10

11. PLACING BOILER IN OPERATION

The Blue-Flame boiler should be installed and started up by qualified personnel.

With the boiler off, open makeup water valve and allow system to fill slowly. Adjust the pressure

regulator to provide at least 15 psig at the highest point in the system.

With all air vents open, run system circulating-pump for a minimum of 30 minutes with the boiler

off.

Open all strainers in the circulating system and check for debris.

Check liquid level in expansion tank. With system full of water at 15 psig, the level of water in

the expansion tank should not exceed 1/4 of the total volume with the balance filled with air.

Start up boiler following instructions provided. Operate entire system including pumps and

radiation for at least 1 hour.

Check water level in expansion tank. If level exceeds ½ of tank volume, air is still trapped in

system. Shut down boiler and continue to run pumps.

Within 3 days of start up, recheck all air vents and expansion tank as described above.

12. CHECK OUT OF IGNITION SYSTEM SAFETY SHUT-OFF DEVICE

After initial fill while the main burner is firing, shut off gas to the pilot and clock the time taken for

the main gas valve to shut down. If the safety control is functioning properly, power to the gas

valve will be shut off within 4 seconds of the pilot gas being shut off. If shut down takes longer,

ignition control or gas valve may be defective.

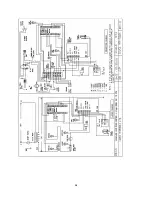

13. LOW WATER TEMPERATURE SYSTEMS

In applications where the heating system requires supply water temperatures below 110ºF, a

bypass line must be installed upstream of the boiler pump so that outlet water can be re-

circulated to raise the inlet temp to a minimum of 110

º

F. Balancing valves, preferably globe

valves are used to adjust flow. (See figure 4)

Summary of Contents for BLUE-FLAME Series

Page 21: ...19...

Page 22: ...20...

Page 23: ...21 21 EXPLODED VIEW...