10

Gas Heat (48HC)

Inspect the gas heat section of the unit. Verify the number of

burners match the number of heat exchanger openings and the

burner assembly is properly aligned. If the orifices were

changed out for elevation or Liquid Propane purposes, verify

proper installation. Visually inspect other components in heat

section.

Verify gas pressures before turning on heat as follows:

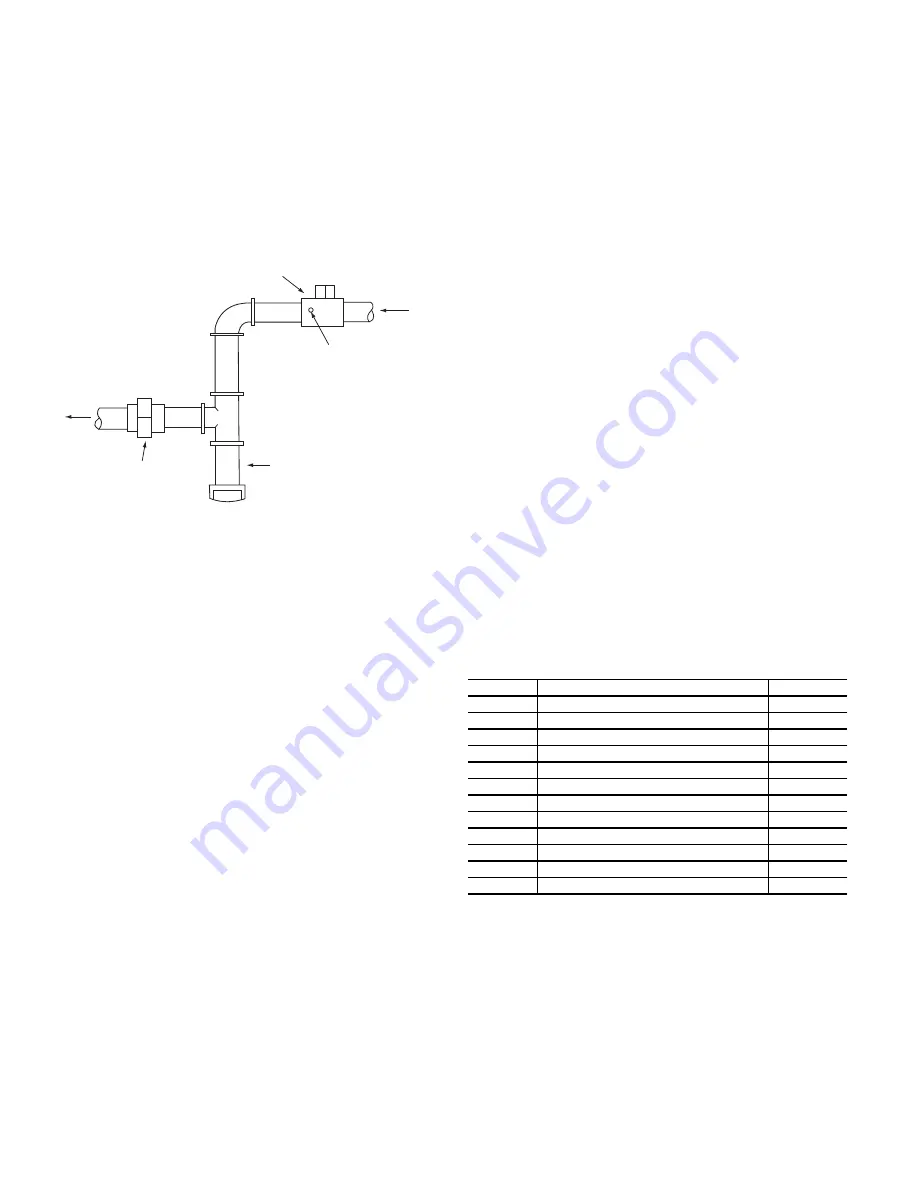

1. Turn off field-supplied manual gas stop, located external

to unit.

2. Connect pressure gauge to supply gas tap, located on field-

supplied manual shutoff valve. (See Fig. 6.)

Fig. 6 — Field Gas Piping

3. Connect pressure gauge to manifold pressure tap.

4. Turn on field-supplied manual gas stop. Enter Service Test

mode by setting

Service Test

TEST

to “ON” using the

scrolling marquee display. Temporarily install the jumper

wire between “R” and “W1” on TB. Use the Service Test

feature to set Service

Test

HEAT

HT.1

to ON (first

stage of heat) using the scrolling marquee.

5. After the unit has run for several minutes, verify the sup-

ply gas pressure is adequate per the base unit installation

instructions. If not, adjust accordingly.

NOTE: Supply gas pressure must not exceed 13.0-in. wg.

6. Set

Service Test

HEAT

HT.1

to OFF using scrolling

marquee.

7. Remove jumper wire if the unit will be operating under

thermostat mode. The jumper must remain if a space tem-

perature sensor (T-55, T-56, T-58, or System Pilot device)

will control the unit.

8. Exit Service Test mode by setting

Service Test

TEST

to

“OFF” using the scrolling marquee.

Units with EnergyX

®

System

BASE UNIT EVAPORATOR FAN

First follow the base unit instructions to balance the RTU in-

door fan. The ERV (Energy Recovery Ventilator) fans should

be off during base unit fan set-up. Before start-up and testing

the ERV, verify that the

Comfort

Link controller minimum

damper positions are set to 0 and if not change them to 0.

Con-

figuration

→

AIR.Q

→

AQ.MN

= 0, and

Configuration

→

ECON

→

MP.MX

= 0. The ERV communicates with the

Comfort

Link controller therefore the scrolling marquee can be

used for test mode and configuration of the ERV. The follow-

ing sections explain ERV testing and configuration. It is im-

portant that these configurations are set correctly in order for

the ERV module to properly control the air performance. Final-

ly, with service test disabled run unit under normal operation,

verify proper supply airflow with ERV and indoor fan running.

START-UP CHECK LIST

Use the EnergyX Unit Start-Up Checklist (see page CL-1) in

conjunction with the base unit Start-Up checklist from the base

Controls book. Fill in all blank data entries that are applicable

to the exact unit being installed. The ERV model and serial

numbers are printed in the ERV control box. Save the checklist

for future service and maintenance use. It is recommended that

a copy of the checklist be left with the unit in the literature slot

on the base unit control box access door.

ERV TEST MODE

ERV Test points should be used when starting up an EnergyX

unit to verify proper ERV component operation. It can also be

used for troubleshooting. To test the ERV, use the scrolling

marquee to put the

Comfort

Link RTU into test mode. Then go

to Test Independent outputs (

Service Test

→

INDP

). Table 3

shows a list of test points that can be tested as independent out-

puts. There are five ERV tests which can be performed sepa-

rately or together while in test mode. Use the scrolling mar-

quee to change the value of the test point. Follow the

Com-

fort

Link Controls, Start-Up, Operation, and Troubleshooting

manual for testing the base rooftop unit.

The 5 ERV specific test points are OAU 2-position Damper,

OAU Wheel Test, OAU OA Fan Speed test, OAU PE Fan

Speed Test and OAU Tempering Heater Test. The 2-position

damper can be opened and closed with the

OA.DM

point. The

2-position damper accessory can be installed on the exhaust

opening of the ERV. The ERV wheel motor can be turned on

and off with the WHL point. The ERV’s outside air (

OA.OF

)

and building exhaust air (

OA.XF

) motors can be ramped up

and down during test mode their corresponding fan speed test

points. Table 3 shows the test mode test points in the order they

appear under test mode. Communication failures will not allow

these ERV test points to be changed. The

Comfort

Link control-

ler will show active alarms during test mode.

NOTE: If a 2-position damper is installed, it must be opened in

test mode while operating the exhaust test.

ERV CONFIGURATION

The ERV configuration menu can be accessed using the

Com-

fort

Link controller scrolling marquee. Enter the Outside Air

Unit Configurations (

Configuration

→

OAU

) menu. Table 12

shows the list of complete outside air unit configurations that

can be changed and the defaults from the factory. The critical

job specific configurations are listed below and should be

changed at start up for the specific job site. See the operation

section for details all configurations.

OAU Unoccupied Operation (U.RUN)

This allows the ERV to run during the unoccupied period when

the rooftop fan is brought on.

MANUAL SHUT OFF

(FIELD SUPPLIED)

PRESSURE TAP

(1/8˝ NPT PLUG)

GAS

SUPPLY

SEDIMENT TRAP

UNION

TO

UNIT

Table 3 — Service Test Mode Independent Test

Points

ITEM

EXPANSION

RANGE

INDP

Test Independent Outputs

ECON

Economizer Position Test

0 to 100

E.CAL

Calibrate Economizer

Off/On

PE1

Power Exhaust 1 Test

Off/On

PE.2

Power Exhaust 2 Test

Off/On

ALRM

Alarm Relay Test

Off/On

CCH

Crankcase Heat Test

Off/On

OA.DM

OAU 2-Position Damper

Close/Open

WHL

OAU Wheel Test

0 to 100

OA.OF

OAU OA Fan Speed Test

0 to 100

OA.XF

OUA PE Fan Speed Test

0 to 100

OA.HT

OAU Tempering Heater Test

0 to 100

Summary of Contents for /50HC 04-28

Page 69: ...69 Fig 24 Typical Control Diagram for 48HC 04 14 Units 48HC 08 09 shown ...

Page 70: ...70 Fig 25 Typical Power Diagram for 48HC 04 14 Units 48HC 08 09 shown ...

Page 71: ...71 Fig 26 Typical Control Diagram for 50HC 04 14 Units 50HC 14 shown ...

Page 72: ...72 Fig 27 Typical Power Diagram for 50HC 04 14 Units 50HC 14 Non Humidi MiZer shown ...

Page 73: ...73 Fig 28 Typical Control Diagram 48HC 17 28 Units ...

Page 74: ...74 Fig 29 Typical Control Diagram 50HC 17 28 Units ...

Page 75: ...75 Fig 30 Typical Humid MiZer Power Diagram and Component Arrangement 48 50HC 17 28 Units ...

Page 76: ...76 Fig 31 Typical Non Humid MiZer Power Diagram and Component Arrangement 48 50HC 17 28 Units ...

Page 89: ...89 Fig 42 Modulating ERV Wiring Schematic ...

Page 90: ...90 Fig 43 EnergyX ERV Control Box Component Layouts ...

Page 101: ...101 Fig 59 Exhaust Fan Assembly Removal Exhaust Fan Assembly ...

Page 141: ......