15

The piping for the condensate drain and external trap can be com

-

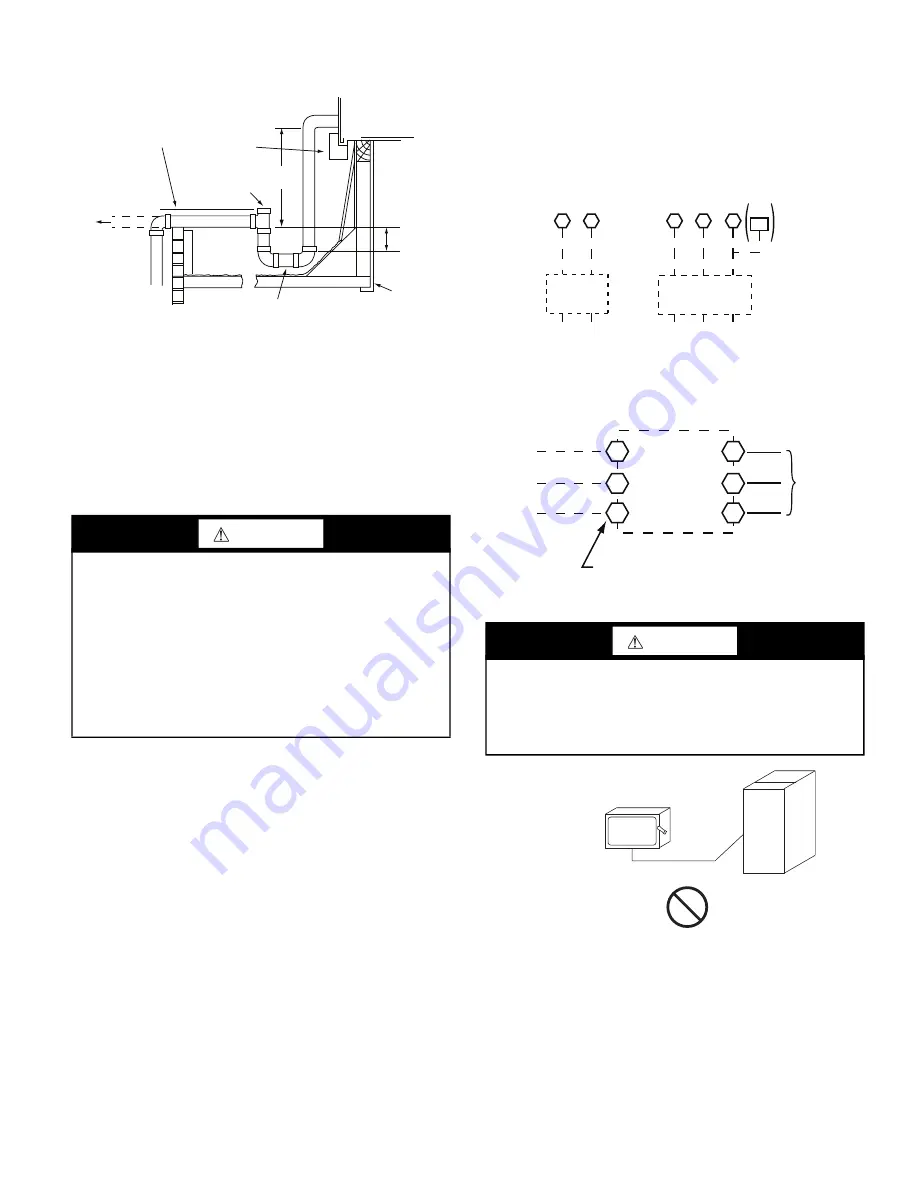

pleted after the unit is in place. See Fig. 20.

Fig. 20 — Condensate Drain Piping Details

All units must have an external trap for condensate drainage. In

-

stall a trap at least 4-in. (102 mm) deep and protect against

freeze-up. If drain line is installed downstream from the external

trap, pitch the line away from the unit at 1-in. per 10 ft (25 mm in

3 m) of run. Do not use a pipe size smaller than the unit connec

-

tion (

3

/

4

-in.).

Step 11 — Make Electrical Connections

NOTE: Field-supplied wiring shall conform with the limitations

of minimum 63°F (33°C) rise.

FIELD POWER SUPPLY

If equipped with optional Powered Convenience Outlet: The pow

-

er source leads to the convenience outlet’s transformer primary are

not factory-connected. Installer must connect these leads accord

-

ing to required operation of the convenience outlet. If an always-

energized convenience outlet operation is desired, connect the

source leads to the line side of the unit-mounted disconnect.

(Check with local codes to ensure this method is acceptable in

your area.) If a de-energize via unit disconnect switch operation of

the convenience outlet is desired, connect the source leads to the

load side of the unit disconnect. On a unit without a unit-mounted

disconnect, connect the source leads to compressor contactor C

and indoor fan terminal block (IFTB) pressure lugs with unit field

power leads.

Refer to Fig. 27 for power transformer connections and the dis

-

cussion on connecting the convenience outlet on page 16. Field

power wires are connected to the unit at line-side pressure lugs

on compressor contactor C and indoor fan contactor IFC (see

wiring diagram label for control box component arrangement) or

at factory-installed option non-fused disconnect switch. Max

wire size is #2 AWG (copper only, see Fig. 22). See Fig. 21 and

unit label diagram for field power wiring connections.

NOTE: TEST LEADS — Unit may be equipped with short leads

(pigtails) on the field line connection points on contactor C or op

-

tional disconnect switch. These leads are for factory run-test pur

-

poses only; remove and discard before connecting field power

wires to unit connection points. Make field power connections di

-

rectly to line connection pressure lugs only.

Fig. 21 — Power Wiring Connections

Fig. 22 — Disconnect Switch and Unit

UNITS WITH FACTORY-INSTALLED NON-FUSED DIS

-

CONNECT

The factory-installed option non-fused disconnect (NFD) switch is

located in a weatherproof enclosure located under the main con

-

trol box. The manual switch handle and shaft are shipped in the

disconnect enclosure. Assemble the shaft and handle to the switch

at this point. Discard the factory test leads (see Fig. 21).

Connect field power supply conductors to LINE side terminals

when the switch enclosure cover is removed to attach the handle.

WARNING

ELECTRIC SHOCK HAZARD

Failure to follow this warning could result in personal injury or

death.

Unit cabinet must have an uninterrupted, unbroken electrical

ground to minimize the possibility of personal injury if an

electrical fault should occur. This ground may consist of elec

-

trical wire connected to unit ground lug in control compart

-

ment, or conduit approved for electrical ground when installed

in accordance with NEC; ANSI/NFPA 70, latest edition (in

Canada, Canadian Electrical Code CSA [Canadian Standards

Association] C22.1), and local electrical codes.

NOTE: Trap should be deep enough to offset maximum unit static

difference. A 4-in. (102 mm) trap is recommended.

MINIMUM PITCH

1˝ (25 mm) PER

1

0´

(

3

m) OF LINE

BA

S

E RAIL

OPEN

VENT

TO ROOF

DRAIN

DRAIN PLUG

ROOF

CURB

S

EE NOTE

3

˝ (76 mm)

MIN

WARNING

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, or property damage.

Do not connect aluminum wire between disconnect switch and

unit. Use only copper wire.

Disconnect

per

NEC

Disconnect

per

NEC

20

8

/2

3

0-1-60

11

1

3

11

1

3

1

3

L1

L2

L

3

TB

C

C

IFC

or

(1-ph

IFM)

20

8

/2

3

0-

3

-60

460-

3

-60

575-

3

-60

Units Without Non-Fused Disconnect Option

Units With Non-Fused Disconnect Option

2

4

6

1

3

5

L1

L2

L

3

Optional

Disconnect

S

witch

Disconnect factory test leads; discard.

Factory

Wiring

COPPER

WIRE ONLY

ELECTRIC

DI

S

CONNECT

S

WITCH

ALUMINUM

WIRE

Summary of Contents for 50KC04

Page 4: ...4 Fig 2 Unit Dimensional Drawing of Units Built On and After 4 15 19...

Page 5: ...5 Fig 3 Unit Dimensional Drawing of Units Built on and Prior to 4 15 19...

Page 6: ...6 Fig 4 Unit Corner Weights and Clearances...

Page 7: ...7 Fig 5 Base Rail Details...

Page 8: ...8 Fig 6 Thru the Base Charts...

Page 35: ...35 Fig 49 Electro Mechanical Control Wiring Diagram...

Page 36: ...36 Fig 50 Electro Mechanical Control Wiring Diagram with Humidi MiZer System...

Page 37: ...37 Fig 51 Electro Mechanical Power Wiring...

Page 38: ...38 Fig 52 PremierLink Wiring Schematic...

Page 39: ...39 Fig 53 PremierLink Wiring Schematic with Humidi MiZer System...

Page 40: ...40 Fig 54 RTU Open System Control Wiring Diagram...

Page 41: ...41 Fig 55 RTU Open System Control Wiring Diagram with Humidi MiZer System...

Page 47: ...47 Fig 63 TXV Metering Device Position in Reheat Coil Typical Diagram for Sizes 04 06 TXV...

Page 48: ......

Page 49: ......