6

−

1

T-364

SECTION 6

SERVICE

NOTE

Use a refrigerant recovery system whenever

removing refrigerant. When working with refrig-

erants you must comply with all local govern-

ment environmental laws. In the U.S.A., refer to

EPA section 608.

WARNING

EXPLOSION HAZARD Failure to follow this

WARNING can result in death, serious

personal injury and / or property damage.

Never use air or gas mixtures containing

oxygen (O

2

) for leak testing or operating the

product.

Charge only with R

−

134a: Refrigerant must

conform to AHRI Standard 700

specification.

6.1 SECTION LAYOUT

Service procedures are provided in this section

beginning with refrigeration system service, then

refrigeration system component service, electrical

system service, temperature recorder service and

general service. Refer to the Table of Contents to locate

specific topics.

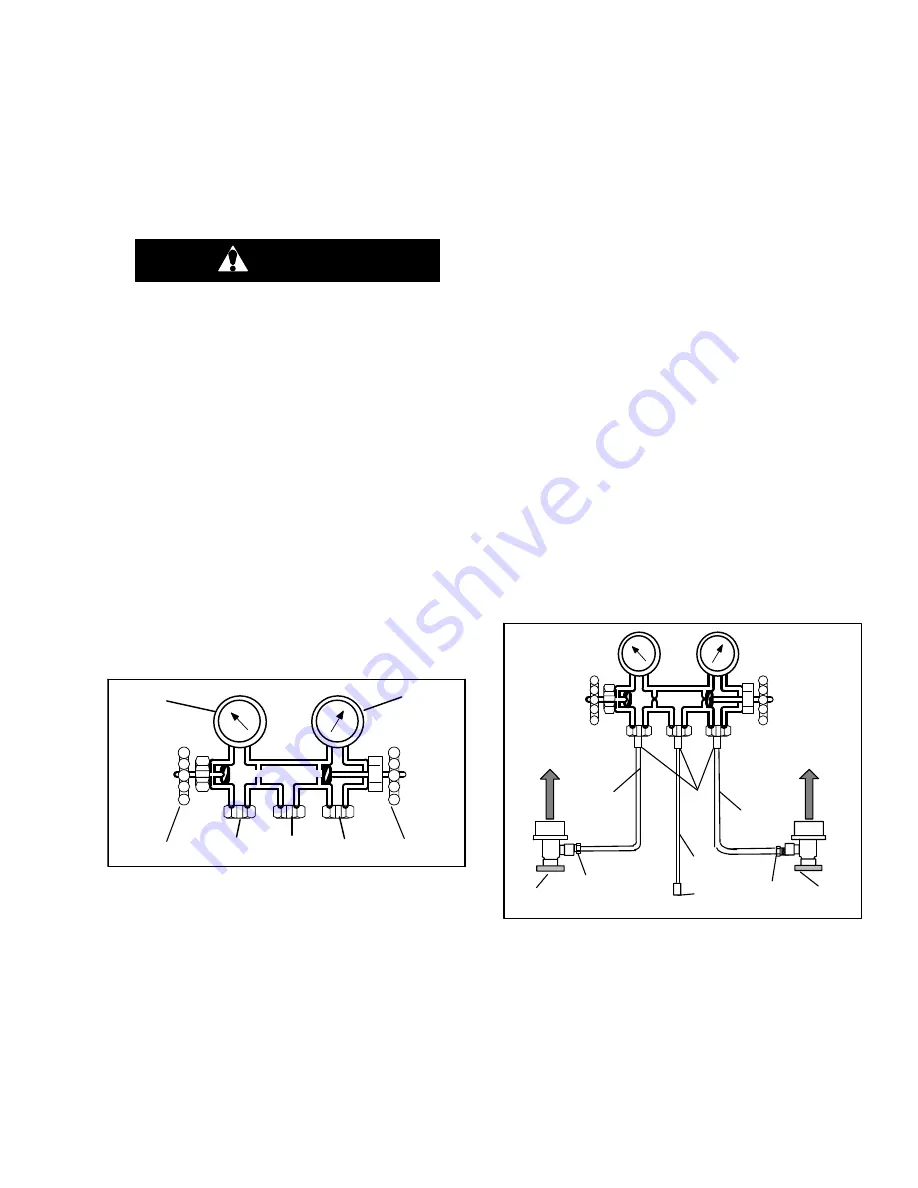

6.2 MANIFOLD GAUGE SET

The manifold gauge set (see Figure 6

1) is used to

determine system operating pressure, add refrigerant

charge, and to equalize or evacuate the system.

1. Suction Pressure Valve (shown backseated)

2. Suction Pressure Gauge

3. Discharge Pressure Gauge

4. Discharge Pressure Valve (shown frontseated)

5. High Side Connection

6. Utility Connection to:

a. Refrigerant cylinder

b. Vacuum Pump

c. Oil Container

7. Low Side Connection

Figure 6

−

1 Manifold Gauge Set

When the Suction Pressure Valve (1) is frontseated

(turned all the way in), the suction (low) pressure can be

checked at the Suction Pressure Gauge (2).

When the Discharge Pressure Valve (4) is frontseated,

the discharge (high) pressure can be checked at the

Discharge Pressure Gauge (3).

When both valves are backseated (all the way out), high

pressure vapor will flow into the low side.

When the Suction Pressure Valve (1) is open and the

Discharge Pressure Valve (4) shut, the system can be

charged through the Utility Connection (6). Oil can also

be added to the system.

A R-134a manifold gauge/hose set with self-sealing ho-

ses (see Figure 6

2) is required for service of the mod-

els covered within this manual. The manifold gauge/

hose set is available from Carrier Transicold. (Carrier

Transicold part number 07-00294-00, which includes

items 1 through 6, Figure 6

If the manifold gauge/hose set is new or was exposed to

the atmosphere, it will need to be evacuated to remove

contaminants and air as follows:

1. Backseat (turn counterclockwise) both field service

couplings (see Figure 6

2) and midseat both hand

valves.

2. Connect the yellow hose to a vacuum pump and re-

frigerant 134a cylinder.

3. Evacuate to 10 inches of vacuum and then charge

with R-134a to a slightly positive pressure of 0.1 kg/

cm

2

(1.0 psig).

4. Frontseat both manifold gauge set valves and dis-

connect from cylinder. The gauge set is now ready

for use.

Â

Â

ÂÂ

ÂÂ

Â

Â

To High Side

Access Valve

Â

To Low Side

Access Valve

1. RED Refrigeration and/or Evacuation Hose

(SAE J2196/R-134a)

2. Hose Fitting (0.5-16 Acme)

3. YELLOW Refrigeration and/or Evacuation Hose

(SAE J2196/R-134a)

4. Hose Fitting with O-ring (M14 x 1.5)

5. High Side Field Service Coupling (Red Knob)

6. BLUE Refrigeration and/or Evacuation Hose

(SAE J2196/R-134a)

7. Low Side Field Service Coupling (Blue Knob)

Figure 6

−

2 R-134a Manifold Gauge/Hose Set

Summary of Contents for 69NT40-561-201

Page 2: ......

Page 11: ......

Page 15: ......

Page 29: ......

Page 81: ......

Page 108: ...7 2 T 364 Based on Drawing 62 11753 Figure 7 2 SCHEMATIC DIAGRAM ...

Page 109: ...7 3 T 364 Based on Drawing 62 11753 Figure 7 3 UNIT WIRING DIAGRAM Sheet 1 of 2 ...

Page 110: ...7 4 T 364 Based on Drawing 62 11753 Figure 7 3 UNIT WIRING DIAGRAM Sheet 2 of 2 ...

Page 111: ......

Page 115: ......

Page 116: ......