Page 7 of 11

0 9 / 9 6

PILOT BURNER ADJUSTMENT

The following is a troubleshooting chart of possible problems:

PROBLEM

CORRECTIVE ACTION

Noisy Pilot Flame

Remove pilot adjuster cap, located

next to gas shut off valve. Flame is

decreased by turning adjustment

screw clockwise.

Pilot won’t ignite

Disconnect remote wires and try to

light pilot. If pilot now works,

remote connections are faulty.

Check wiring diagram figure 14.

Main burner will

1. Check wiring (see figure 14.)

not light

2. Check wall switch for proper

connection.

3. Check door safety switch located

center of bottom door rail

4. Burner ignites, adjust activating

pin bottom center of inner glass door.

5. Burner does not ignite, check

electrical contacts of the door safety

switch.

TROUBLESHOOTING

MAINTENANCE

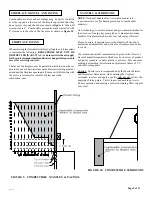

The appliance should be inspected before use and at least annually

by a professional service person. More frequent cleaning may be

required due to excessive lint from carpeting, bedding material,

etc. It is imperative that burner control compartments, burners and

circulating air passageways of the appliance be kept clean. For

your convenience a 1/8" pressure tap is supplied on the gas valve

for a test gauge connection. See Figure 14. For Natural gas the gas

line requires an inlet pressure of 7" W.C. and a manifold pressure

of 3.5" W.C. For Propane gas the gas line requires an inlet pressure

of 11" W.C. and a manifold pressure of 10.5" W.C. Always keep the

fireplace area clear and free of combustible materials, as well as

gasoline and other flammable vapours and liquids.

CLEANING

When fireplace is first activated some smoking and visible film on

the glass may occur, this is a normal condition of heat burning of

protective coatings on new metal.

- Products of combustion do deposit a visable film on the glass

which must be cleaned periodically. Film can easily be

removed by removing inner and outer doors, handling

carefully, and cleaning with normal liquid household products.

WARNING: Do not attempt to clean glass when hot.

Do not clean glass with abrasive materials as any glass

etching may cause premature glass failure.

- Silicone seals on inner door during initial firing will "off gas",

leaving a visual deposit of a white substance on combustion

chamber walls. This can easily be removed using normal

household products.

- Use a vacuum cleaner or whisk broom to keep the control

compartment, burner, and firebox free from dust and lint.

- Logs may be cleaned periodically with soap and water to

remove soot.

CAUTIONS

* Fireplace gas control must be in the “OFF” position and

pilot and main burners extinguished when cleaning

appliance with a vacuum.

* Doors and logs can get very hot, handle only when logs are

cool.

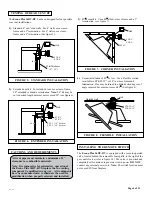

FIGURE 15. PILOT BURNER ADJUSTMENT

3/8 to 1/2 Inch

Power Generator

Pilot

Burner

1. Remove Pilot Adjustment Cap. (see figure 14)

2. Adjust pilot key to provide properly sized flame. See Figure 15

for properly sized flame.

3. Replace pilot adjustment cap.

4. Leak test with a soap solution after installing or servicing with

main burner on. Coat pipe and tubing joints, gasket etc. with

soap solution. Bubbles indicate leaks. Tighten any areas where

the bubbles appear until the bubbling stops completely.

If your Econo Plus 36DV-RV still does not operate correctly,

consult your dealer or the manufacturer.

All service and repairs should be performed by a qualified

agency.

All spare parts, optional fans (see optional fan instruction guide),

and optional trim finishes are available from Canadian Heating

Products Inc. or your local deale

r.

The Econo Plus 36DV-RV has a ten-year limited warranty

on the firebox, a five-year warranty on the main burner, pilot

burner, and cultured oak logs; and a one-year warranty on

the gas control valve and glass doors.

FIGURE 16. WHITE ROGERS GAS CONTROL VALVE