Outline

Figure 3-39 shows the basic construction of the

system.

When the pick-up clutch solenoid

or SL2)

goes

the main motor (MI) rotating, the

drive of the main motor causes the pick-up roller to

thereby movingthe paperto feeder roller 1 or

2.

Afterhaving

paper moved by the registration roller so that

the leading edge of the image

the photosensitive

drum and that of the

paper match; thereafter,

the paper sent thetransfer

separation

feeder

fixing assembly, delivery

and to the

The path along which the

paper moves

provided with photointerrupters (Q3,

servicing

as the pre- registration and separation

and

If the paper fails to

or pass the

within

a specific period oftime, thecondition identified as

a

and the JAM

the control panel

starts to flash.

The counter

by one when the delivery

sensor

the trailing edge of the

paper.

The control

the other hand,

the count response to

pick-up.

The

of paper the upper and lower

cassettes checked by photointerrupters

if paper absent, the cassette out

(UPCPD,

control panel starts to flash.

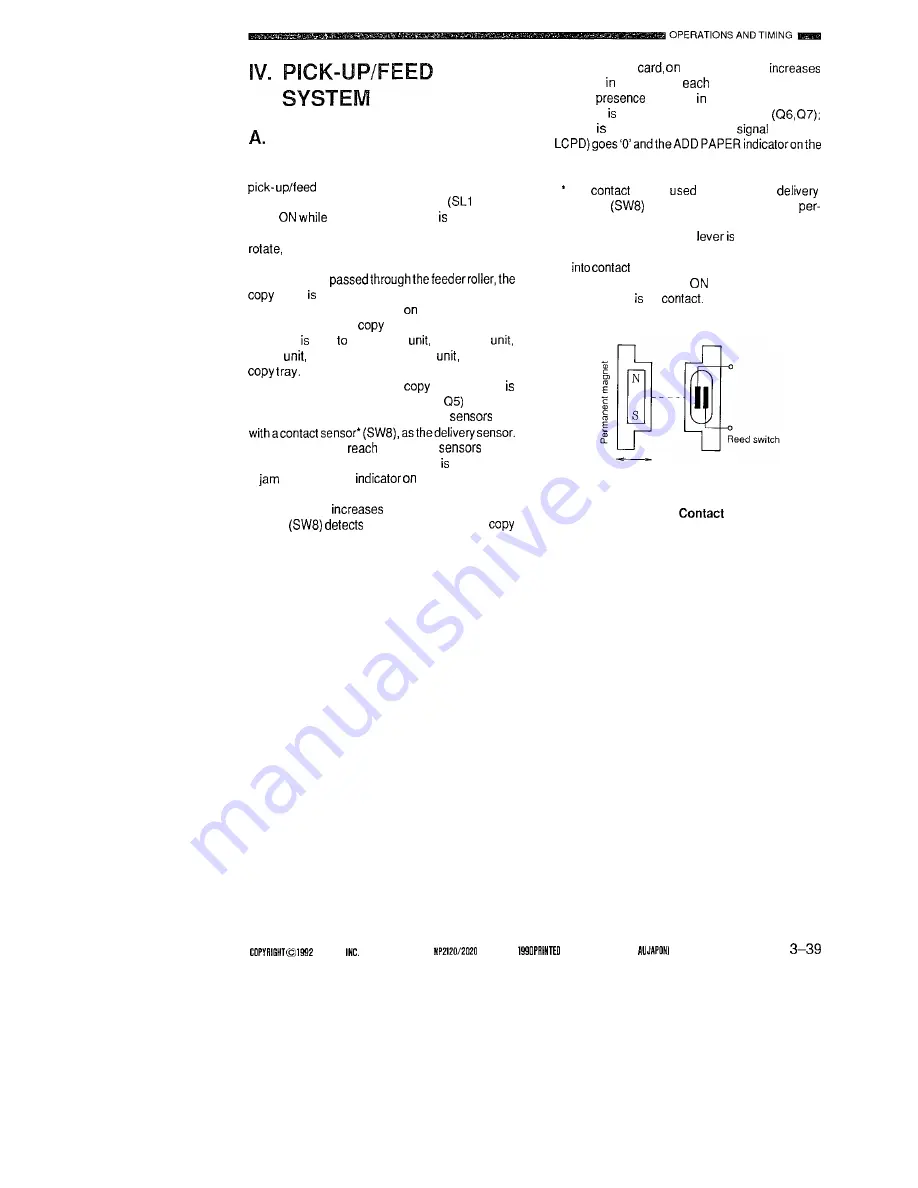

The

sensor

as the copier’s

sensor

makes use of attraction of a

manent magnet to drive the reed switch.

The paper detection

equipped with a

permanent magnet and, when the magnet comes

with the reed switch, the switch goes

OFF; the switch goes

(paper resent) when

the magnet off

Figure 3-38

Sensor

C A N O N

C A N O N

RN.0 MAY

IN JAPAN [IMPRIME

Summary of Contents for NP-2020

Page 5: ......

Page 171: ...LL w I n t 0 m a 9zcr 9zcr ...

Page 172: ...I I i I am w m h I I r l I I B m 0 4 u I m ll ...