33

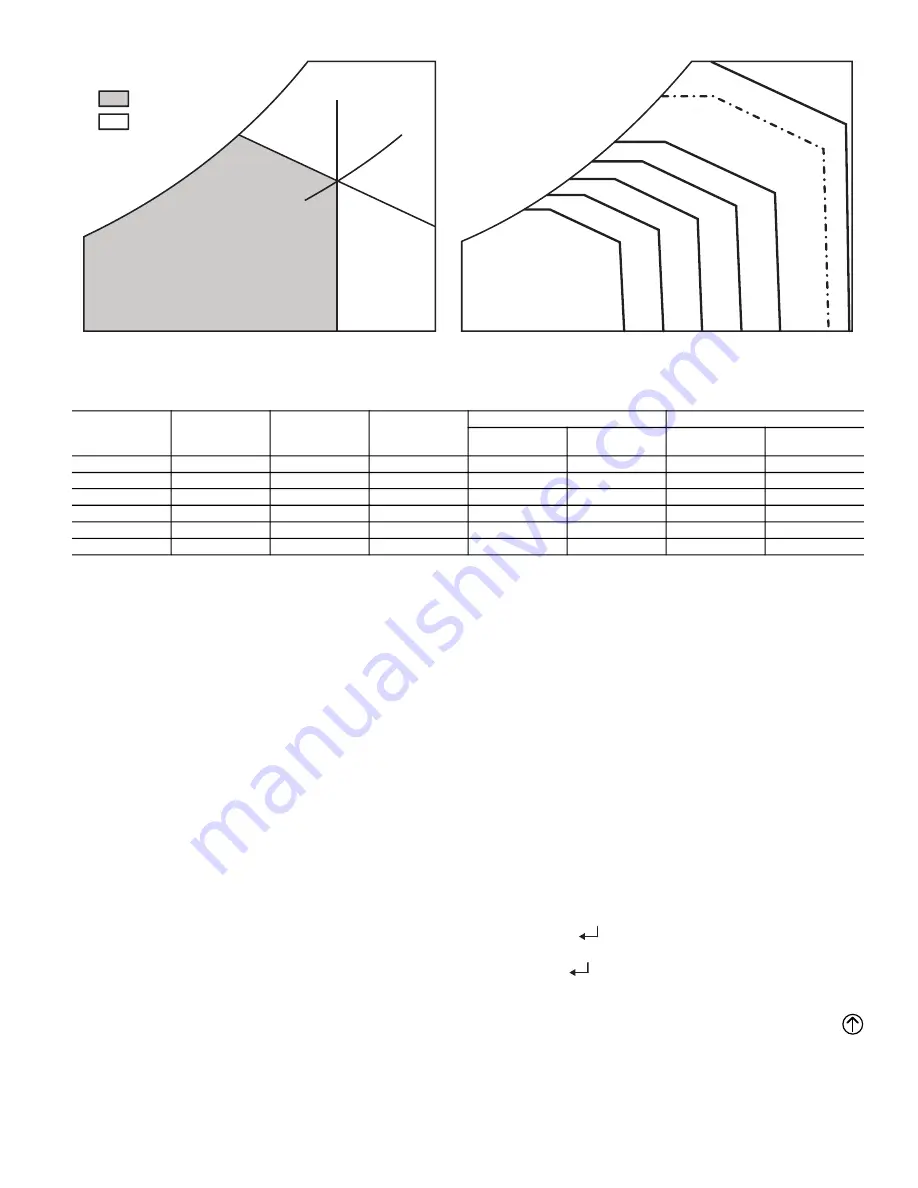

Fig. 48 — Single Enthalpy Curve Boundaries

ENTHALPY SETTINGS

When the OA temperature, enthalpy and dew point are below the

respective set points, the Outdoor Air can be used for economiz

-

ing. Figure 48 shows the new single enthalpy boundaries in the

W7220. There are 5 boundaries (set points ES1 through ES5),

which are defined by dry bulb temperature, enthalpy and dew

point.

Refer to Table 13 for ENTH CURVE set point values.

The W7220 calculates the enthalpy and dew point using the OA

temperature and humidity input from the OA enthalpy sensor.

When the OA temperature, OA humidity and OA dew point are

all below the selected boundary, the economizer sets the econo

-

mizing mode to YES, economizing is available.

When all of the OA conditions are above the selected boundary,

the conditions are not good to economize and the mode is set to

NO.

Figure 48 shows the 5 current boundaries. There is also a high lim

-

it boundary for differential enthalpy. The high limit boundary is

ES1 when there are no stages of mechanical cooling energized and

HL (high limit) when a compressor stage is energized.

CHECKOUT

Inspect all wiring connections at the economizer module’s termi

-

nals, and verify compliance with the installation wiring diagrams.

For checkout, review the Status of each configured parameter and

perform the Checkout tests.

NOTE: For information about menu navigation and use of the

keypad see Interface Overview on page 25.

Power Up

After the W7220 module is mounted and wired, apply power.

Initial Menu Display

On initial start up, Honeywell displays on the first line and econo

-

mizer W7220 on the second line. After a brief pause, the revision

of the software appears on the first line and the second line will be

blank.

Power Loss (Outage or Brownout)

All set points and advanced settings are restored after any power

loss or interruption.

NOTE: All settings are stored in non-volatile flash memory.

Status

Use the Status menu (see Table 7) to check the parameter values

for the various devices and sensors configured.

NOTE: For information about menu navigation and use of the

keypad, see Interface Overview on page 25.

Checkout Tests

Use the Checkout menu (see page 30) to test the damper operation

and any configured outputs. Only items that are configured are

shown in the Checkout menu.

NOTE: For information about menu navigation and use of the

keypad, see Interface Overview on page 25.

To perform a Checkout test:

1. Scroll to the desired test in the Checkout menu using the ▲

and ▼ buttons.

2. Press the

(Enter) button to select the item. RUN?

appears.

3. Press the

(Enter) button to start the test. The unit pauses

and then displays IN PROGRESS. When the test is complete,

DONE appears.

4. When all desired parameters have been tested, press the

(Menu Up) button to end the test.

The Checkout tests can all be performed at the time of installation

or at any time during the operation of the system as a test that the

system is operable.

ECONOMIZING

AVAILABLE

NOT AVAILABLE

ENTHALPY

RA

HUM (%RH)

RA

TEMP

TEMPERATURE

ABSOLUTE HUMIDITY

ES5

ES4

ES3

ES2

ES1

HL

P1

(T,RH)

P2 (T,RH)

SINGLE ENTHALPY

DUAL ENTHALPY

HIGH LIMIT

Table 13 — Single Enthalpy and Dual Enthalpy High Limit Curves

ENTHALPY

CURVE

TEMP. DRY

BULB (F)

TEMP.

DEWPOINT (F)

ENTHALPY

(btu/lb/da)

POINT P1

POINT P2

TEMP. (F)

HUMIDITY

(%RH)

TEMP. (F)

HUMIDITY

(%RH)

ES1

80

60

28.0

80

36.8

66.3

80.1

ES2

75

57

26.0

75

39.6

63.3

80.0

ES3

70

54

24.0

70

42.3

59.7

81.4

ES4

65

51

22.0

65

44.8

55.7

84.2

ES5

60

48

20.0

60

46.9

51.3

88.5

HL

86

66

32.4

86

38.9

72.4

80.3

Summary of Contents for 50KC04

Page 4: ...4 Fig 2 Unit Dimensional Drawing of Units Built On and After 4 15 19...

Page 5: ...5 Fig 3 Unit Dimensional Drawing of Units Built on and Prior to 4 15 19...

Page 6: ...6 Fig 4 Unit Corner Weights and Clearances...

Page 7: ...7 Fig 5 Base Rail Details...

Page 8: ...8 Fig 6 Thru the Base Charts...

Page 35: ...35 Fig 49 Electro Mechanical Control Wiring Diagram...

Page 36: ...36 Fig 50 Electro Mechanical Control Wiring Diagram with Humidi MiZer System...

Page 37: ...37 Fig 51 Electro Mechanical Power Wiring...

Page 38: ...38 Fig 52 PremierLink Wiring Schematic...

Page 39: ...39 Fig 53 PremierLink Wiring Schematic with Humidi MiZer System...

Page 40: ...40 Fig 54 RTU Open System Control Wiring Diagram...

Page 41: ...41 Fig 55 RTU Open System Control Wiring Diagram with Humidi MiZer System...

Page 47: ...47 Fig 63 TXV Metering Device Position in Reheat Coil Typical Diagram for Sizes 04 06 TXV...

Page 48: ......

Page 49: ......