Chapter 3

3-4

F-3-6

3.3.3 Auxiliary Tray Lift Control

0020-4694

In response to an increase in the number of folded sheets in the tray, the auxiliary tray is moved up to prevent a delivery jam associated with the tray B (memo) by

making sure that the lead and trail edges of the stacks deposited in the tray will be even.

The auxiliary tray is moved by operating the solenoid (SL9) according to the instructions from the finisher controller PCB.

F-3-7

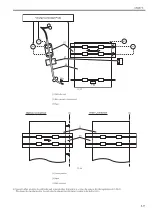

[1] Tray A lift motor drive signal

[3] Tray B lift motor drive signal

[2] Tray A lift motor rotation detection signal

[4] Tray B lift motor rotation detection signal

M22: Tray A lift motor

PS34: Tray A lift motor rotation sensor

M23: Tray B lift motor

PS35: Tray B lift motor rotation sensor

Finisher controller PCB

PS34

PS35

Tray A

Tray B

[1]

[2]

[3]

[4]

M22

M23

Finisher controller PCB

Tray B

Tray A

[1]

M23

SL9

Auxiliary tray

Summary of Contents for Saddle Finisher-AF2

Page 1: ...SERVICE MANUAL Saddle Finisher AF2 MARCH 6 2009...

Page 2: ......

Page 6: ......

Page 12: ...Contents...

Page 13: ...Chapter 1 Specifications...

Page 14: ......

Page 16: ......

Page 22: ......

Page 23: ...Chapter 2 Installation...

Page 24: ......

Page 26: ......

Page 55: ...Chapter 3 Functions...

Page 56: ......

Page 58: ......

Page 104: ...Chapter 3 3 46...

Page 105: ...Chapter 4 Parts Replacement Procedure...

Page 106: ......

Page 110: ......

Page 157: ...Chapter 4 4 47 F 4 213 3 2 1...

Page 158: ......

Page 159: ...Chapter 5 Maintenance...

Page 160: ......

Page 209: ...Chapter 5 5 47 F 5 221 SW382 SW381 SW383 ENTER SW384 SW385 DSP381 1...

Page 218: ......

Page 219: ...Appendix...

Page 220: ......

Page 221: ...General Timing Chart General Circuit Diagram Finisher Sorter DeliveryTray Saddle Finisher AF2...

Page 222: ......

Page 224: ......

Page 225: ...Contents 1 General Circuit Diagram 1 Signal Names 1 General Circuit Diagram 9...

Page 226: ......

Page 243: ......

Page 244: ......