Chapter 13

13-17

F-13-34

- If the value is not as indicated, make the following

adjustments:

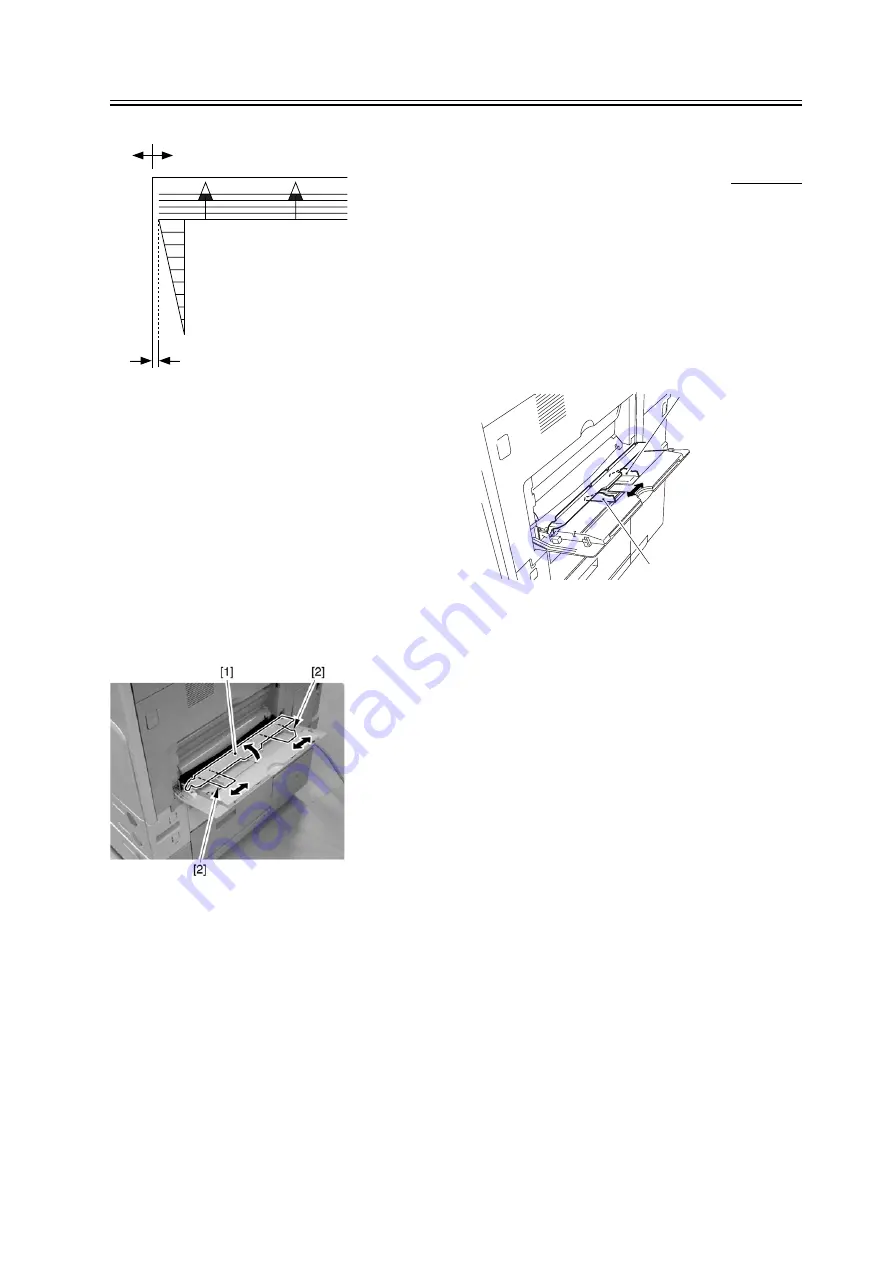

3) Remove paper from the manual feed tray.

4) Loosen the fixing screw [1] on the top cover of the

manual feed tray.

5) While referring to the index you checked in step 2),

move the top cover of the manual feed tray back

and forth. Moving the top cover of the manual feed

tray toward the rear of the machine will increase the

front margin.

F-13-35

6) Tighten the fixing screw on the top cover of the

manual feed tray.

7) Put paper in the manual feed tray.

8) Make a copy using the manual feeder as the source

of paper, and check to make sure that the margin along

the front is 2.5 +/-1.5 mm.

13.6.4

Registering the

Paper Width Basic Value

0007-4926

iR2270 / iR2870 / iR3570 / iR4570 / iR3530

1) Turn on the main power switch.

2) Register the paper width basic value for A4R as

follows:

2-1) Match the manual feed side guide [1] against the

A4R marking.

F-13-36

2-2) Start service mode, and select 'register manual

feed d A4R width'.

CPOIER>FUNCTION>CST>MF-A4R

2-3) Press the OK key to save the new A4R width.

3) Register the paper width basic value for A4 as

follows:

3-1) Mach the manual feed guide against the A4

marking.

3-2) In service mode, select 'manual feed A4 width'.

CPOIER>FUNCTION>CST>MF-A4

3-3) Press the OK key to save the new A4 width.

4) Register the paper width basic value for A6R as

follows:

4-1) Match the manual feed side guide against the

A6R marking.

4-2) In service mode, select 'register A6R width'.

CPOIER>FUNCTION>CST>MF-A6R

4-3) Press the OK key to save the new A6R width.

0

2

4

6

8

10

(-)

(+)

2.5±1.5mm

[1]

[1]

Summary of Contents for iR2270 Series

Page 1: ...Jan 31 2005 Service Manual iR4570 3570 2870 2270 Series ...

Page 2: ......

Page 6: ......

Page 29: ...Chapter 1 Introduction ...

Page 30: ......

Page 106: ......

Page 107: ...Chapter 2 Installation ...

Page 108: ......

Page 110: ......

Page 132: ...system setup network Ethernet driver setup auto detect ...

Page 152: ...F 2 94 3 2 3 1 ...

Page 153: ...Chapter 3 Basic Operation ...

Page 154: ......

Page 156: ......

Page 162: ......

Page 163: ...Chapter 4 Main Controller ...

Page 164: ......

Page 204: ......

Page 205: ...Chapter 5 Original Exposure System ...

Page 206: ......

Page 253: ...Chapter 6 Laser Exposure ...

Page 254: ......

Page 256: ......

Page 270: ......

Page 271: ...Chapter 7 Image Formation ...

Page 272: ......

Page 276: ......

Page 289: ...F 7 13 1 2 3 4 ...

Page 348: ......

Page 349: ...Chapter 8 Pickup Feeding System ...

Page 350: ......

Page 356: ......

Page 511: ...Chapter 9 Fixing System ...

Page 512: ......

Page 556: ......

Page 557: ...Chapter 10 External and Controls ...

Page 558: ......

Page 562: ......

Page 632: ......

Page 633: ...Chapter 11 MEAP ...

Page 634: ......

Page 636: ......

Page 641: ...Chapter 12 Maintenance and Inspection ...

Page 642: ......

Page 644: ......

Page 680: ......

Page 681: ...Chapter 13 Standards and Adjustments ...

Page 682: ......

Page 684: ......

Page 703: ...Chapter 14 Correcting Faulty Images ...

Page 704: ......

Page 754: ...T 14 28 Notation Description VR201 for factory use ...

Page 755: ...Chapter 15 Self Diagnosis ...

Page 756: ......

Page 758: ......

Page 841: ...Chapter 16 Service Mode ...

Page 842: ......

Page 844: ...Contents 16 8 1 COPIER 16 102 16 8 1 1 Copier List 16 102 ...

Page 953: ...Chapter 17 Upgrading ...

Page 954: ......

Page 956: ......

Page 962: ...F 17 4 HDD Boot ROM Flash ROM System Software ...

Page 968: ...F 17 12 ...

Page 998: ...Chapter 17 17 42 F 17 56 2 Select the data to download F 17 57 3 Click Start ...

Page 1001: ...Chapter 18 Service Tools ...

Page 1002: ......

Page 1003: ...Contents Contents 18 1 Special Tools 18 1 18 2 Oils and Solvents 18 2 ...

Page 1004: ......

Page 1007: ...Jan 31 2005 ...

Page 1008: ......