10

+

Check the tightness of all screw connections once a month.

+

equipment, we recommend having the equipment regularly maintained (at least

once a year) by specialists (service technicians of your contract partner).

+

The equipment may be cleaned of dust, dirt and sweat using a damp cloth. The

use of solvents should be strictly avoided. Also, make sure that no liquids (e. g.

sweat) get into the openings of the equipment (e. g. console).

2.2

Faults and Troubleshooting

The equipment runs through regular quality controls during production. Nevertheless,

errors or malfunctions on the equipment may occur. Individual parts are often the

to see the six most common errors and how to repair them. If the equipment still does

not work properly, please contact your contract partner.

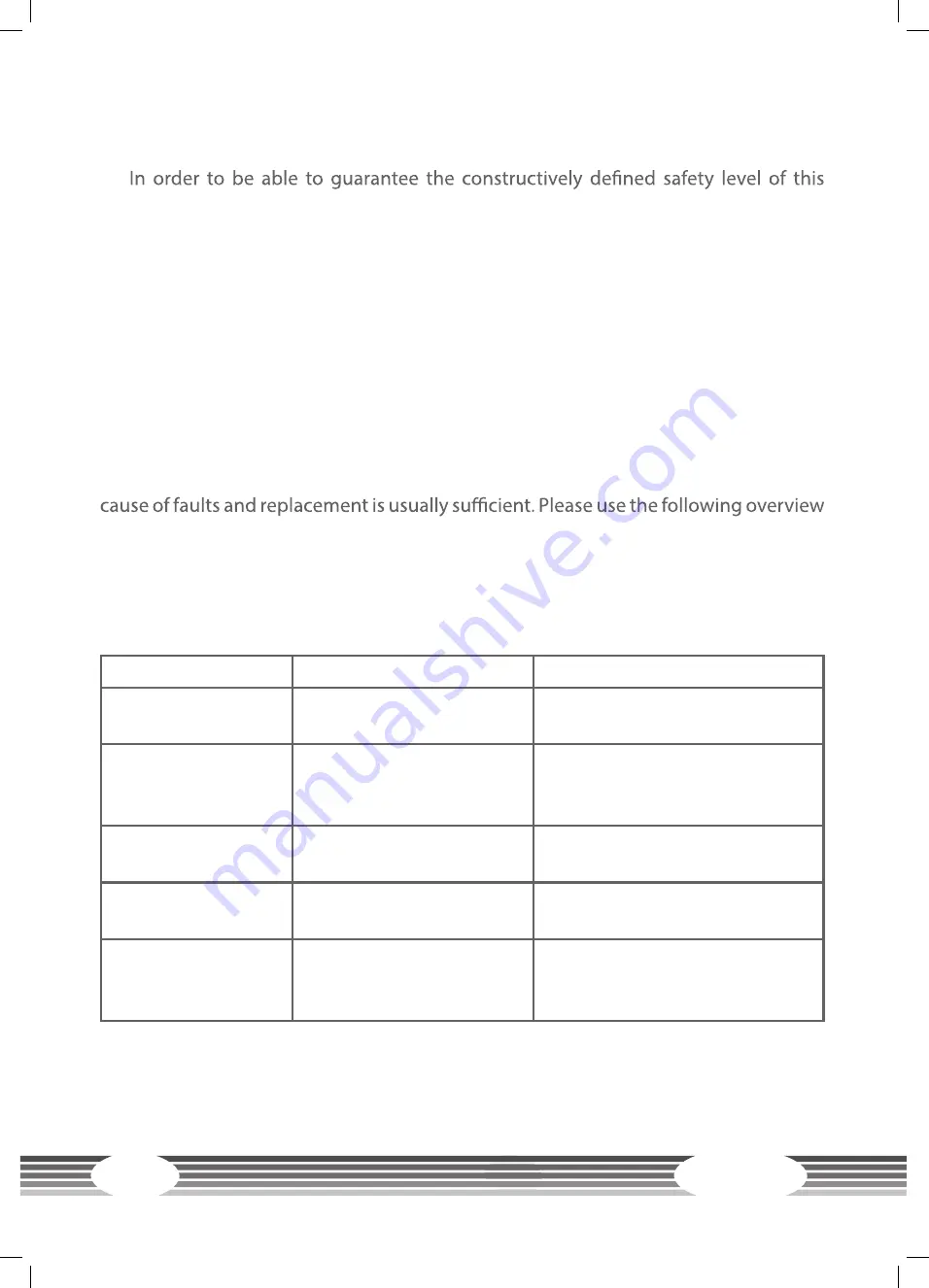

Problem

Cause

Solution

Drive discs wobble

or make noises

Drive pulley is loose

Tighten nuts

Display does not

work

No plug connection,

power supply not

plugged in

Check all plug connections

and see if the power supply is

plugged in

Footplates are

creaking

Footplates are loose

Tighten up the footplate screws

Creaking noises

Screws are loose

Check screws are properly

tightened

Guide rails are

squeaking

Guide rails or rollers are

dirty or the guide rails are

dry

Clean the guide rails, then

lubricate with a non greasy

silicone

FX

70