46

Ice Storage Operation

Chiller operation can be configured to make and store ice. The en-

ergy management module and an Ice Done Switch are required for

operation in the Ice Mode. In this configuration, the machine can

operate with up to three cooling set points: Cooling Setpoint 1 is

used during the Occupied period, Cooling Setpoint 2 is used

during the Unoccupied period when the ice build is complete (Ice

Done Switch is closed), and Cooling Ice Setpoint is used during

the unoccupied period while ice is building (Ice Done Switch is

open). Refer to the 30XV Typical Field Wiring Schematic figure

on page 227 for Ice Done Switch wiring.

To configure this option with the Carrier Controller display:

Broadcast Configuration

The 30XV chiller with Greenspeed

®

Intelligence is capable of

broadcasting OAT, time, date, and holiday status to all elements in

the CCN system. In the stand-alone mode, broadcast must be acti-

vated to utilize holiday schedules and adjust for daylight saving

time. If the chiller is to be connected to a CCN system, determine

which system element is to be the network broadcaster and acti-

vate broadcast in all other system elements. Broadcast is activated

and deactivated in the Carrier Controller Broadcast Menu (

Main

Menu

Configuration Menu

Broadcast Menu

Brocasts

).

Only one element should be configured as a broadcaster. If a

broadcast is activated by a device that has been designated as a

network broadcaster, then broadcast time, date, and holiday status

will be updated over the CCN system. If broadcast is enabled, a

broadcast acknowledger must also be enabled. The acknowledger

cannot be the same machine as the broadcasting machine.

ACTIVATE

The Activate variable enables the broadcast function of the Carrier

Controller controls. If this variable is set to 0, this function is not

used and holiday schedules and daylight savings compensation are

not possible. Setting this variable to 1 allows the machine to

broadcast and receive broadcasts on the network. The following

information is broadcast: the time with compensation for daylight

savings, date, holiday flag, and the Outdoor Air Temperature.

Set this variable to 2 for stand-alone OAT broadcast. With this

configuration, daylight saving time and holiday determination

will be done without broadcasting through the bus.

To configure this option with the Carrier Controller display:

OAT BROADCAST

To enable the OAT broadcast, the unit broadcasting the tempera-

ture must be configured with its own CCN Bus and CCN Address.

Leaving the parameters at the factory default of 0 for the CCN Bus

and CCN Address disables the OAT Broadcast function. Once

configured, the first broadcast of OAT will be within 5 minutes.

To configure this option with the Carrier Controller display:

BROADCAST ACKNOWLEDGER

This configuration defines if the chiller will be used to ac-

knowledge broadcast messages on the CCN bus. One broadcast

acknowledger is required per bus, including secondary buses

created by the use of a bridge. The broadcast acknowledger

must be configured through the Network Service Tool.

Alarm Control

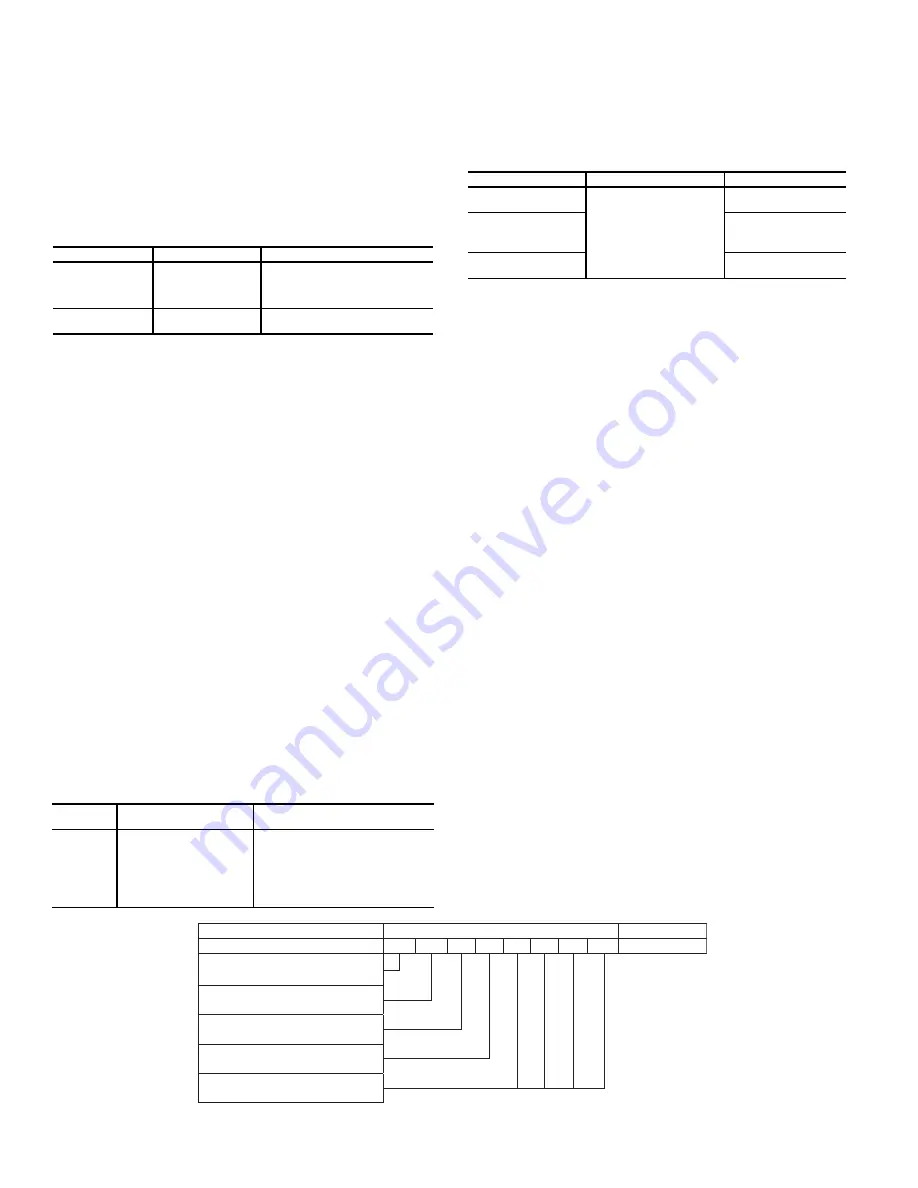

ALARM ROUTING CONTROL

Alarms recorded on the chiller can be routed through the CCN. To

configure this option, the Carrier Controller controls must be con-

figured to determine which CCN elements will receive and pro-

cess alarms. Input for the decision consists of eight digits, each of

which can be set to either 0 or 1. Setting a digit to 1 specifies that

alarms will be sent to the system element that corresponds to that

digit. Setting all digits to 0 disables alarm processing. The factory

default is 00000000. See Fig. 44. The default setting is based on

the assumption that the unit will not be connected to a network. If

the network does not contain a ComfortVIEW™, Comfort-

WORKS

™

, TeLink, DataLINK™, or BACLink module, enabling

this feature will only add unnecessary activity to the CCN com-

munication bus.

Typical configuration of the Alarm Routing variable is

11010000. This Alarm Routing status will transmit alarms to

ComfortVIEW

™

software, TeLink, BACLink, and DataLINK.

This option cannot be configured with the Carrier Controller

display. To change the alarm control routing through the Net-

work Service Tool, navigate to point

ALRM_CNT

in table

ALARMDEF

.

Fig. 44 — Alarm Routing Control

DISPLAY NAME

PATH

VALUE

Ice Mode

Enable

Main Menu

Configuration Menu

General Configura-

tion

Drop Down Selection (YES/NO)

Default = No

Cooling Ice

Setpoint

Main Menu

Setpoint Table

Default = 44°F (6.7°C)

Range = –20 to 78.8°F (–29 to 26°C)

DISPLAY

NAME

PATH

VALUE

Activate

Main Menu

Configuration Menu

Broadcast Menu

Brocasts

0 = Disabled

1 = Broadcast time, date, holiday

flag, and OAT

2 = OAT broadcast only (Daylight

savings time and holiday determina-

tion will be done without broadcast-

ing through the bus)

DISPLAY NAME

PATH

VALUE

Activate

Main Menu

Configuration Menu

Broadcast Menu

Brocasts

Range = 0 to 2

Default = 2

OAT Broadcast

Bus #

Range = 0 to 239

Default = 0

Element #

Range = 0 to 239

Default = 0

DE

S

CRIPTION

S

TATU

S

POINT

Al

a

rm Ro

u

ting

0 0 0 0 0 0 0 0 ALRM_CNT

ComfortVIEW™ or ComfortWORK

S

™

TeLink

Un

us

ed

BACLink or D

a

t

a

LINK™

Un

us

ed

Summary of Contents for AquaForce 30XV140

Page 79: ...79 Fig 76 VFD Communication Wiring Compressor A B Fan VFD A1 A2 B1 B2...

Page 228: ...228 Fig 90 30XV Typical Field Wiring Schematic cont...

Page 229: ...229 Fig 91 30XV Standard Tier 140 275 All Voltages Power Schematic NOTE See Legend on page 226...

Page 230: ...230 Fig 92 30XV Standard Tier 300 325 All Voltages Power Schematic NOTE See Legend on page 226...

Page 240: ...240 Fig 99 30XV Communication Wiring...

Page 241: ...241 Fig 100 30XV 115V Control Wiring All Tonnages All Voltages...

Page 242: ...242 Fig 101 30XV 24V Control Wiring 30XV140 325 All Voltages...

Page 243: ...243 Fig 101 30XV 24V Control Wiring 30XV140 325 All Voltages cont...

Page 244: ...244 Fig 102 30XV 24V Control Wiring 30XV350 500 All Voltages...

Page 245: ...245 Fig 102 30XV 24V Control Wiring 30XV350 500 All Voltages cont...

Page 246: ...246 Fig 103 Component Arrangement Diagram for 30XV140 325...

Page 247: ...247 Fig 103 Component Arrangement Diagram for 30XV140 325 cont...

Page 248: ...248 Fig 104 Component Arrangement Diagram for 30XV350 500...

Page 337: ...337 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig L System Information...

Page 338: ...338 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig M Unit and Language Settings...

Page 341: ...341 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig P Data Input 2...

Page 342: ...342 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig Q Data Input 3...

Page 347: ...347 APPENDIX J FACTORY SUPPLIED PUMPS cont Fig U Pump Wiring Diagram...