7

The chimney must be swept before connection to the stove and swept every

twelve months thereafter. It is recommended that your chimney is swept every

six months.

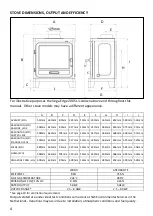

An existing fireplace opening can be modified to accommodate the stove. The

following pages identify some typical installation scenarios and provides the

necessary specific installation information for your new stove. Always consult

your stove supplier for a detailed survey of your particular circumstances.

To make it easier to handle the stove on installation, remove the baffle plates,

bricks and door. Place in a secure place to avoid damage. Refit after

installation.

Upon completion of installation, the appliance should be checked under fire for

soundness of joints and seals, and also that all smoke and fumes are taken from

the appliance, up the chimney and emitted safely.

Typical Installation for Inglenook Fireplaces – top flue

Inglenook fireplaces can have very

large bore chimneys. Check with your

installer – you are likely to require a

stainless steel flexible liner for solid

fuel if your chimney is larger than

230mm x 230mm. A closure plate

with access for cleaning may also be

required together with a short length

of flue pipe of the same diameter as

the stove flue collar.