2-4. Warnings

2-5. Troubleshooting by Symptom

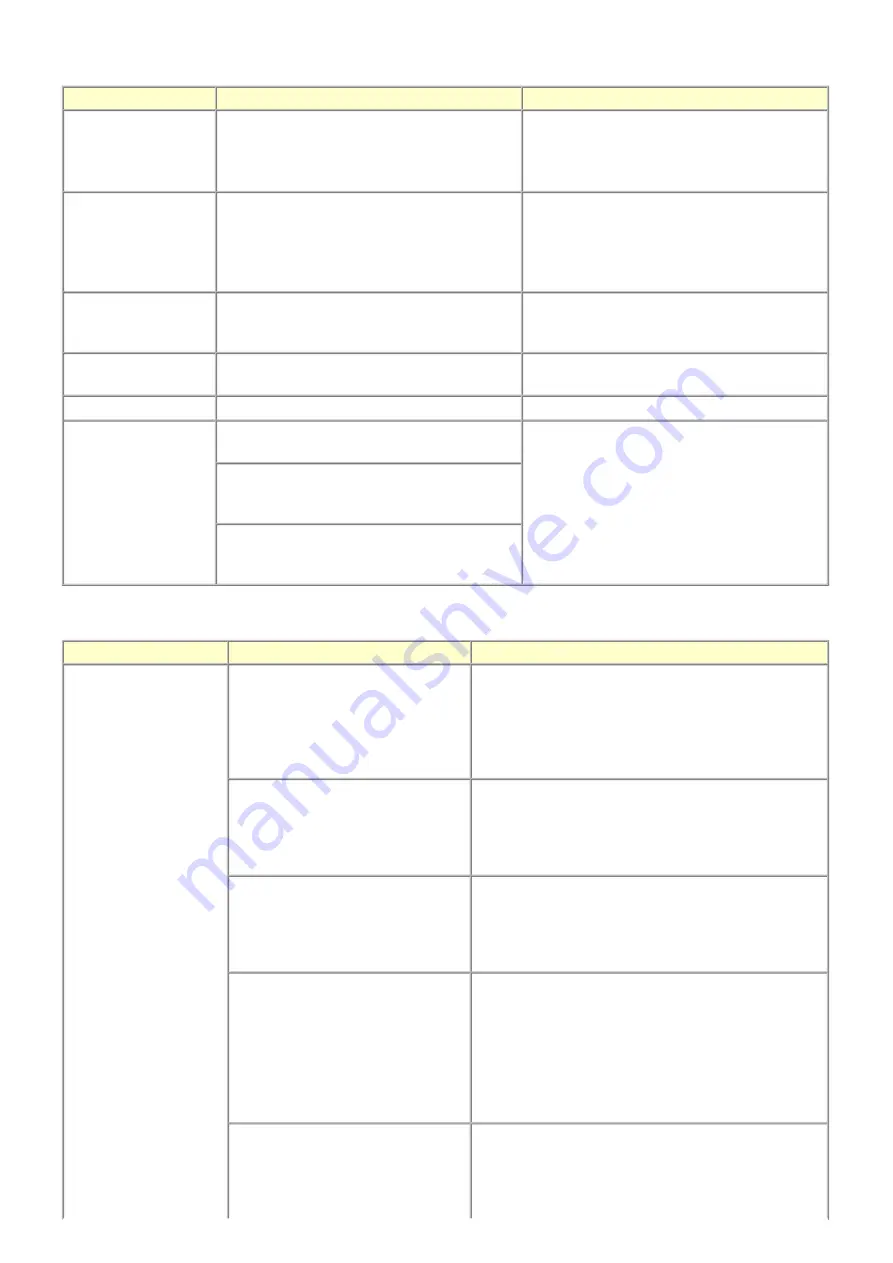

Warning

Message on the LCD

Solution

Low ink

"!" is indicated for an applicable ink tank icon in

the Status Monitor.

No special solution.

Since the ink will be used up soon, prepare for a

new ink tank.

Print head temperature

rise

If the print head temperature does not fall, the print

head error will occur.

When the print head temperature falls, the error is

automatically cleared.

If the print head error is indicated, repair servicing

is required.

Protection of excess rise

of the print head

temperature

If the print head temperature does not fall, the print

head error will occur.

If the print head temperature exceeds the specified

limit, an intermission is inserted during printing.

Restrictions on paper

The current paper cannot be set. Change the size

and type.

Re-select the supported paper type and size.

USB cable not connected Set the PC to start scan.

Connect the USB cable, then turn on the computer.

Cancellation of image

select information

Reset the selected photo information?

Yes No

- Select

Yes

, and press the OK button.

=> The image selection is cancelled, and the

menu or sub-menu is displayed.

- Select

No

, and press the OK button.

=> The LCD returns to the display immediately

before the message was displayed.

Do you want to clear the image scanned from the

photo?

Yes No

Do you want to clear the scanned image and

rescan?

Yes No

Symptom

Solution

Faulty operation

The power does not turn on.

The power turns off immediately after

power-on.

- Confirm the connection of

- the power cord, and

- between the logic board and the power supply unit.

- Replace the

- power supply unit, or

- logic board.

A strange noise occurs.

- Remove foreign material.

- Attach a removed part if any.

- Check the operation of the moving parts (such as purge

unit, carriage unit, and paper feeding mechanism)

- Replace a faulty part, if any.

Nothing is displayed on the LCD.

- Confirm the connection between the operation panel, the

LCD unit, and the logic board.

- Replace the

- operation panel unit, or

- logic board.

A portion of the LCD is not displayed.

The display flickers.

- Perform the button and LCD test in the service mode, and

confirm that the LCD is displayed without any segments

missing or flickering.

- Confirm the connection between the operation panel, the

scanning unit, and the logic board.

- Replace the

- operation panel unit, or

- logic board.

Paper feed problems (multi-feeding,

skewed feeding, no feeding).

- Examine the inside to confirm that no parts are damaged,

and the rollers are clean.

- Remove foreign material.

- Adjust the paper guide properly.

9 / 43

Summary of Contents for PIXMA MP610 Series

Page 19: ...6 Remove the main case Release the 4 claws and pull up the main case no screws 17 43 ...

Page 26: ...24 43 ...

Page 35: ...LF Eject correction flowchart 33 43 ...

Page 38: ...Left margin correction flowchart 36 43 ...

Page 39: ...37 43 ...

Page 44: ... 2 Ink absorber counter value print Print sample 3 4 Verification Items 42 43 ...