Installation Procedure

1. Open the Front Cover.

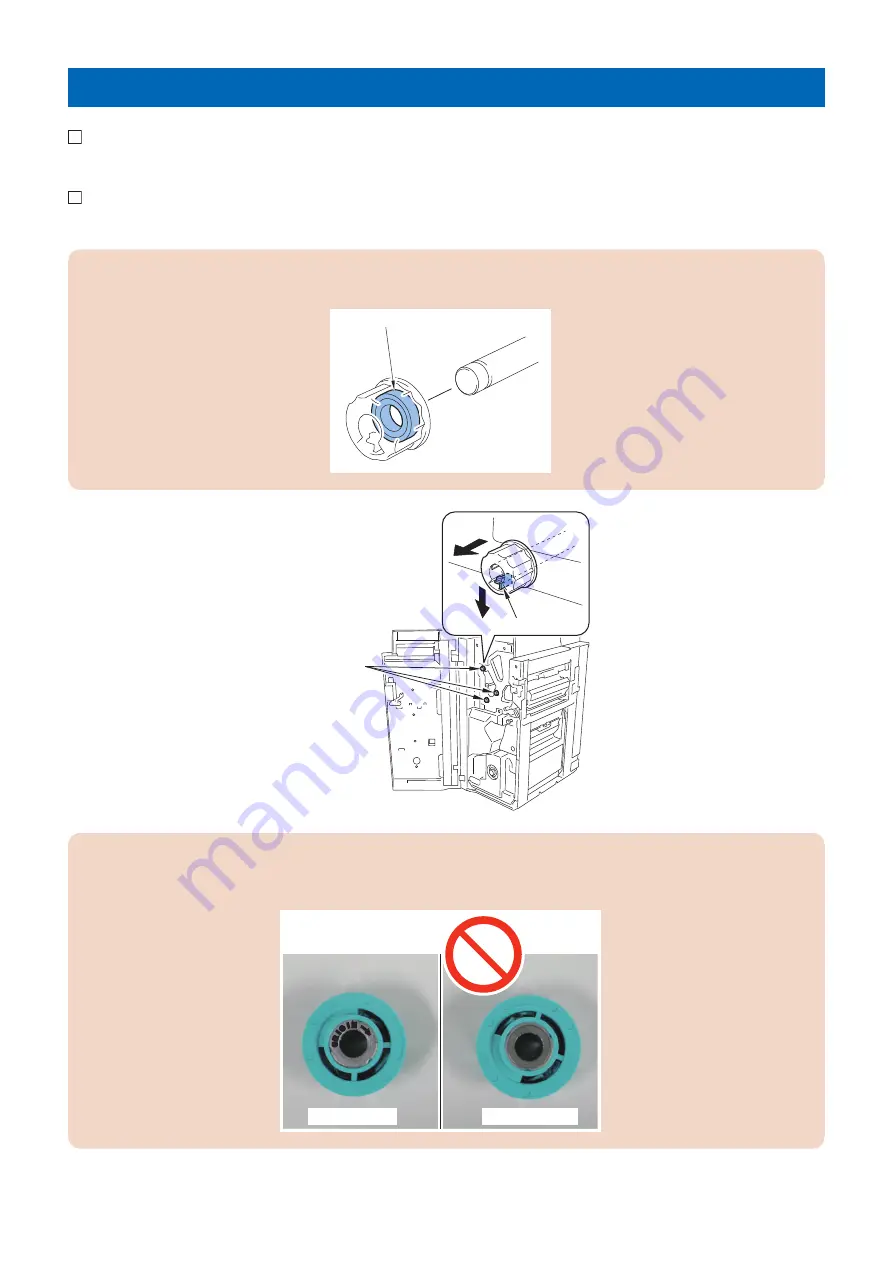

2. Push the claw in the direction of the arrow[A] and remove the 3 knobs in the direction of the arrow[B].

CAUTION:

Be careful not to drop the bearing inside the knob.

Bearing

[A]

[B]

Claw

Knobs

CAUTION:

• If the bearing fell off from the knob, reattach it.

• A bearing has the orientation so make sure to install it in the correct direction.

No inscription

With inscription

4. Installation

19

Summary of Contents for Puncher Unit-BS1

Page 5: ...Safety Precautions Notes Before it Works Serving 2 Points to Note at Cleaning 2 ...

Page 7: ...Product Overview 1 Specifications 4 Names of Parts 6 ...

Page 11: ...Technology 2 Feed Drive System 8 ...

Page 15: ...Disassembly Assembly 3 Removing from the Host Machine 12 Drive System 14 ...

Page 17: ...6 Remove the punch unit 1 2 screws 2 1 2 2x 3 Disassembly Assembly 13 ...

Page 26: ...7 Remove the Rear Cover 2 Screws Loosen 6 Screws 6x 2x 4 Installation 22 ...