- 16 -

Preventing Chip Out

As noted previously, when the SIDE and

FRONT/BACK pieces are inserted into the machine,

they are offset a bit so they’ll match correctly when

assembled. In other words, the SIDE will rest slightly

to the right of the FRONT/BACK in the machine. This

leaves the right edge of the SIDE exposed without

the “chip breaker” effect that the FRONT/BACK

provides for the rest of the SIDE (see Figure 28). This

may result in an unsatisfactory cut at the edge of the

SIDE.

This problem is resolved simply by taking a two

inch-plus wide “back-up” board, of the same

thickness as the workpiece, and clamping it

horizontally next to the FRONT/BACK piece, so that it

backs up the exposed edge of the SIDE, as shown in

Figure 28. You can use this piece over and over

again.

Dovetails in Plywood

Because plywood handles a bit differently than solid

stock, here are some tips to follow:

1. When using plywood, the layers tend to be more

fragile. Therefore, the operator should keep the

movement of the cutting unit consistent and

proceed relatively slowly.

2. On the rounded arcs of the tenon cuts, you may

lose a bit of the top layer. This is to be expected

with plywood, and does not affect either the look or

the strength of the assembled dovetail joint.

Rather, the strength of the dovetailed corner comes

from the flat side of the tenons.

3. Plywood has a tendency to chip out on exposed

edges. A back-up board may be necessary (see

Figure 28).

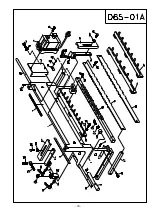

Figure 28

(view from rear of machine)

Maintenance

Before doing

maintenance on the machine, disconnect it

from the electrical supply and the air supply,

and release any residual air from the lines.

Failure to comply may cause serious injury.

If the power cord is worn, cut, or damaged in

any way, have it replaced immediately.

The horizontal and vertical tables and other

exposed metal parts should be kept clean and

free of rust. A coat of paste wax will help protect

the tables from tarnishing.

After each day’s use, brush or blow out dust and

debris from the cutter, table, motor, etc.

Keep the clamping cylinders clean to prevent

debris adhering to them, which can scar

workpieces.

Keep clean the travel rods upon which the

headstock slides.

Lubrication

The linear bushings by which the headstock

travels on the rods are pre-lubricated and

sealed; they do not require additional

lubrication.

The spindle unit is also sealed and requires

no lubrication.

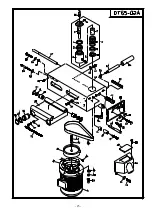

Occasionally check the oil level in the oil

regulator cup (see Figure 24). Add more oil as

needed. Use standard air tool oil.