15

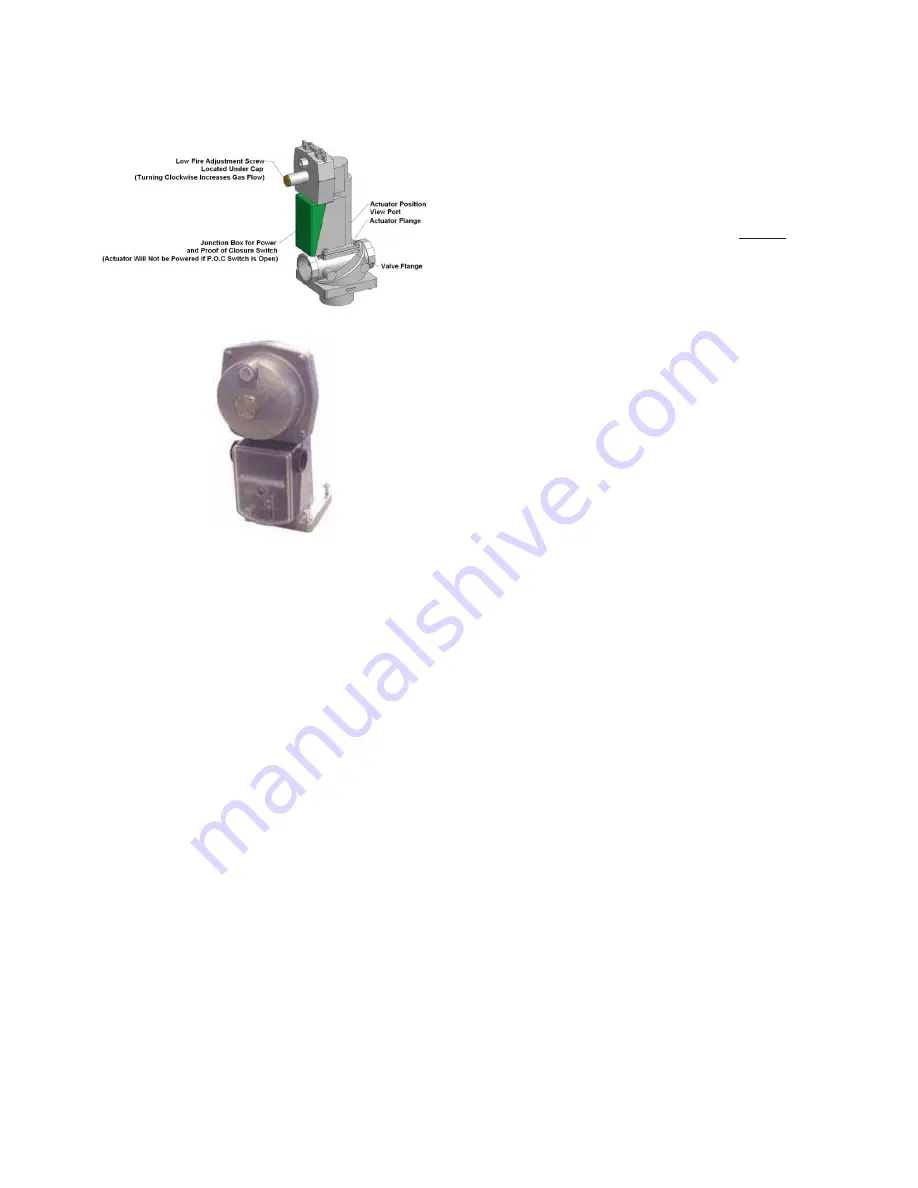

Figure 9: DF2000-60041:1 Air/Gas Ratio Control Valve

Figure 10: DR3500 – 5000 SKP25 Regulating Gas

Valve Actuator &SSOV

3.5 DIFFERENTIAL AIR PRESSURE (DF2000 -6004)

•

The DynaFlame® operates on the principle of differential

pressures. Operation of the fan generates a signal which

is matched on the gas side by the 1 to 1 air/gas ratio

control valve.

•

The differential air pressure measurement is made

between the high and low pressure taps across the fan

discharge and the flue vent. All differential air pressures

are noted at full firing rate. There are two pressure taps at

the fan discharge and care must be taken to tee into the

correct line. The correct line may be identified by tracing it

back to the ratio control valve where the identification of

the tapping is stamped into the die cast actuator.

•

The differential gas pressure measurement is made

between the high and low pressure taps across the in- line

metering gas orifice. Check this value to confirm that it

matches the differential air pressure while the appliance is

firing.

•

The controls on this appliance may fire the burner from

35% up to 100% for non-condensing and from 20% up to

100 % for near-condensing and condensing of rated input.

•

Differential manifold gas pressure will be reduced as

burner input is reduced.

•

All reference gas pressure measurements must be made

at 100% of rated burner input.

•

The differential gas manifold pressure is pre-set at the

factory through the ratio gas valve. Adjustment of manifold

pressure is not normally required for proper operation. In

the field it may be necessary to adjust the low fire

adjustment screw located on the ratio control valve

actuator in order to achieve acceptable light off under soft

start field conditions.

•

Always check settings posted on boiler test label.

3.6

GAS MANIFOLD DIFFERENTIAL

PRESSURE ADJUSTMENT (DF2000 –

DF6004)

Tampering with gas valve adjustments after startup and

commissioning will void the warranty on the gas valve

assembly and the burner.

The appliance’s manifold gas pressure IS NOT field

adjustable after startup and commissioning. The gas valve

pressure ratios have been factory set with an internal bias

adjustment to ensure a 1:1 air/gas ratio on operation.

Tampering with this adjustment by a non-factory trained

technician will void the warranty on the gas valve

assembly and the burner. An appliance supplied with a

properly sized gas line, properly sized meter and a

minimum gas supply pressure (See Table 8 for minimum

allowable inlet gas supply pressure) while firing at full rate

will ensure full burner input. The manifold pressure

supplied to the burner is a differential pressure. This

pressure is the result of the difference in two gas pressure

measurements. A differential manifold gas pressure

measurement should not be made until you have

measured the gas supply pressure. Gas supply pressure

must be at least at minimum allowed with all appliances on

the gas line firing at full rate before a manifold pressure

measurement is made. Use the following procedure to

check gas supply pressure with a manometer connected

to the inlet pressure tap on the gas line connection at the

rear of the appliance.

3.7

CHECKING GAS SUPPLY PRESSURE

•

Turn the main power switch to “OFF” position.

•

Shut off gas supply at the manual gas cock in the gas

piping to the appliance. If fuel supply is LP gas, shut

off gas supply at the tank.

•

Models 500 – 3000: Remove the 1/8" hex plug from

the gas pressure test port located on the inlet gas

supply connection at the rear of the appliance. Install

a fitting in the inlet pressure tapping suitable to

connect to a manometer or magnahelic gauge. Range

of scale should be 0 to 14 inch W.C. or greater to

check inlet pressure

•

Models 3500 – 5000: Remove the 1/8” hex plug

downstream of the SKP25. Install a fitting in the inlet

pressure tapping suitable to connect to a manometer

or magnahelic gauge. Range of scale should be 0 to

14 inch W.C. or greater to check inlet pressure

•

Turn on gas supply at the field installed manual gas

cock; turn on LP gas at tank if required.

•

Turn the power switch to “ON” position.

•

Adjust the thermostat set point to call for heat.

•

Observe the gas supply pressure as the burner fires

at 100% of rated input.

•

Ensure inlet pressure is within specified range.

Minimum and maximum gas supply pressures are

specified in Gas Supply section of this manual.

•

If gas pressure is out of range, contact the gas utility,

gas supplier, qualified installer or service agency to

determine necessary steps to provide proper gas

pressure to the control.

•

If gas supply pressure is within normal range, proceed

to remove gas manometer and replace pressure tap

fittings in the gas piping to the appliance.

•

Turn on gas supply at the manual valve; turn on LP

gas at tank if required.

Summary of Contents for DFH/W500

Page 2: ......

Page 40: ...35...

Page 71: ...66 PART 12 EXPLODED VIEW...

Page 72: ...67 3 44 10 45 46 47 28 31 26 52 57 58 59 54 60 61 SOLA Control Panel 39 4...

Page 82: ...77 PART 13 ELECTRICAL DIAGRAMS...

Page 83: ...78...

Page 85: ...80...

Page 86: ...81...

Page 87: ...82...