GSA

Gas-Fired Steam Boilers –

Boiler Manual

9

Part Number 550-110-738/0703

General

3

Install piping

1.

Pipe before installing controls. Connect return piping after jacket

is attached. Connect supply piping before or after jacket is

attached.

Failure to properly pipe the boiler may result in

improper operation and damage to the boiler or

building.

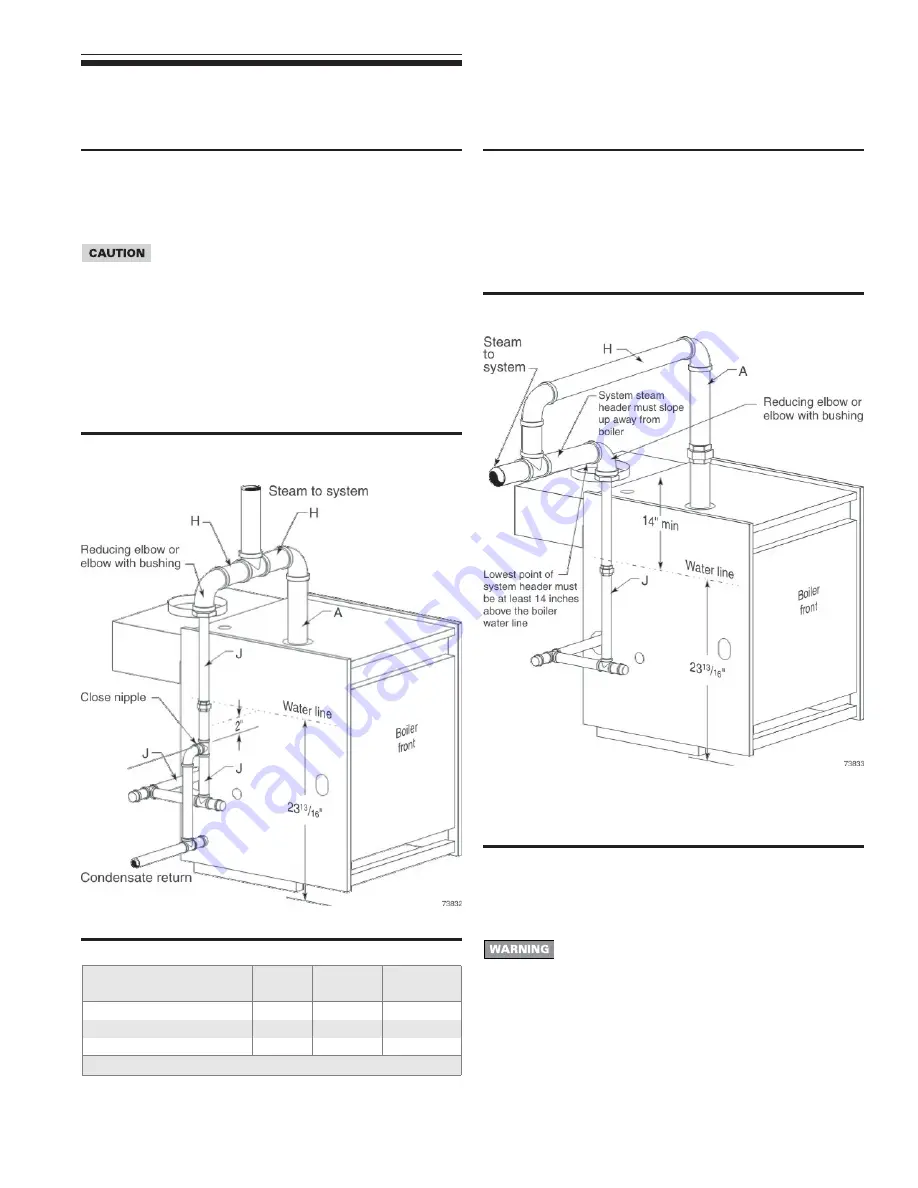

2. See Figure 5 and Table 5. Pipe exactly as shown. Satisfactory

operation of a steam heating system depends on adequate

condensate return to boiler to maintain a steady water level.

Avoid adding raw makeup water. Where condensate return is

not adequate, install low water cutoff/pump control, condensate

receiver and condensate boiler feed pump. Refer to Table 7,

page 10, for sizing. See page 7, Table 4, for tapping locations.

Table 5

Recommended pipe sizing

Boiler model number

Riser (A) Header (H)

see Note

Equalizer (J)

GSA-075 and GSA-100

2"

2"

1½"

GSA-125 through GSA-175

2½"

2 ½"

1½"

GSA-200 and GSA-250

3"

3"

1½"

Note

: 24" minimum from waterline to header.

Figure 5

Recommended piping, piping for parallel-

flow systems only.

Connecting to counterflow piping

Apply the recommended piping in Figures 4 through 7 only when

connecting to a parallel-flow system. When connecting to a

counterflow system, the boiler steam supply must connect into the

top of the counterflow system header, as shown in Figure 6.

Figure 6

Connection to counterflow steam piping

Relief valve

Install relief valve in tapping on top of boiler. See Table 4, page 7,

for control tapping locations. See the tag attached to the relief valve

for manufacturer’s instructions.

Follow the steps below to avoid potential severe

personal injury, death or substantial property damage.

• When installing the relief valve, ensure that all

connections, including the valve inlet, are clean and

free from any foreign matter.

• Mount the relief valve only in the vertical position,

directly connected to the tapping designated in the

manual on top of the boiler.

• Use pipe compound sparingly, or tape, on external

threads only.

• Do not use a pipe wrench! Use proper type and size

wrench on wrench pads only.