62-11640

2–8

2.3.14

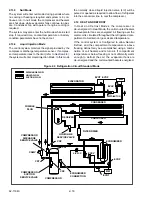

Receiver

Liquid refrigerant from the condenser flows into the

receiver. The receiver serves as a liquid reservoir when

there are surges due to load changes in the system, as

a storage space when pumping down the system and

as a liquid seal against the entrance of refrigerant gas

into the liquid line. The receiver is provided with two

bulls-eye sight glasses, for the observation of liquid

level & moisture content, and a fusible plug.

2.3.15

AutoFresh Air Exchange

As perishable products respire, they consume oxygen

(O

2

) and give off carbon dioxide (CO

2

). This will eventu-

ally cause the atmosphere in a refrigerated compart-

ment to have higher levels of CO

2

and lower levels of

O

2

. This may adversely affect the shelf life of some sen-

sitive perishable products. When transporting these

products, it may be desirable to maintain normal atmo-

spheric conditions (prevent build up of CO

2

and deple-

tion of O

2

) by using fresh air exchange, in addition to

accurate temperature control. The AutoFresh Air

Exchange (

) controls the amount of fresh air

entering the refrigerated compartment without manual

intervention while in transit. AutoFresh Air Exchange

can also be used to lower humidity level in a refrigerated

compartment if ambient air has a lower humidity level.

AutoFresh Air Exchange is a factory-installed option,

as it requires a modified evaporator pod. When air is

being exchanged, two air ports open. The upper port

allows fresh ambient air to enter while stale air exits

through the lower port.

2.4

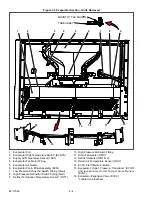

EVAPORATOR SECTION

The evaporator (

) fits into a rectangular

opening in the upper portion of the front wall of the

refrigerated compartment. When the unit is installed,

the evaporator section is located inside the compart-

ment, and the condensing section is outside.

The evaporator assembly consists of an evaporator

coil, evaporator fan, evaporator expansion valve, evap-

orator outlet pressure transducer, evaporator outlet

temperature sensor, defrost termination temperature

sensor, supply temperature sensor and return air tem-

perature sensor.

Heating and defrost is accomplished by electric heat-

ers mounted on the coil.

2.4.1

Evaporator Coil

The evaporator is a tube in fin type. The operation of

the compressor maintains a reduced pressure within

the coil. At this reduced pressure, the liquid refrigerant

evaporates at a temperature sufficiently low enough to

absorb heat from the air. Air movement over the coil is

provided by the evaporator fan and motor (EVM)

assembly.

The electric heaters (HTR1 & HTR2) are mounted on

the inlet side of the coil and in the drain pan.

Automatic evaporator coil defrosting is initiated by

either a defrost air switch (DAS

−

which senses the

pressure drop across the coil) or by the control system

defrost timer. During defrost the refrigeration system is

shut down and the evaporator fan and heaters oper-

ated as required by the defrost mode.

2.4.2

Evaporator Expansion Valve (EVXV)

The EVXV is an automatic device which controls the

flow of liquid to the evaporator according to changes in

superheat of the refrigerant leaving the evaporator. The

expansion valve maintains a relatively constant degree

of superheat in the gas leaving the evaporator regard-

less of suction pressure. The valve has a dual function

- automatic expansion control and prevention of liquid

return to the compressor.

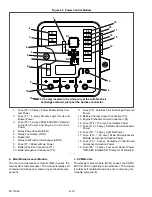

2.4.3

Evaporator Switches, Transducers and

Sensors

a. Evaporator Outlet Pressure Transducer (EVOP)

The EVOP is located in the suction line near the evapo-

rator expansion valve. It provides the control system

with evaporator outlet pressure information to be dis-

played, recorded in the DataLink data recorder and

used to determine the required position of the evapora-

tor expansion valve.

b. Evaporator Outlet Temperature Sensor (EVOT)

The EVOT is a thermistor type sensor located on the

suction line near the evaporator expansion valve. It

provides the control system with evaporator outlet tem-

perature information to be displayed, recorded in the

DataLink data recorder and used to determine the

required position of the evaporator expansion valve.

c. Evaporator High Temperature Switch (EVHTS)

EVHTS is a safety switch which opens on a tempera-

ture rise to de

−

energize the electric heaters if the tem-

perature reaches the cutout point. It is located on the

curbside tube sheet of the evaporator coil.

d. Defrost Termination Temperature Sensor (1DTT)

The defrost termination temperature sensor is located

on the roadside tube sheet of the evaporator coil. It

provides the control system with evaporator tempera-

ture information to be displayed, recorded in the Data-

Link data recorder and used to determine termination

of defrost.

e. Return Air Temperature Sensor (1RAT)

The 1RAT is a thermistor type temperature control

probe which provides the control system with informa-

tion on the temperature of the air entering the evapora-

tor section. The reading is displayed, recorded in the

DataLink data recorder and used to control the refriger-

ation system. It is located on a bracket behind the cen-

ter of the return air grille.

Summary of Contents for Vector 8500

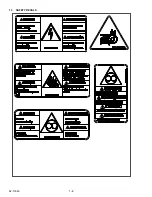

Page 23: ...62 11640 1 6 1 3 SAFETY DECALS ...

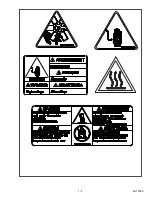

Page 24: ...1 7 62 11640 62 03958 ...

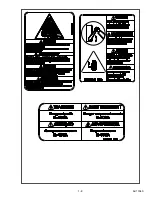

Page 25: ...62 11640 1 8 ...

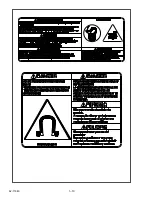

Page 26: ...1 9 62 11640 ...

Page 27: ...62 11640 1 10 ...

Page 125: ...62 11640 SECTION 6 MESSAGECENTER PARAGRAPH NUMBER Page 6 1 MESSAGECENTER MESSAGES 6 1 ...

Page 321: ......

Page 322: ......