121

APPENDIX C — VARIABLE FREQUENCY DRIVE (VFD)

On units equipped with supply fan VFDs, the indoor fan motor is

controlled by a 3-phase VFD. The supply fan VFD is located in

the supply fan section behind the access door. These units use

ABB VFDs. The VFD varies the frequency of the AC voltage

supplied to the indoor fan. This allows the variance in the speed of

the fan. The VFD is always powered during normal operation and

the fan is stopped by driving the speed to 0. Fig. A and Table P

show the VFD terminals and connections.

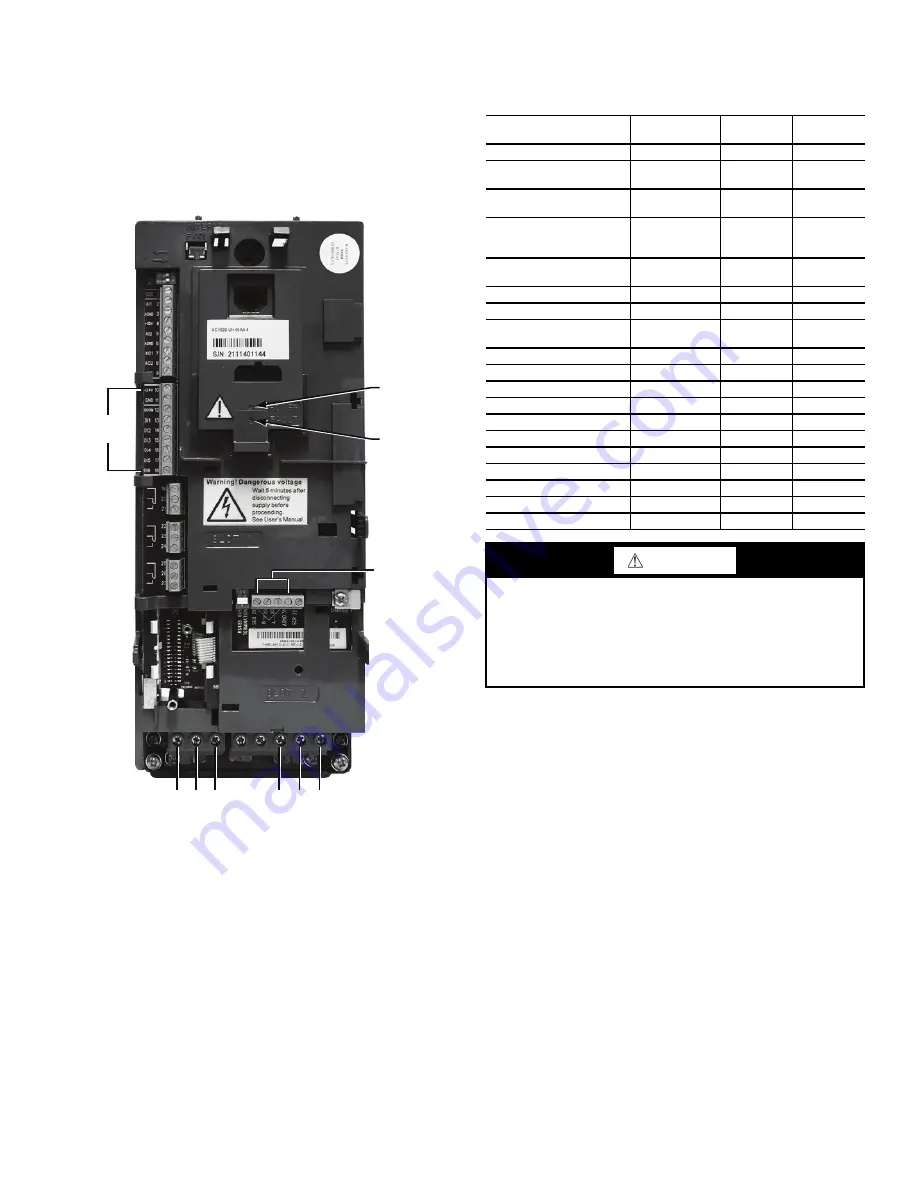

Fig. A — Variable Frequency Drive (VFD) Terminals

and Connections - Unit Shown with Front Cover

Removed

The VFD is factory-configured to match the current and power

requirements for each motor selection and all wiring connections

are completed by the factory; no field adjustments or connec-

tions are necessary. While the basic VFD retains all of its stan-

dard capabilities, this application uses only a limited portion of

these features to provide discrete output speeds to the motor.

Consequently the VFD is not equipped with a keypad. A keypad

is available as an accessory (P/N CRDISKIT001A00) for field-

installation or expanded service access to VFD parameter and

troubleshooting tables. The VFD used has soft start capabilities

to slowly ramp up the speeds, eliminating any high inrush of air

volume during speed changes.

The VFDs communicate to the

Comfort

Link MBB over the local

equipment network (LEN). The VFD speed is controlled directly

by the

Comfort

Link controls over the LEN. The VFD parameters

required to allow the VFD to communicate on the LEN are shown

in Table Q. These are factory set and would only need to be adjust-

ed if replacing the drive. Table R shows VFD parameters that are

set by the

Comfort

Link controls, and sent to the VFD over the

LEN at power up of the VFD. These are hard-coded to be set as

listed. The parameters listed in Table S have corresponding

Com-

fort

Link configurations (

Configuration

I.FAN

S.VFD

). The

factory sets these parameters per motor installed in the unit and

these should not be adjusted in the field. These are only provided

for drive or motor replacement or future adjustments. Table T lists

the status information the VFD sends to the

Comfort

Link controls,

and Table U lists the information the

Comfort

Link controls send to

the VFD. This table is updated at every scan the

Comfort

Link con-

trols perform of the LEN. This occurs approximately once every

second.

TERMINALS

10 – 16

TERMINALS

28 – 31

U1 V1 W1

U2

V2 W2

POWER

LED

FAULT

LED

Table P — VFD Connections

POINT DESCRIPTION

TYPE OF I/O TERMINAL

NUMBER

TERMINAL

NAME

LOW VOLTAGE INPUTS

Low Voltage Power

(jumped to DI1 & DI4)

24vdc 10 24v

Low Voltage Common

(jumped to DCOM)

Ground 11 GND

Discrete Inputs

Common (jumped from

GND)

Ground 12

DCOM

Discrete Input 1

(jumped from 24v)

Switch Input

13

DI1

Not Used

Switch Input

14

DI2

Not Used

Switch Input

15

DI3

Discrete Input 4

(jumped from 24v)

Switch Input

16

DI4

Shielded Cable Ground

Shield 28 SCR

LEN Communication

LEN 29 B+

LEN Communication

LEN 30 A-

LEN Communication

LEN 31

AGND

HIGH VOLTAGE

Voltage Leg from C-11

Voltage Input

U1

MAINS

Voltage Leg from C-13

Voltage Input

V1

MAINS

Voltage Leg from IFTB

Voltage Input

W1

MAINS

Voltage Leg to IFM-3

Voltage Output

U2

MOTOR

Voltage Leg to IFM-2

Voltage Output

V2

MOTOR

Voltage Leg to IFM-1

Voltage Output

W2

MOTOR

WARNING

EQUIPMENT DAMAGE/PERFORMANCE HAZARD

Failure to follow this caution may result in damage to the unit

or

in degradation of unit performance.

Do not run the Carrier Assistant through the VFD keypad.

This will cause parameters to change value that are not de-

sired on these applications.

Summary of Contents for /50HC 04-28

Page 69: ...69 Fig 24 Typical Control Diagram for 48HC 04 14 Units 48HC 08 09 shown ...

Page 70: ...70 Fig 25 Typical Power Diagram for 48HC 04 14 Units 48HC 08 09 shown ...

Page 71: ...71 Fig 26 Typical Control Diagram for 50HC 04 14 Units 50HC 14 shown ...

Page 72: ...72 Fig 27 Typical Power Diagram for 50HC 04 14 Units 50HC 14 Non Humidi MiZer shown ...

Page 73: ...73 Fig 28 Typical Control Diagram 48HC 17 28 Units ...

Page 74: ...74 Fig 29 Typical Control Diagram 50HC 17 28 Units ...

Page 75: ...75 Fig 30 Typical Humid MiZer Power Diagram and Component Arrangement 48 50HC 17 28 Units ...

Page 76: ...76 Fig 31 Typical Non Humid MiZer Power Diagram and Component Arrangement 48 50HC 17 28 Units ...

Page 89: ...89 Fig 42 Modulating ERV Wiring Schematic ...

Page 90: ...90 Fig 43 EnergyX ERV Control Box Component Layouts ...

Page 101: ...101 Fig 59 Exhaust Fan Assembly Removal Exhaust Fan Assembly ...

Page 141: ......