on and if

there are any warning or alarm conditions:

• Green LED (On): Control section is working. The On LED

is activated when the VFD receives power from mains

voltage, a DC bus terminal, or an external 24 V supply. At

the same time, the back light is on.

• Yellow LED (Warn.): Indicates a warning.

• Flashing Red LED (Alarm): Indicates an alarm.

The warning and/or alarm LEDs light up if certain threshold

values are exceeded. A status message and alarm text also ap-

pear on the control panel. See Fig. 87.

Fig. 87 — Indicator Lights

The menu keys below the display and indicator lights include

Status, Quick Menu, Main Menu, and Alarm Log. The Status

menu indicates the status of the frequency converter and/or the

motor. Three display modes are available (see Fig. 84-86). Use

the Status key for selecting mode of display or for changing

back to display mode from the Quick Menu Mode, the Main

Menu Mode, or the Alarm Log mode. The operator can also

use the Status key to toggle between single or double read-out

mode.

The Quick Menu key allows quick set-up of the frequency con-

verter. The most common HVAC functions can be programmed

here. Menu options include:

• My Personal Menu

• Quick Set-up

• Function Set-up

• Changes Made

• Loggings

The Function Set-up option provides quick and easy access to

all parameters required for most HVAC applications. Among

other features it also includes parameters for selecting which

variables to display on the local control panel, digital preset

speeds, scaling of analog references, closed loop single-zone

and multi-zone applications, and specific functions related to

fans, pumps and compressors.

The Quick Menu parameters can be accessed immediately un-

less a password has been created via 0-60 Main Menu Pass-

word, 0-61 Access to Main Menu without Password, 0-65 Per-

sonal Menu Password, or 0-66 Access to Personal Menu with-

out Password. It is possible to switch directly between Quick

Menu mode and Main Menu mode.

The Main Menu key is used for programming all parameters.

These can be accessed immediately unless a password has been

created via 0-60 Main Menu Password, 0-61 Access to Main

Menu without Password, 0-65 Personal Menu Password, or 0-

66 Access to Personal Menu without Password. For most

HVAC applications it is not necessary to access the Main Menu

parameters but instead use the Quick Menu. Quick Set-up and

Function Set-up provides the simplest and quickest access to

the typical required parameters.

It is possible to switch directly between Main Menu mode and

Quick Menu mode. The parameter shortcut can be carried out

by touching the Main Menu key for 3 seconds. The parameter

shortcut allows direct access to any parameter.

Touch Alarm Log to display a list of the 10 latest alarms (num-

bered A1-A10). To obtain additional details about an alarm,

touch the navigation keys to reach the alarm number and touch

OK. Information is displayed about the condition of the fre-

quency converter before it enters the alarm mode. The Alarm

Log key also provides access to a Maintenance log.

a30-5857

a30-5935

30 5859

a30-5856

Summary of Contents for AquaForce 30XV140

Page 79: ...79 Fig 76 VFD Communication Wiring Compressor A B Fan VFD A1 A2 B1 B2...

Page 228: ...228 Fig 90 30XV Typical Field Wiring Schematic cont...

Page 229: ...229 Fig 91 30XV Standard Tier 140 275 All Voltages Power Schematic NOTE See Legend on page 226...

Page 230: ...230 Fig 92 30XV Standard Tier 300 325 All Voltages Power Schematic NOTE See Legend on page 226...

Page 240: ...240 Fig 99 30XV Communication Wiring...

Page 241: ...241 Fig 100 30XV 115V Control Wiring All Tonnages All Voltages...

Page 242: ...242 Fig 101 30XV 24V Control Wiring 30XV140 325 All Voltages...

Page 243: ...243 Fig 101 30XV 24V Control Wiring 30XV140 325 All Voltages cont...

Page 244: ...244 Fig 102 30XV 24V Control Wiring 30XV350 500 All Voltages...

Page 245: ...245 Fig 102 30XV 24V Control Wiring 30XV350 500 All Voltages cont...

Page 246: ...246 Fig 103 Component Arrangement Diagram for 30XV140 325...

Page 247: ...247 Fig 103 Component Arrangement Diagram for 30XV140 325 cont...

Page 248: ...248 Fig 104 Component Arrangement Diagram for 30XV350 500...

Page 337: ...337 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig L System Information...

Page 338: ...338 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig M Unit and Language Settings...

Page 341: ...341 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig P Data Input 2...

Page 342: ...342 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig Q Data Input 3...

Page 347: ...347 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig U Pump Wiring Diagram...