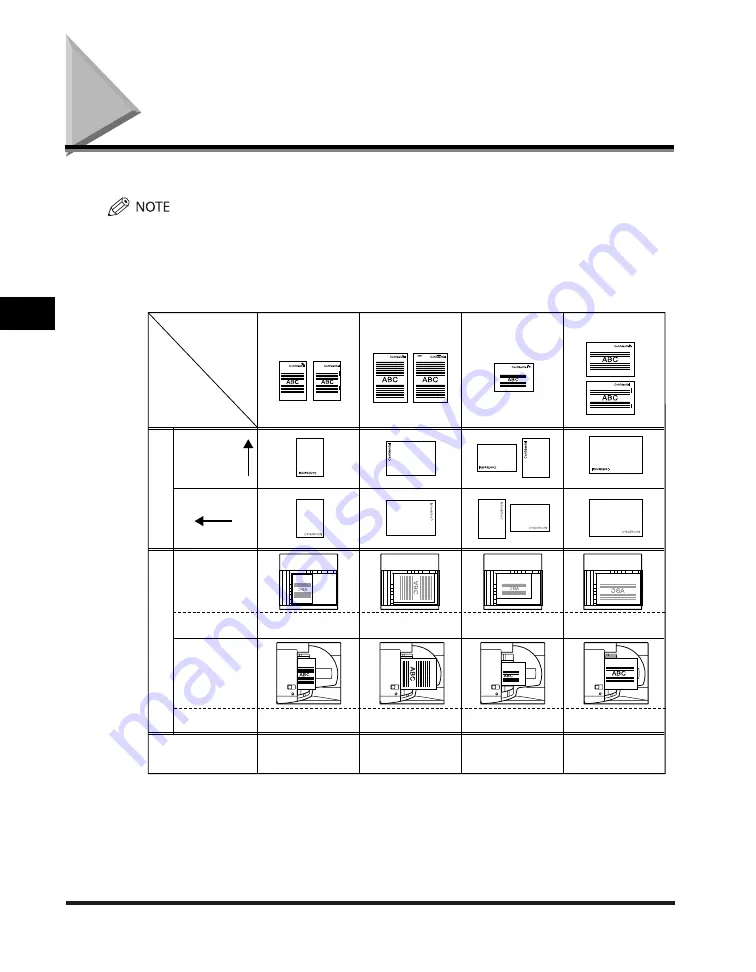

Relationship between Original Orientation and Preprinted Paper Output Chart

4-50

4

Appendix

Relationship between Original Orientation and

Preprinted Paper Output Chart

Please use this chart when printing on preprinted paper (i.e., paper with logos or letterheads).

If you want to copy on the back side of preprinted paper, place the side you want to copy on:

face up when using a paper drawer

face down when using the stack bypass or the optional Paper Deck-Q1

If You Want to Set Right Side Stapling:

Double: Right

11"x17", LGL, LTRR

Corner: Bottom Right

Double: Right

Output

Example

Staple

Position

Original/

Paper

Orientation,

Settings

Corner: Top Right

Double: Right

Corner: Top Right

Double: Right

Corner: Top Right

Double: Right

Corner: Top Right

Double: Right

Original side:

Face down

Original side:

Face up

Preprinted side:

Face down

Orig

inal

P

reprint

ed P

aper

Preprinted side:

Face up

LTR

LTR

Corner: Top Right

Double: Top

Corner: Top Right

Double: Right

Corner: Top Right

Double: Right

Corner: Top Right

Double: Right

Corner: Top Right

Corner: Top Right

Corner: Top Right

11"x17", LGL, LTRR

Orientation on

the platen glass

Orientation in

the feeder

Staple position

Staple position

Auto Orientation Setting

Either On or Off

Either On or Off

Either On or Off

Either On or Off (Set to 'On'

when paper orientation in the

paper deck/stack bypass/paper

drawer is vertical.)

Orientation in stack

bypass/paper deck

Orientation in

paper drawer

-

-

●

Summary of Contents for iR3245

Page 2: ......

Page 3: ...iR3245 iR3235 iR3230 iR3225 Troubleshooting...

Page 58: ...Main Power and Control Panel Power 1 24 1 Before You Start Using This Machine...

Page 122: ...Consumables 2 64 2 Routine Maintenance...

Page 256: ...Sample Reports 4 24 4 Appendix...

Page 288: ...Index 4 56 4 Appendix...

Page 292: ...System Management of the iR3245 iR3235 iR3230 iR3225 4 60 4 Appendix 2 Press System Settings...

Page 298: ...System Management of the iR3245 iR3235 iR3230 iR3225 4 66 4 Appendix...

Page 299: ......