GB / IE / NI

77

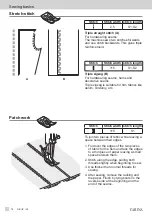

Sewing basics

Monogramming and embroidering with embroidery hoop*

Stitch

Stitch width stitch length

1~5

0

Attach the embroidery and darning

plate

1. Remove the presser foot and the

presser foot holder.

2. Attach the embroidery and darning plate

(o).

3.

Lower the two-step presser foot lifter

(18) before starting to sew.

4. Adjust the stitch width according to the

size of lettering or design.

Preparation for monogramming and

embroidering*

1. Draw the desired lettering or design on

the right side of the fabric with the use

of a water-soluble fabric marker.

2. Stretch the fabric between the

embroidery hoop as firmly as possible.

3.

Place the fabric under the needle.Lower

the two-step presser foot lifter (18).

4. Turn the hand wheel (21) towards you

to bring up the lower thread through the

fabric. Sew a few securing stitches at

the starting point.

5. Hold the hoop with thumb and

forefingers of both hands.

6. Coordinate the sewing speed and the

movement of hoop.

* The embroidery hoop is not supplied with the

machine.