Canon

Booklet Maker Service Support Guide

G. Operator Maintenance

Periodic operator maintenance is required to ensure a specific level of machine

performance. The following tasks should be conducted by the customer

operator(s).

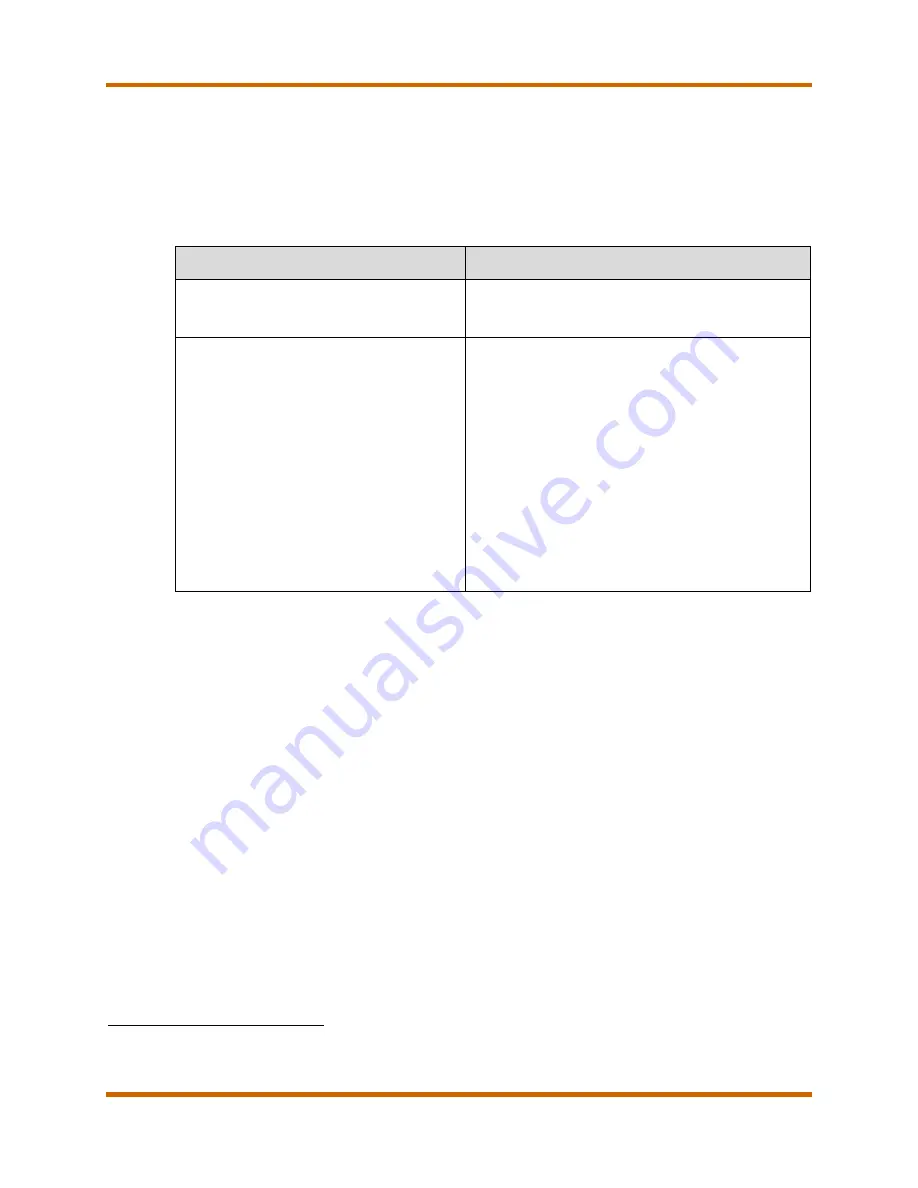

Table 19 – Operator Maintenance

Interval

Task

Weekly

Clean the stitcher head (surface only)

(Tools to perform this maintenance are

included with the ).

Either of the following:

•

Monthly

•

When a new stich wire is installed

•

When the message “OPERATOR

MAINTENANCE”

is displayed

on the screen (approximately

every 20,000 stitches).

•

Lubricate the stitch head (Note: this

should be performed even when the

machine is not in use)

•

Lubricate the stitch head

•

Clean the square spine forming clamp to

prevent stripes appearing on the side of

the booklet spine

•

Clean the square spine form roller to

prevent lines appearing on the booklet

spine

•

Clean trimming removals fingers

•

Clean excess grease from the stitch

head

10

The “OPERATOR MAINTENANCE” message appears after 20,000 stitches and is accompanied by a repeated beeping from

the machine. After another 2,000 stitches the machine locks. Operator Maintenance (including the lubrication and cleaning) will

reset the counter and resume machine operation.

Booklet Maker Service Support Guide

March 2015

Revision 1

Page 16