Page 6

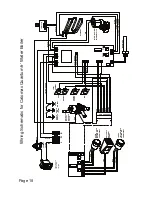

ELECTRICAL CONNECTIONS

The boiler is supplied with a fitted plug and lead and should be plugged

into a 240v 13A electrical socket, capable of carrying a load of 3kW. The

installation of a residual current device (RCD) having a rated residual

operating current not exceeding 30 mA is advisable

.

USER INSTRUCTIONS

During normal operation some external parts will become

hot. Care must be taken to avoid injury, a burn or scald.

Commissioning

1.

Turn water supply on

2. Turn electrical supply on

On initial switch-on only

After a few seconds delay for the electronics to charge up, the boiler will

begin filling with water and the ‘Ready’ light will flash to indicate wait. If the

key switch is in the ‘on’ position the push button will flash to indicate wait,

at this point the button is disabled. When water reaches the low level sensor

(element covered) the element will be energised as well as the solenoid.

When the selected operating level is reached the solenoid will turn off and

the element will remain on until full operating temperature is reached.

With the key switch in the ‘ON’ position the push button will stop flashing

and show solid colour when the boiler is up to full temperature and the

button will be enabled, at this point the ‘ Ready’ light will stop flashing and

show solid colour and the ‘Full’ light will also be illuminated.

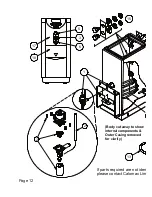

VENT & OVERFLOW

The vent / overflow pipe must be extended and laid with a

continuous

fall

,

discharging to a safe and visible point. The pipe should not be directly

connected to a closed waste, as taste problems may occur and should

never be allowed to become blocked or restricted. One way this could

be connected is via a tundish arrangement. 15mm copper or ‘Speedfit’

pipe should be used. If the machine is operated without the overfill pipe

being extended as advised, any subsequent damage incurred will be the

responsibility of the installer.