24

1005759 ISS 1

OWNER/INSTALLATION MANUAL

12�1 START UP PROCEDURE AFTER WINTERISATION

1. Replace covers (if not fitted).

2. Remove front grille – using soft brush clean finned

surfaces of heat pump. Replace panel.

3. Remove plastic covers on water connections and

reconnect water piping or close drain valve.

4. Start up water circulating pump and leave running

for at least ¼ hour to establish flow and enable any

air in system to escape.

5. Replace fuses to heat pump circuit.

6. Switch on heat pump.

7. Check control thermostat is set to required pool

temperature.

8. Check daily to ensure pool water is at correct pH

and has correct chemical balance.

See section 3.2 Plumbing.

12�0 WINTERISATION PROCEDURE

WARNING. Isolate machine before opening! As heat pump embodies electrical and rotational

equipment, it is recommended for your own safety that a competent person carries out the

following procedure.

(Drain Down Procedure)

ALL MODELS

Objective

To provide frost protection

To eliminate corrosion problems

To inhibit electrical components

1. Switch off electrical supply to heat pump.

2. Remove external fuses and keep in safe place away

from heat pump to prevent accidental operation of

heat pump.

3. Ensure water circulation pump is switched off.

4. Drain water from heat pump by:

a) Drain valve if fitted.

b) Disconnecting pipework to and from heat pump.

c) Remove condenser drain down cover.

d) Flush through water circuit in heat pump by using

CLEAN TAP WATER (NOT POOL WATER) via hose into

outlet connection – run for 10 minutes minimum, use

spray nozzle if available.

e) Allow to drain – fit plastic bags secured by elastic

bands over water connections.

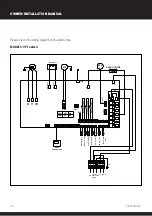

5. Uncover electrical enclosure (page 13) and

liberally spray interior of unit, with moisture repellant

aerosol WD-40 or similar, reseal enclosure.

6. If heat pump located outside, protect from weather

by covering with VENTILATED cover. A bespoke

cover is available. Do not use plastic sheet as

condensation can occur within unit.

If this procedure is not adopted and frost or corrosion damage results

then the warranty will become invalid.